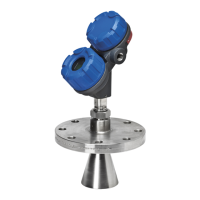

What does '2nd Float Missing' mean on my Magnetrol Measuring Instruments?

- HhbuckleySep 9, 2025

The '2nd Float Missing' error means that the echo curve rises above the threshold only once. Check the Measurement type, increase the Gain/Sensitivity Settings, and verify that two floats are present. Consult Factory if the issue persists.