___

Reparaturanleitung PS-4600 / PS-5000 20

Repair manual DCS3500 / DCS3501 / DCS4300 / DCS4301 / EA3500F / EA3501F / EA4300F / EA4301F / MEA3500L / MEA3500M / MEA4300G / MEA4300L

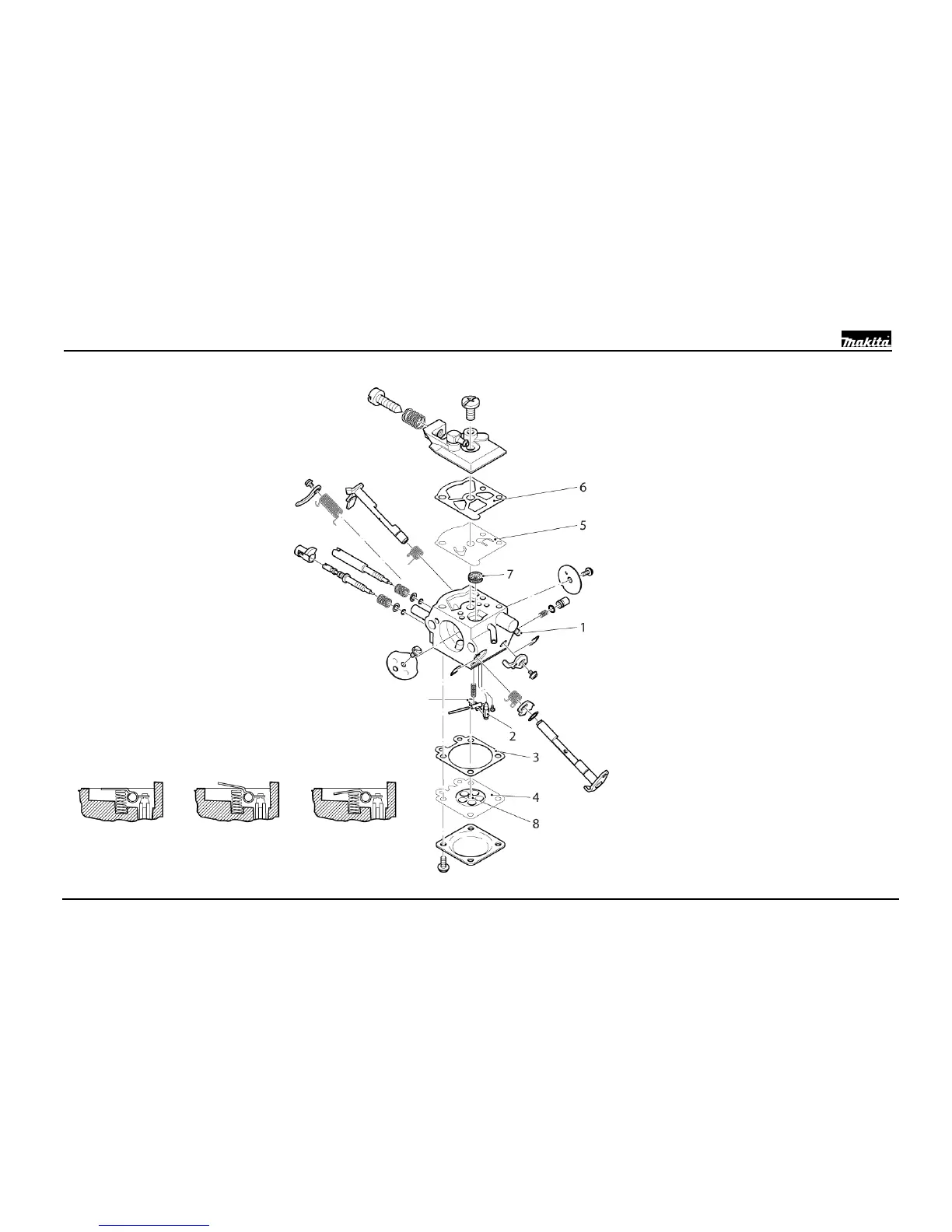

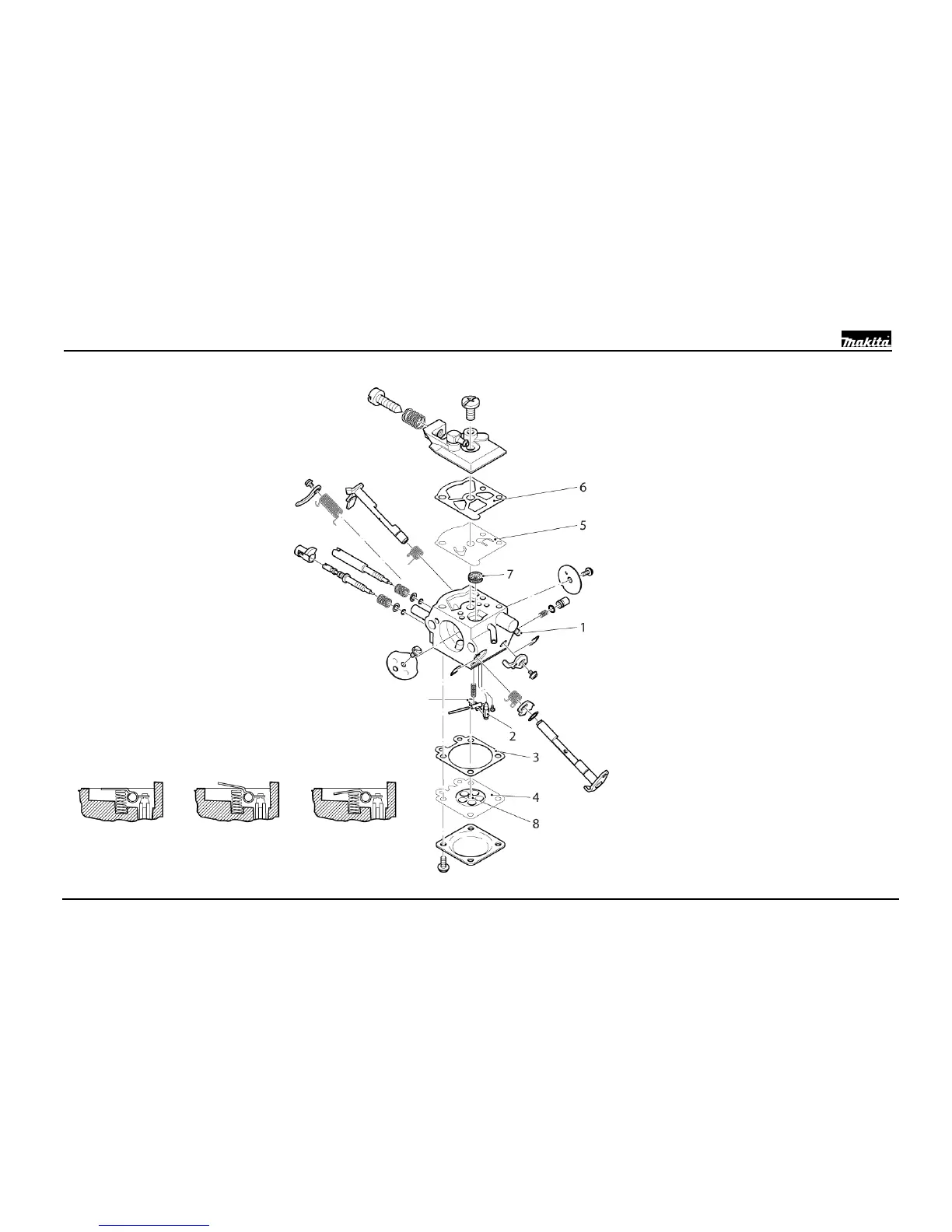

• Screen 7 for contamination

• Pulse hole for contamination

Check control parts

(control lever/inlet needle):

Check the tip of the inlet needle for wear.

Check control lever for correct installation, see

illustration to the left.

If the control lever is too low:

• Lack of fuel

• Poor acceleration

• No maximum power

If the control lever is too high:

• Carburetor flooding

• Starting problems

• Poor idling

•

Poor transition

Check the pump diaphragm:

•

If pump diaphragm is dented, torn, or creased,

• If valve flaps are bent,

replace the diaphragm and gasket

Check control diaphragm:

• If control diaphragm i

is obvious wear at the button 8.

• If it does not return to its original position

when pulled out of it,

replace the diaphragm and gasket.

L= 1 1/2

H= 3

NOTE: Adjust the carburetor only

using a tachometer.

Pressure test

Connect the pressure gauge (chapter

00 item 8 oder 13) to the carburetor

fuel connection 1.

Set up a pressure of max. 0.5 bar.

If the pressure falls, check the

following parts:

•

Correct assembly of Control assy

(Control lever, Inlet needle, Lever

spring, lever axle)

•

Check seat of inlet needle for

dirt/foreign parts, clean if necessary

•

Replace control assy

• Replace gasket 6 and diaphragm 5

of the pump side

Loading...

Loading...