8 ENGLISH

Reversing switch action

►Fig.6: 1. Reversing switch lever

CAUTION: Always check the direction of rota-

tion before operation.

CAUTION: Use the reversing switch only after

the tool comes to a complete stop. Changing the

directionofrotationbeforethetoolstopsmaydam-

age the tool.

CAUTION: When not operating the tool, always

set the reversing switch lever to the neutral

position.

Thistoolhasareversingswitchtochangethedirection

of rotation. Depress the reversing switch lever from the

AsideforclockwiserotationorfromtheBsideforcoun-

terclockwise rotation.

When the reversing switch lever is in the neutral posi-

tion,theswitchtriggercannotbepulled.

Speed change

►Fig.7: 1. Speed change lever

CAUTION: Always set the speed change lever

fully to the correct position. If you operate the

tool with the speed change lever positioned halfway

betweenthe"1"sideand"2"side,thetoolmaybe

damaged.

CAUTION: Do not use the speed change lever

while the tool is running.Thetoolmaybedamaged.

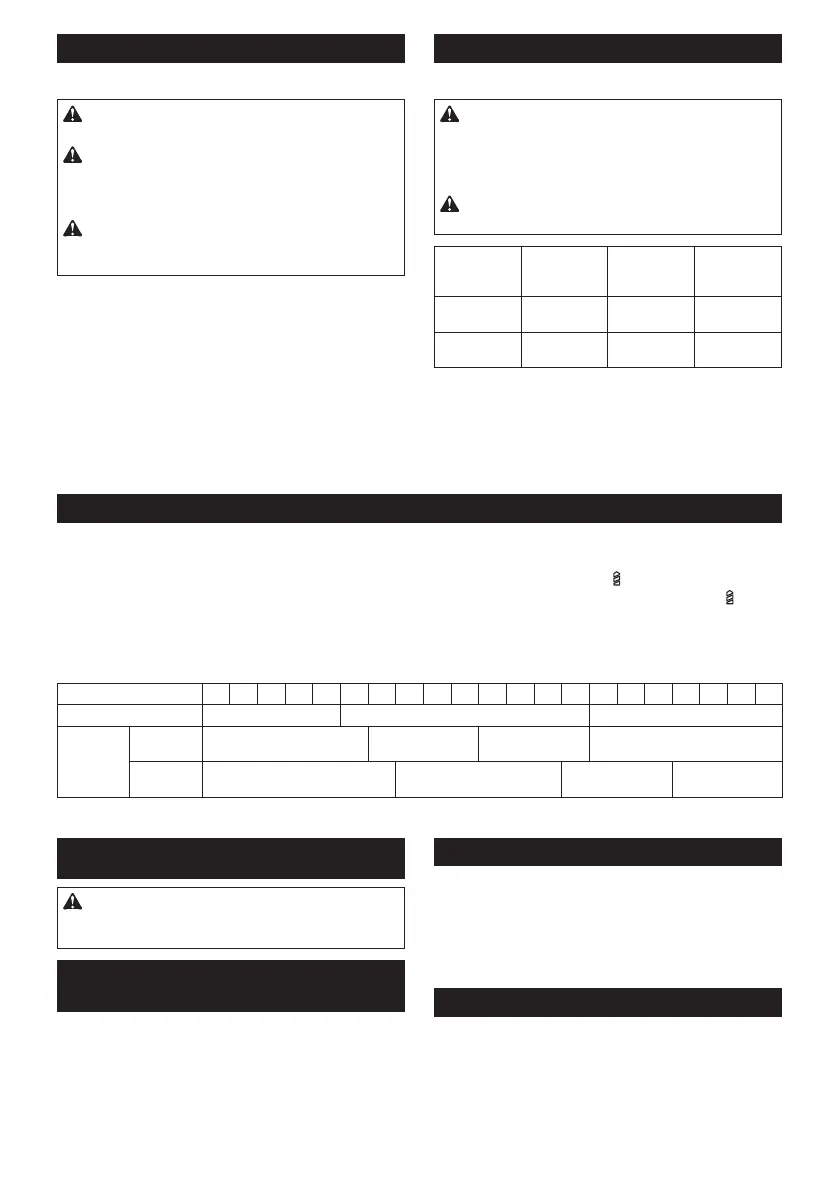

Position of

speed

change lever

Speed Torque Applicable

operation

1 Low High Heavy load-

ing operation

2 High Low Light loading

operation

Tochangethespeed,switchoffthetoolrst.Select

the"2"sideforhighspeedor"1"forlowspeedbuthigh

torque.Besurethatthespeedchangeleverissettothe

correctpositionbeforeoperation.

If the tool speed is coming down extremely during the

operationwith"2",slidethelevertothe"1"andrestart

the operation.

Adjusting the fastening torque

►Fig.8: 1.Adjustingring 2.Graduation 3.Arrow

Thefasteningtorquecanbeadjustedin22stepsbyturningtheadjustingring.Alignthegraduationswiththearrow

onthetoolbody.Youcangettheminimumfasteningtorqueat1andmaximumtorqueat

marking.

Theclutchwillslipatvarioustorquelevelswhensetatthenumber1to21.Theclutchdoesnotworkatthe

marking.

Before actual operation, drive a trial screw into your material or a piece of duplicate material to determine which

torquelevelisrequiredforaparticularapplication.

Thefollowingshowstheroughguideoftherelationshipbetweenthescrewsizeandgraduation.

Graduation 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Machine screw M4 M5 M6

Wood

screw

Soft wood

(e.g. pine)

– ɸ3.5 x 22 ɸ4.1x 38 –

Hard wood

(e.g. lauan)

– ɸ3.5 x 22 ɸ4.1x 38 –

ASSEMBLY

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before carrying out any work on the tool.

Installing or removing driver bit/

drill bit

►Fig.9: 1. Sleeve 2. Close 3. Open

Turnthesleevecounterclockwisetoopenthechuck

jaws.Placethedriverbit/drillbitinthechuckasfar

asitwillgo.Turnthesleeveclockwisetotightenthe

chuck.Toremovethedriverbit/drillbit,turnthesleeve

counterclockwise.

Installing hook

►Fig.10: 1. Groove 2. Hook 3. Screw

Thehookisconvenientfortemporarilyhangingthetool.

Thiscanbeinstalledoneithersideofthetool.Toinstall

the hook, insert it into a groove in the tool housing on

eithersideandthensecureitwithascrew.Toremove,

loosen the screw and then take it out.

Installing driver bit holder

Optional accessory

►Fig.11: 1.Driverbitholder 2.Driverbit

Fitthedriverbitholderintotheprotrusionatthetoolfoot

on either right or left side and secure it with a screw.

Whennotusingthedriverbit,keepitinthedriverbit

holders.Driverbits45mm-longcanbekeptthere.

Loading...

Loading...