P 3/ 7

R

epair

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Drill chuck

DISASSEMBLING

DISASSEMBLING

1R223

1R224

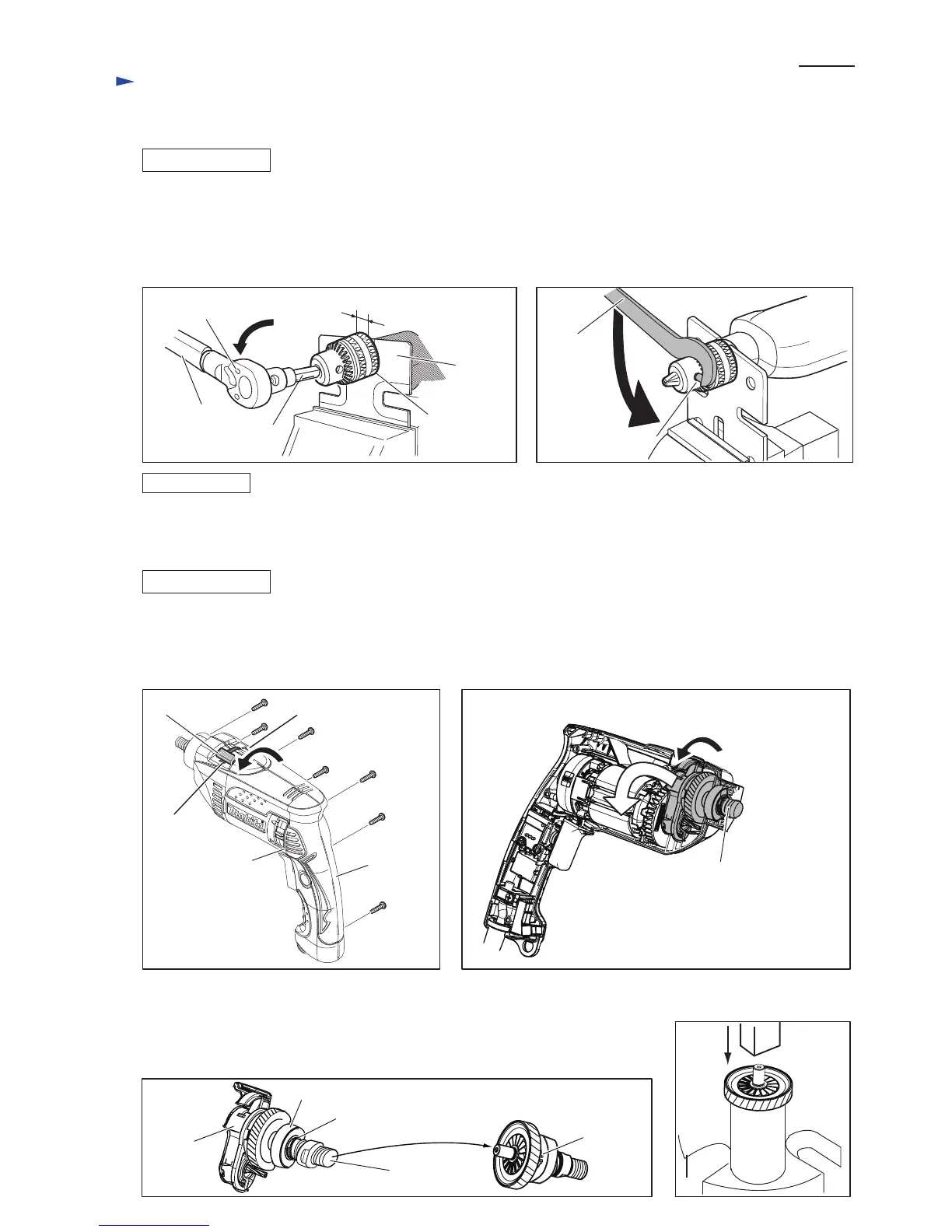

Fig. 2 Fig. 3

1R298

1R139

Drill chuck

vise

1) Hold 1R298 with Drill chuck.

2) Clamp 1R139 in vise so that flats of Spindle can be fit into 14mm width groove of 1R139.

3) Turn Drill chuck counterclockwise using 1R223, 1R224 and 1R298. (Fig. 2)

Note: If Drill chuck does not work, insert the hook of 781024-2 to a hole of Drill chuck,

then turn Drill chuck counterclockwise. (Fig. 3)

Take the disassembling step in reverse.

Note: Pre-set the fastening torque of 1R223 to 34.3 up to 44.1N.m.

Change lever

(shifted to hammer

drill mode)

1R165

Spindle section

(Spindle, Compression spring 15,

Ball bearing 6002LLB, Retaining ring S-15,

Helical gear 45, Change lever, Steel ball 5.0,

Plate 19, Cam holder complete)

ASSEMBLING

14mm

[3]-2. Carbon brush, Helical gear 45, Ball bearing 6002LLB

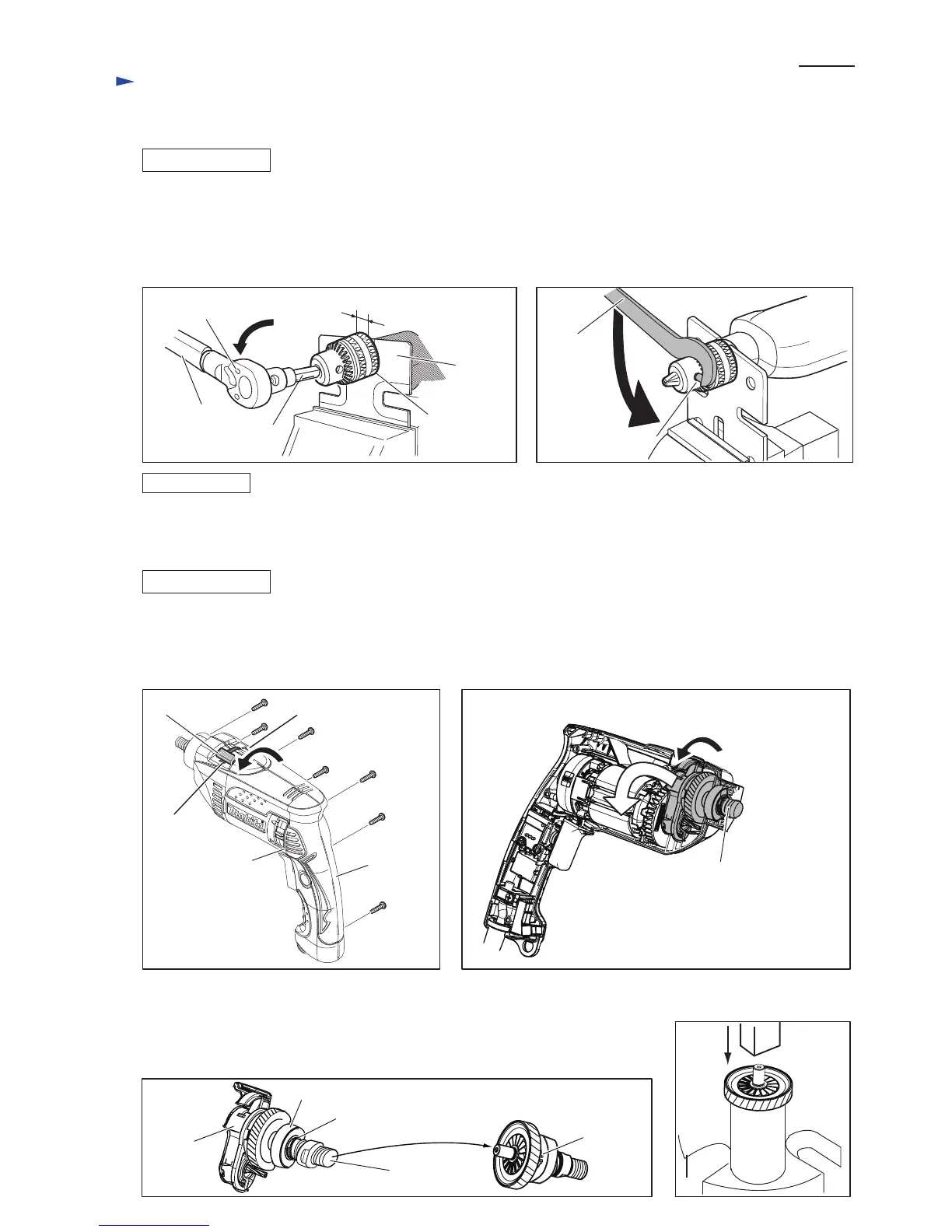

1) Shift Change lever to Drill mode. (Fig. 4) Then separate Housing R from Housing L by removing 4x18 Tapping screws.

Carbon brushes can be removed from Brush holder unit.

2) Shift Change lever to hammer drill mode. Pick up Spindle and Change lever then pivot the Spindle section along

the arc illustrated in Fig. 5.

3) Remove Cam holder complete from Spindle section by pulling Spindle. (Fig. 6)

4) Applying 1R165 to Helical gear 45, press Spindle to remove Helical gear 45. (Fig. 7)

5) Remove Retaining ring S-15 with 1R291. Ball bearing 6002LLB and Compression

spring 15 can be removed.

Housing R

Housing L

4x18 Tapping

screw (7pcs.)

Change lever

Drill mode

Hammer drill mode

Fig. 4

Fig. 7

Fig. 5

Fig. 6

Cam

holder

complete

Spindle section except

Cam holder complete

Ball bearing 6002LLB

Spindle

Retaining

ring S-15

Compression spring 15

781014-2

hole of Drill chuck

Loading...

Loading...