4

5

Replacing cylinder liners

113

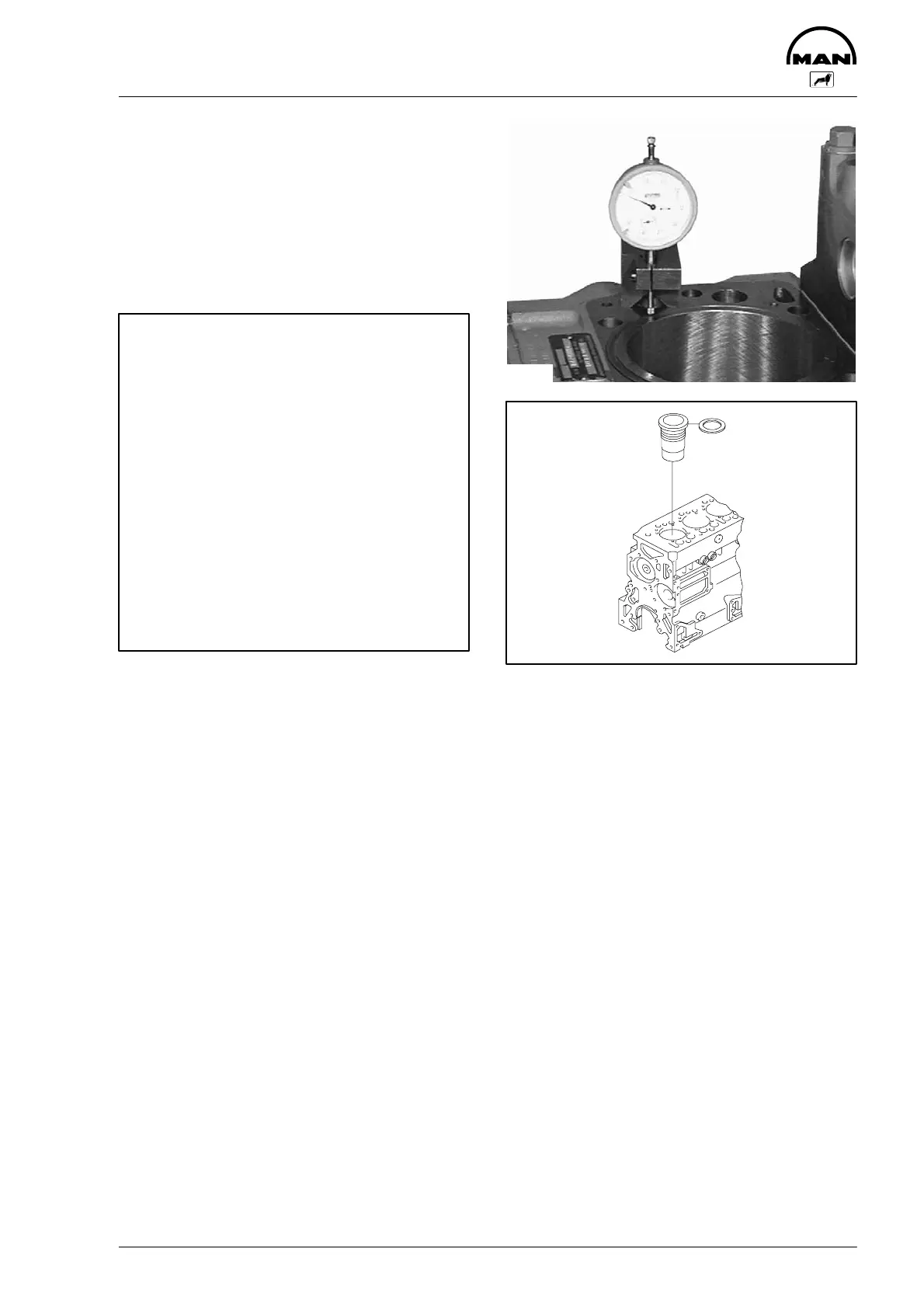

Checking cylinder liner protrusion

Fig. 4

Clean basic bore and cylinder liner.

Insert cylinder liner without O-rings into crankcase,

observing the marking (ensure that it is identical

with the position prior to removal).

Measure cylinder liner protrusion at at least four

different points, using gauge holder and gauge.

Note:

If available, use measuring plate for the

measurement (special tool, see page 132)

Proceed as follows:

Position press-on measuring plate (1) with

turned collar facing the liner using 2 fitting

sleeves to centre plate.

Tighten 4 bolts (2) (improvised: collar bolt

51.90020-0270, length shortened to 90 mm)

on the press-on measuring plate in stages

and crosswise to 40 Nm.

Set dial gauge combination above press-on

plate to - 0 - under preload relative to the

crankcase.

Measure cylinder liner protrusion at least at

four points.

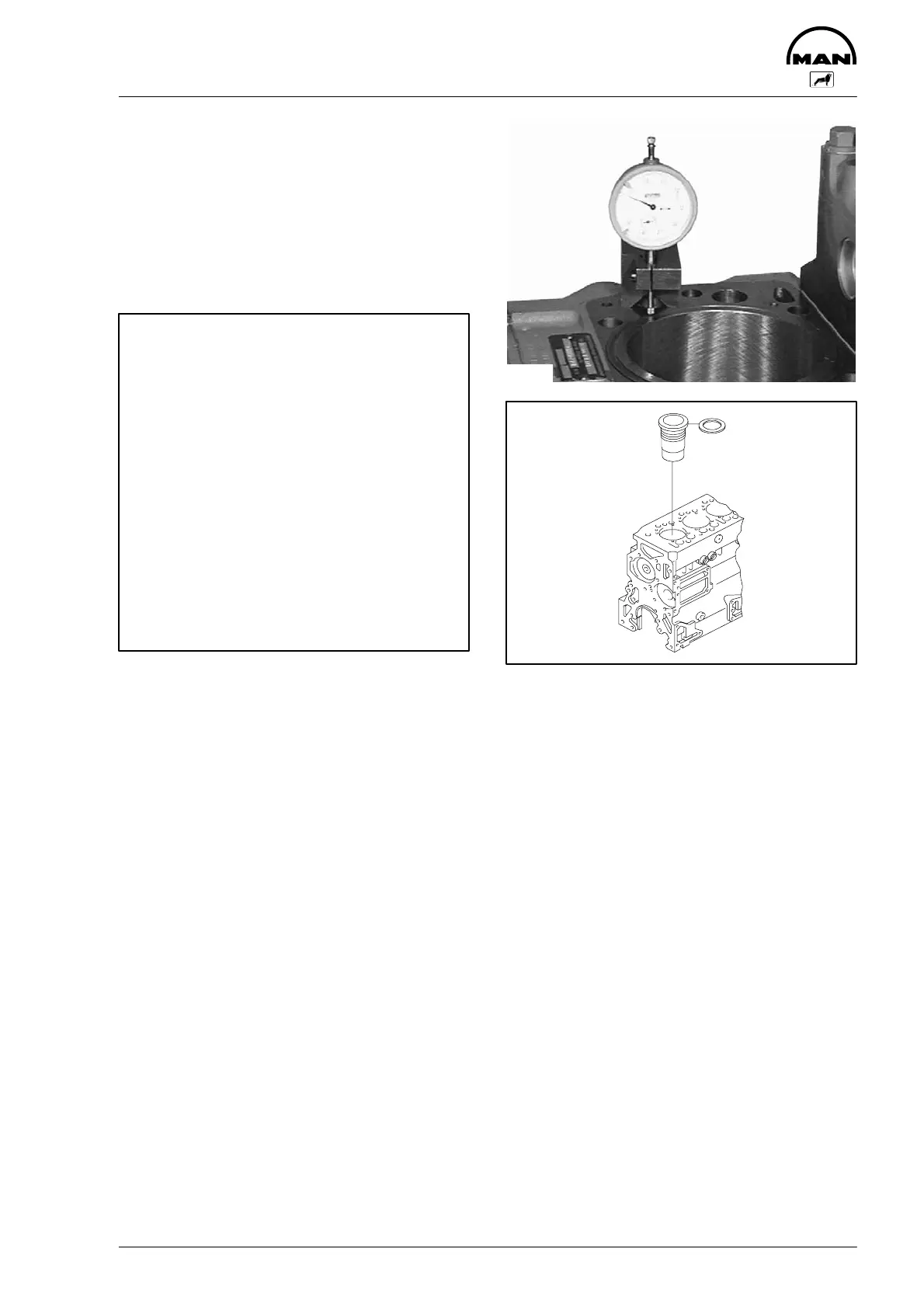

Fig. 5

Install shim if the protrusion is below the minimum

protrusion even at only one point.

The shim is placed under the cylinder liner collar.

However, it may be used only if after installation

the upper tolerance limit is not exceeded.

3573

Loading...

Loading...