www.mc-techgroup.com CG-2 | 1.04.00 15

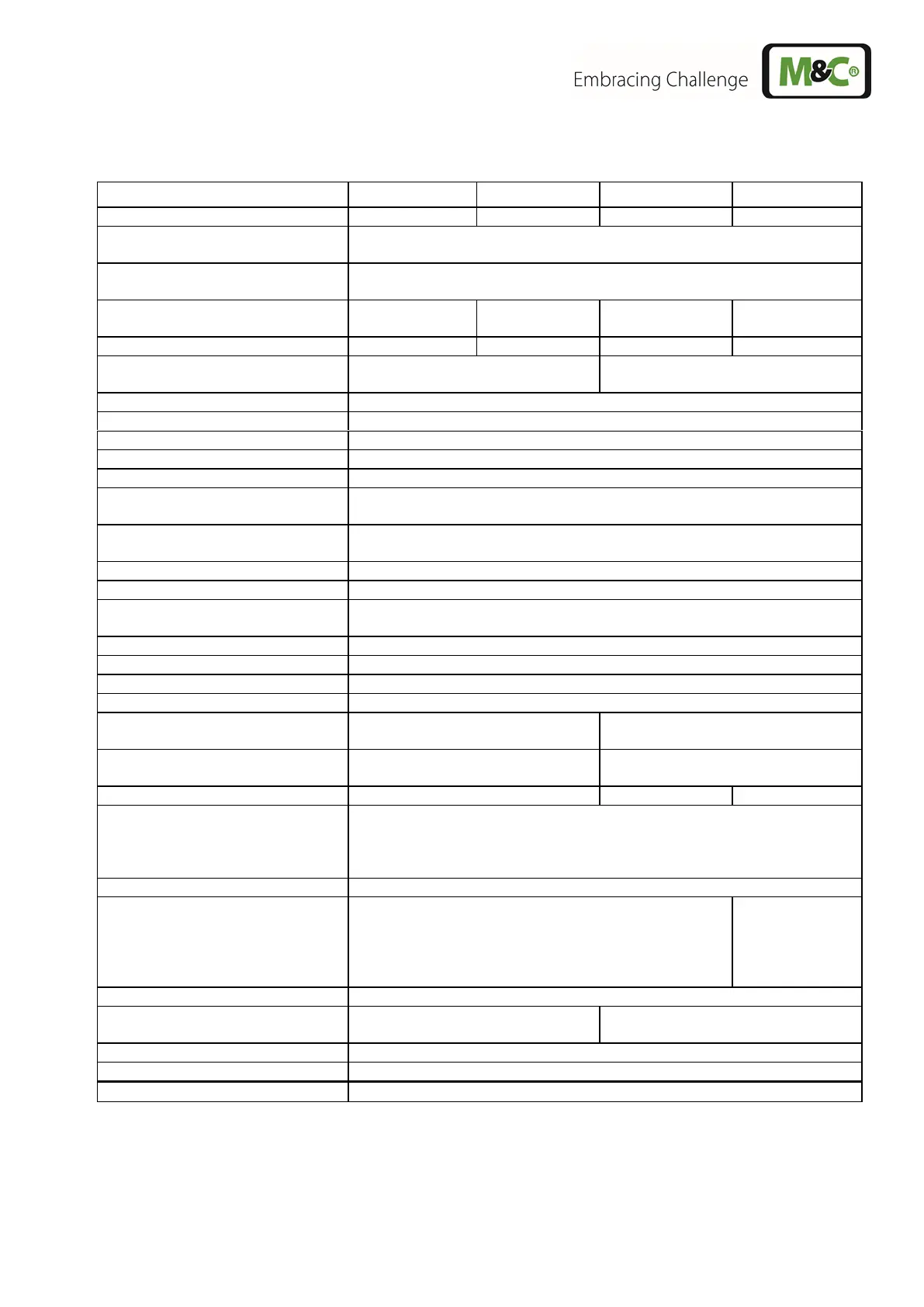

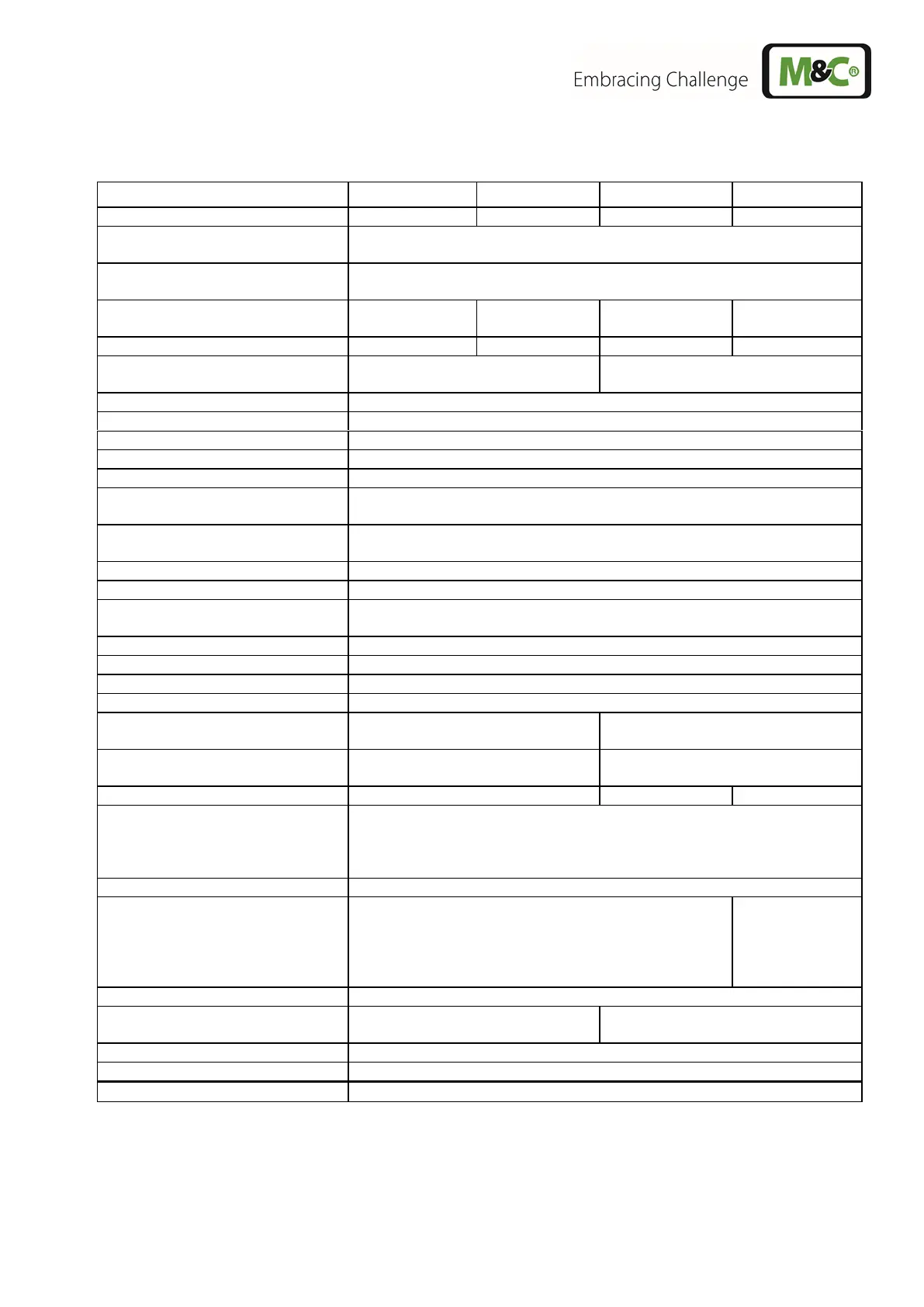

9 TECHNICAL DATA

Part-No.Converter cartridge Type

C Carbon-Molybdenum

Part-No.Converter cartridge Type

SS metallic Filling

Gas inlet and –outlet non-heated

(cold) or heated (hot)

Max. +80 °C [176 °F],

dew point “dry“

Max. +250 °C [482 °F],

dew point <160 °C [320 °F]

Temperature range, adjustable

30 to 60 Nl/h, max. 90 Nl/h

Max. 2 bar abs. (pressure deviations only with max. 0.1 bar/min)

Volume of the converter cartridge

Operating temp. converter car-

tridge type C

Min. 320 °C [608 °F] typ. 350 °C [662 °F] max. 380 °C [716 °F]

Operating temp. converter car-

tridge type SS

Min. 620 °C [1148 °F] typ. 660 °C [1220 °F] max. 680 °C [1256 °F]

200 ppm (type C), 2000 ppm (type SS) at new catalyst

Conversion rate NO

2

in NO

Effectiveness > 95 % for a new catalyst

Service life of the NO

2

/NO catalyst

Change as a preventive measure every 6 months for type C**

Change as a preventive measure every 12 months for type SS**

< 20-60 mbar depending on type

+10 to +50 °C [50 to 122 °F]

-25 to +65 °C [-13 to 149 °F]

Connection sample gas inlet and

outlet

PVDF-fitting G1/4 i DIN 228/1

ø6 mm tube fitting, 1.4571*(316Ti*)

230 V 48-62 Hz

or 115 V 48-62 Hz (a)

230 V 48-62 Hz

or 115 V 48-62 Hz (a)

Mains power plug connector incl. 2 fine fuses 5 x 20 mm,

230 V / 3.15 A

TT

or 115 V / 6.3 A

T

,

2 m [approx. 6.56 ft] cable with shockproof plug.

Alarm- and control signals 9 pin Sub-D-connector

Status signals for temperature

1 Contact potential free, max. contact rating 24 V,

1 A

Material of sample contacting parts

Stainl. Steel SS316Ti, PTFE, FPM, PVDF

Stainl. Steel

SS316Ti, PTFE,

FPM, PVDF, alu-

minium hard-

coated

19" rack mounting,

3U, depth 350 mm [13.78”]

Wall mounting,

height 350 mm [13.78”], depth 3U

Electrical equipment standard

Option for CG-2 and CG-2M

Mounting bracket, 3U – 84HP, Part No.: 50A3000

* Standard ø 6 mm connection, optional ø ¼“ – please indicate with order.

** The indicated service life of 6 respectively 12 months is the minimum service live of the catalyst material under

normal conditions and in not highly corrosive, reducing or oxidizing atmospheres. The operator is responsible for

checking and, if necessary, adjusting the life cycles.

Loading...

Loading...