3-20

E

EVERY 1000 HOURS OF OPERATION

E1 - Movement speeds (*)

CHECK

E2 - Condition of the flexible tubing and rubber hoses

CHECK

- Check the apparent condition (crazing) of the hoses subject to UV and thermal stresses; their

technical characteristics may have been altered (porous spots).

PAY ATTENTION TO ANY LEAKS

H

ydraulic oil escaping under high pressure can penetrate the skin and cause

severe injuries. If you are injured by a jet of high-pressure oil, contact a doctor

immediately.

If you think there may be a leak, do not look for it with your hand; check with a

piece of cardboard, while protecting your hands and your body.

For your safety’s sake, replace the worn hoses.

E3 - Condition of the cylinders (leaks, cylinder rods)

CHECK

- Check the condition of the cylinders. There must not be any:

• Hydraulic leaks from the seals and the valve blocks

• Impacts on and around the cylinder rods

E4 - Condition of the cables and cable bundles

CHECK

- Check that the Earth loop is present under the chassis and its condition.

- Inspect the following sectors while checking the state of the bundles: no deterioration or

looseness:

• Base control console,

• Hydraulic power unit module plate,

• Battery,

• Scissors,

• Basket control console.

- Check that there is electrical grease in the following locations:

• Between the ECM and the basket console

• All the connectors

• The tilt

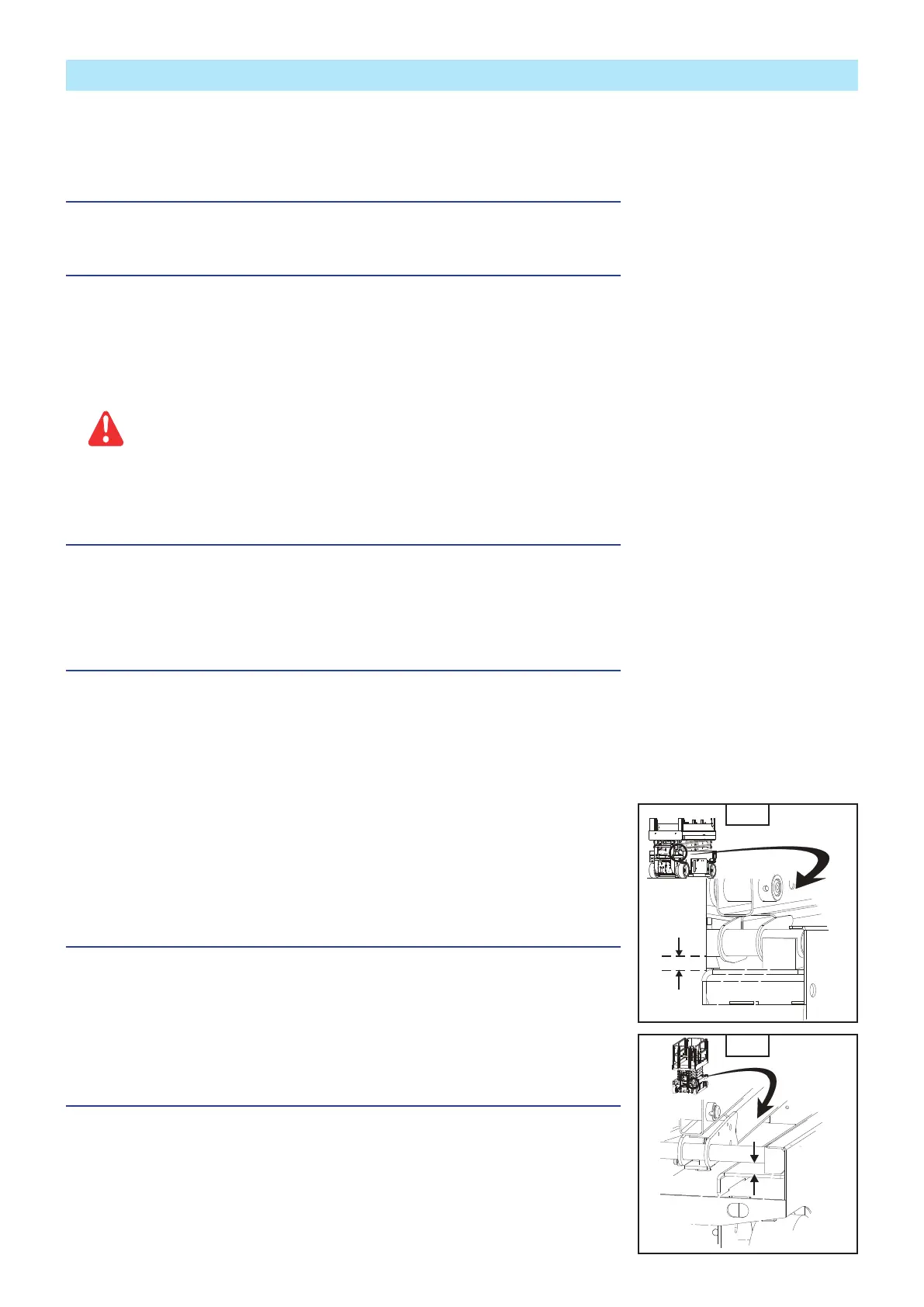

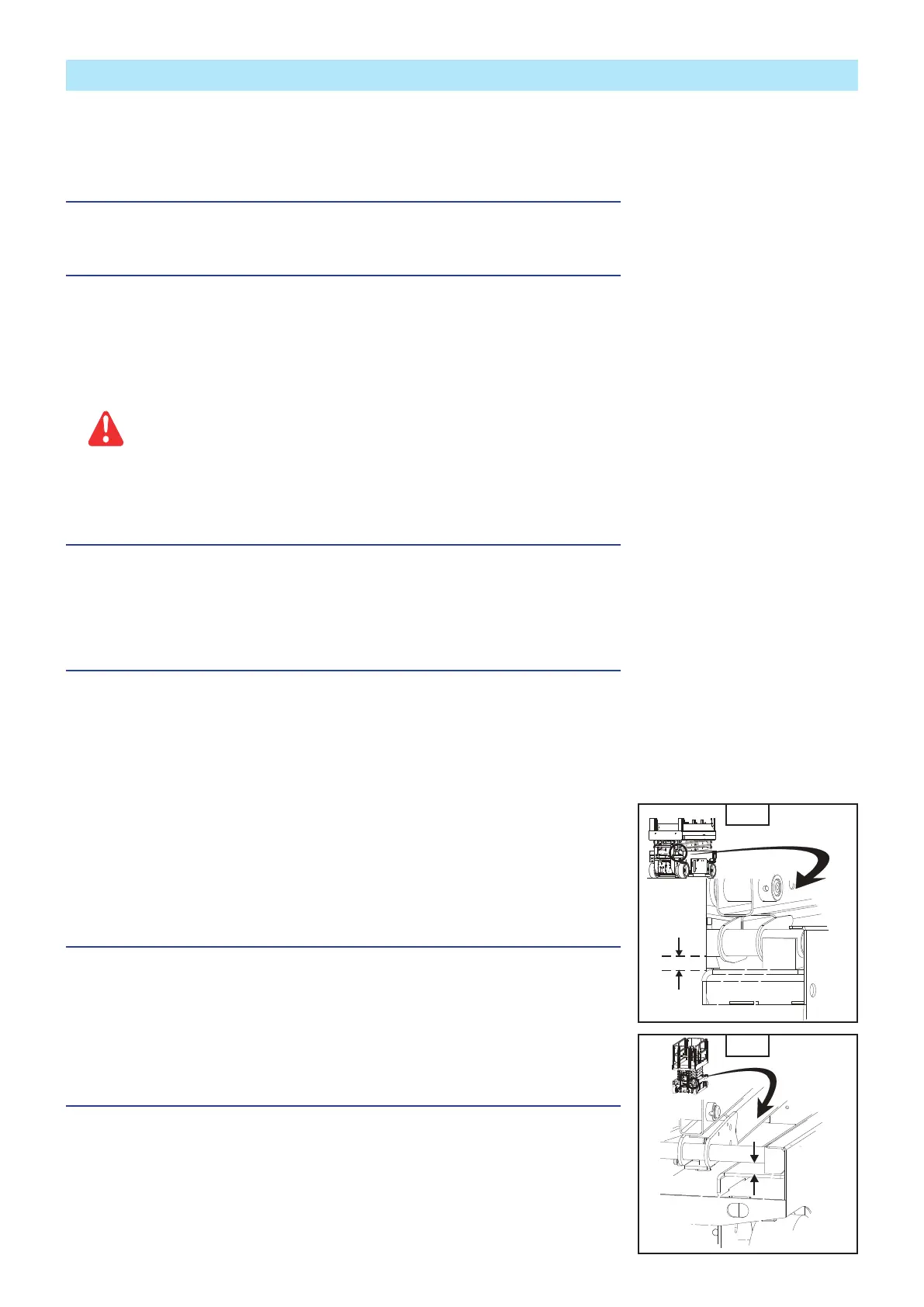

E5 - Scissors skid

CHECK

- Measure the distance between the lower tube on the scissors and the chassis (Fig. E5-1 and

E5-2)

> Result for 78 SEC : equal to or greater than 22.9 mm. If the result is lower, replace the skids.

> Result for 100 SEC - 120 SE : equal to or greater than 22.4 mm. If the result is lower, replace

the skids.

E6 - Translation motor

CHECK

- Check that there are no oil leaks from the translation motor.

*(Contact your dealer)

78 SEC

E5-1

100 SEC

120 SE

E5-2

647369 (01/03/2017)

78/100 SEC 2 / 120 SE 2

Loading...

Loading...