Grove Published 07-06-2017, Control # 406-03 3-25

CD5520/YB5520 OPERATOR MANUAL OPERATING CONTROLS AND PROCEDURES

Hoist Operation

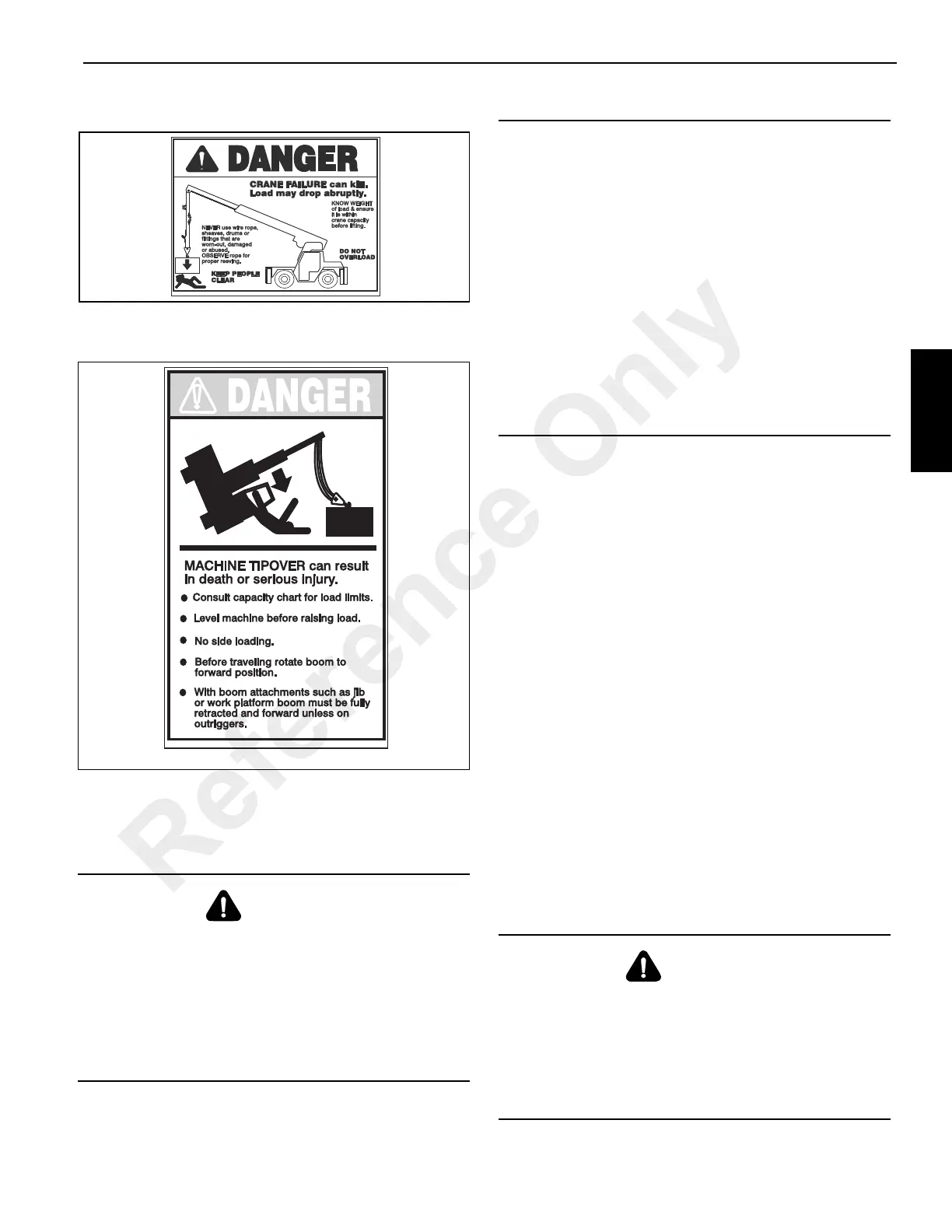

Before making a lift, be sure all persons are clear of the load.

A falling load can cause injury or death.

Know the capacity of the crane. The operator must be

familiar with the crane’s capacity chart before lifting a load.

See Capacity Chart, page 4-1. A falling load or crane tip-over

can cause injury or death.

To Raise the Hookblock

1. With the Hoist Speed Select Switch, press the top for

high speed or the bottom for low speed hoist operation.

2. Press the accelerator pedal to increase the engine

speed to maximum rpm.

3. Slowly pull back on the hoist control lever (Figure 3-36)

until the desired raising speed is obtained. The further

the control is pulled back the faster the hookblock will

raise

To Stop Hoist Rotation

Slowly move the control lever to the neutral position and

decrease the engine speed to idle.

To Lower the Hookblock

1. With the Hoist Speed Select Switch, press the top for

high speed or the bottom for low speed hoist operation.

2. Press the accelerator pedal to increase the engine

speed to maximum rpm.

3. Slowly push forward on the hoist control lever

(Figure 3-36) until the desired lowering speed is

obtained. The further the control is pushed forward the

faster the hookblock will lower.

WARNING

When lifting a load, keep your eyes on the load at all

times. If you must look away, stop the movement of the

load first. A moving load can cause injury or death.

Always have a flagman give assistance if you can not see

a moving load. Be sure you can see the flagman at all

times. Agree in advance to hand signals to be used (see

Hand Signals, page 2-36). A moving load can cause injury

or death and/or property damage.

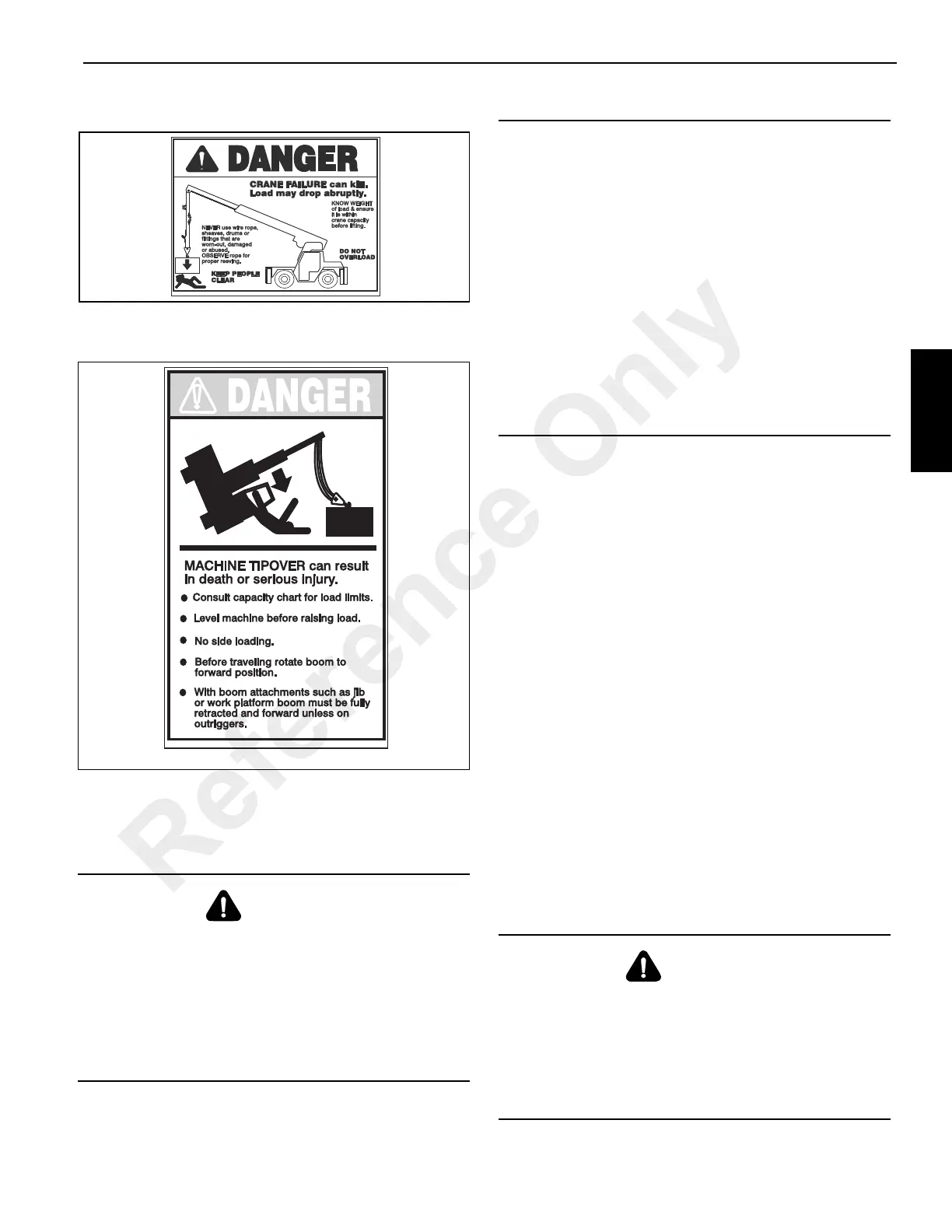

CAUTION

Never put side loads on the boom. Side loads can

damage the swing gearbox. Move the boom so that it is

directly above the load before lifting the load.

Do not let the hookblock touch the boom head. An

automatic cutout device is installed on this crane to

prevent the hookblock from being pulled into the boom

head. When the hookblock touches the anti-double

blocking bracket (Figure 3-33) hanging from the boom

head, a switch is activated and the hydraulic flow to raise

the drop block is stopped. A horn will sound, warning the

operator that the block has touched the bracket. The

operator must then lower the hookblock to stop the horn

and allow for other boom functions.

The above information also pertains when a boom

extension is attached to the boom.

WARNING

When lifting at high boom angles with an extended boom,

it is crucial to maintain proper side slide pad adjustment.

See Boom Adjustments in the Service Manual. Visually

check the lateral straightness of the boom before raising

the load. Lifting with a boom which is not visually straight

may cause boom failure and could result in injury or

death.

Reference Only

Loading...

Loading...