Lubrication Guide MLC300

F2280-2

Published 07-21-21

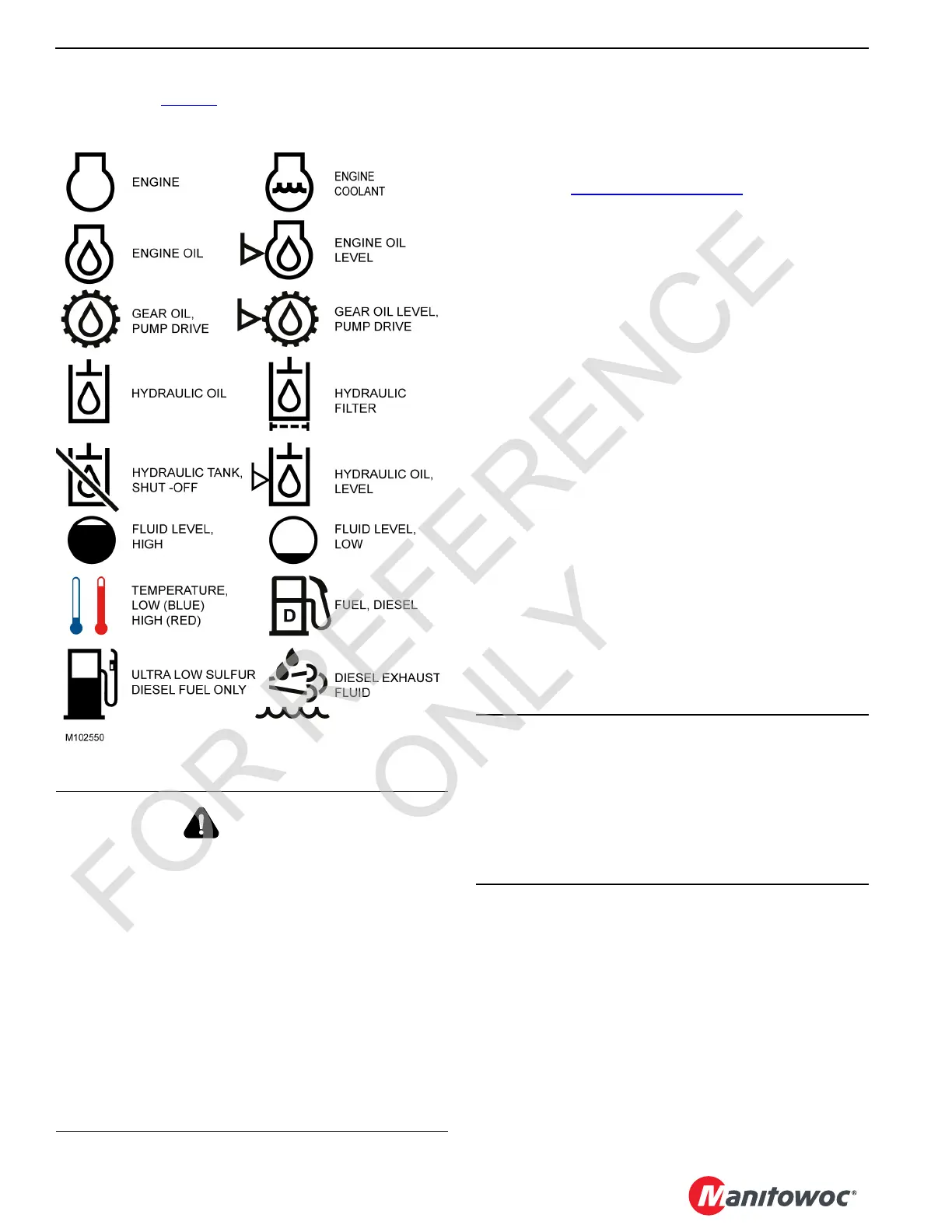

LUBRICATION SYMBOLS

The symbols in Figure 1 are used in decals on the crane to

identify lubrication points.

GENERAL LUBRICATION

This publication describes the major lubrication

considerations for this crane. Some points requiring

lubrication (for example, the linkage in control members not

equipped with grease fittings) have been omitted, but they

should be lubricated in accordance with good maintenance

practices (see “

Oil Can Points” on page 3).

The lubrication intervals for vendor-supplied parts (engine,

light plant, etc.) have also been omitted from this Lubrication

Guide. Service vendor-supplied parts according to the

original equipment manufacturers’ manuals.

Depending on the options your crane is equipped with, some

lubrication points given in this Lubrication Guide may not

apply to your crane.

LUBRICATION INTERVALS

The intervals listed in this Lubrication Guide are for average

operating conditions based on experience gained by

testing lubricants at the factory and on recommendations

given by the lubricant suppliers. Severe operating conditions

(such as excessively dusty or corrosive atmosphere,

unusually high or low outside temperature, extreme

loadings, uncommonly frequent or long operating cycles)

may require shortening the lubrication intervals. Follow the

intervals given in this Lubrication Guide until adequate

experience is obtained to establish intervals which meet your

operating conditions.

Bearings and bushings that are too warm, excessive play in

moving parts, binding in moving parts, excessive or

abnormal wear in gears and chains, and rust accumulation

indicate a lack of lubrication. If these conditions are found

during regular inspection, the lubrication interval for the

faulty parts should be shortened.

Perform an oil analysis at regular intervals of each fluid used

in the crane to determine oil-change intervals. Oil sample kits

are provided in the Parts Box of current production cranes.

It is assumed that the maintenance intervals are cumulative,

that is, daily maintenance tasks will be performed together

with weekly tasks, daily and weekly tasks will be performed

together with monthly tasks, etc.

Intervals are based on engine hour meter or individual

component hours of operation readings, as required.

Individual component hours of operation can be viewed on

the display in the cab (see MLC300 Main Display Manual for

instructions).

WARNING

Personal Injury Hazard!

Personal injury can occur if the following safety

precautions are not taken before and after servicing

machinery:

• Stop the engine and wait until all moving parts have

completely stopped (if necessary, position any grease

fittings on moving parts at the access point and then

stop the engine).

• Attach a WARNING “out-of-order” sign to the engine

start control in the operator’s cab to warn all

personnel that the crane is being serviced.

• Do not operate the crane until all safety guards and

covers have been securely reinstalled and all

maintenance equipment has been removed.

CAUTION

Machinery Damage!

Before lengthening lubrication intervals, check that all

parts are receiving an adequate supply of clean lubricant.

Otherwise, parts will be damaged from a lack of

lubrication. Contact your Manitowoc dealer or Manitowoc

Crane Care Lattice Team for recommendations on

lengthening lubrication intervals.

Loading...

Loading...