Lubrication Guide MLC300

F2280-22

Published 07-21-21

NOTE 1 Lower the boom to horizontal when checking oil

level in Drums 1 and 6.

NOTE 2 Travel the crawlers so the centerline through the

plugs M16a and M16b is horizontal.

NOTE 3 Crawlers are greased manually only when the

crane does not have the optional crawler auto

lube system.

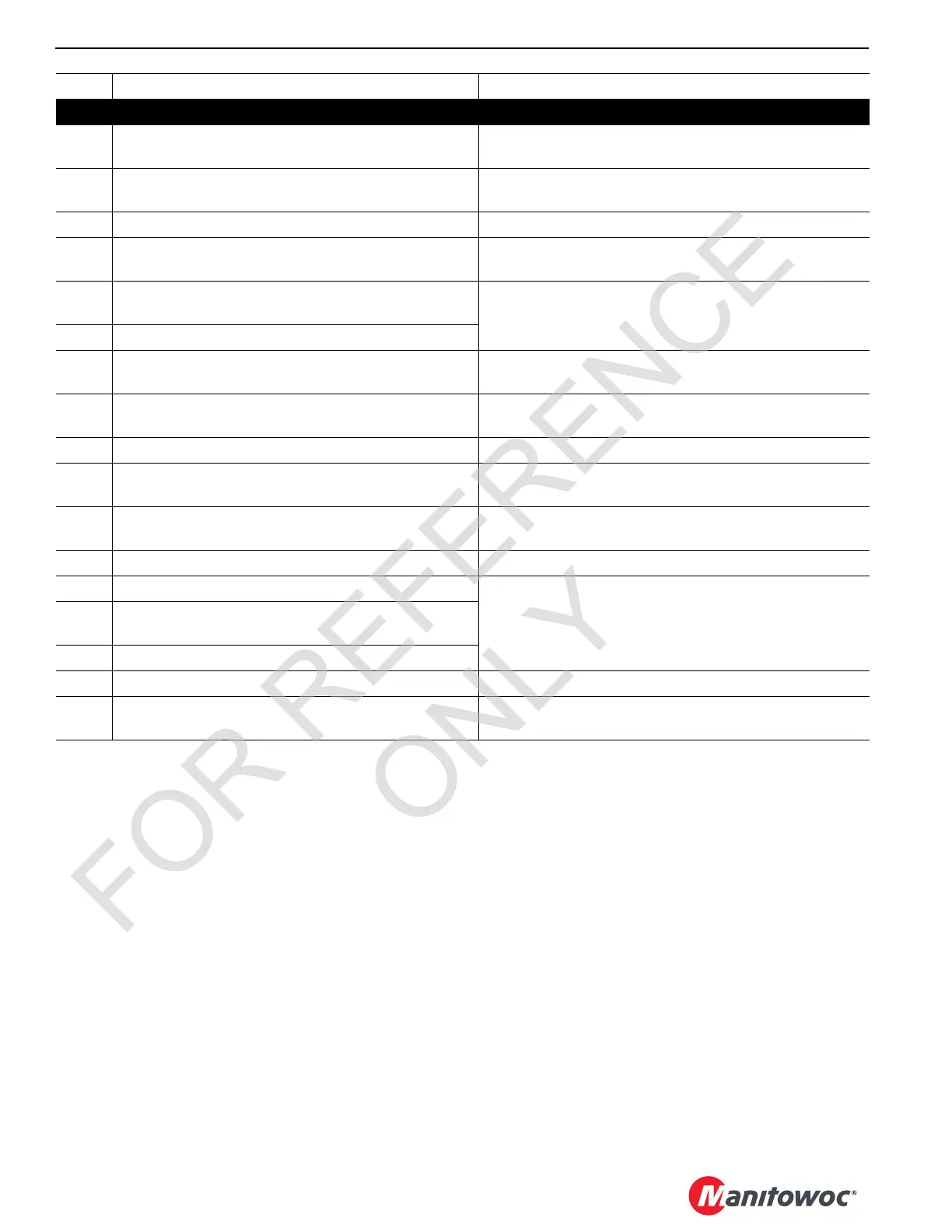

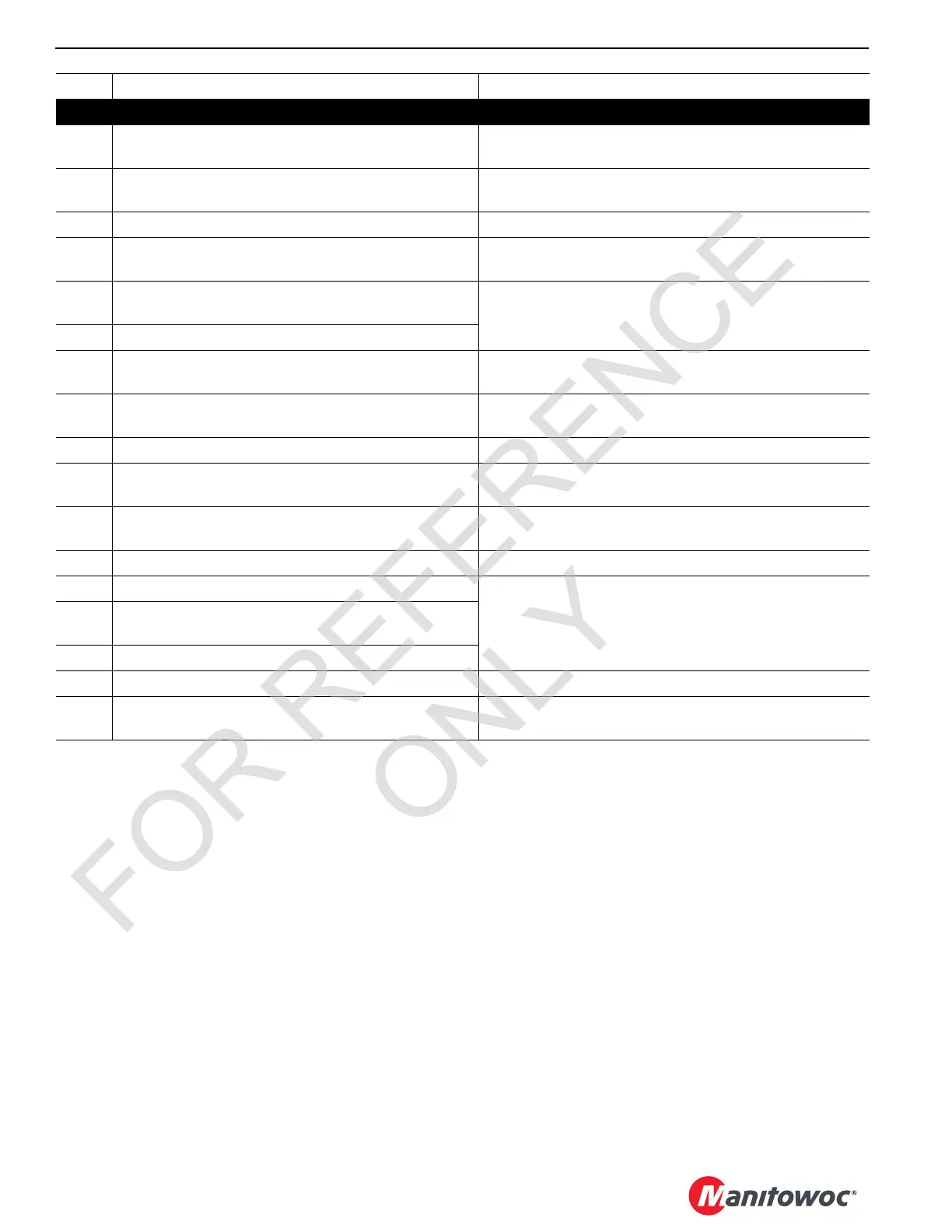

Item Description Required Service

Every 200 Hours of Operation or Monthly (whichever comes first)

M10 Swing Gear Box Sight Gauge (1 or 2 places) Check level. Should be at level indicated on decal next to

sight gauge

M11 Swing Gear Box Oil Fill and Breather Plug (1 or 2

places)

Fill each to proper level with gear oil.

M12 Drum Bearing (1 fitting, each drum) Grease.

M13 Drum Gear Box Sight Gauge (1 each drum) Check level. Should be at middle of sight gauge (see

NOTE 1).

M14 Drum Gear Box Oil Filling / Breather Plug (1 each

drum)

Fill each to proper level with gear oil.

M14a Drum Gear Box Optional Oil Fill Plug

M15 Engine Clutch Lever and Bearing (4 fittings - 1 top and

3 bottom)

Grease.

M16a Crawler Gearbox Oil Level Plug (1 each crawler)

(see NOTE 2)

Check level. Should be up to plug opening.

M16b Crawler Gearbox Oil Level Plug (1 each crawler) Fill each to proper level with gear oil.

M17 Dosing Module Filter (Tier 4F engine only) Inspect and replace as needed according to engine

manual.

M18 DEF Tank Filter (40 micron suction filtration) (Tier 4F

engine only)

Inspect and replace as needed according to engine

manual.

M19 Not Used

M20a Crawler Front Roller (1 fitting each crawler).

Grease (see NOTE 3).

M20b Crawler Intermediate Rollers (2 fittings, 15 places each

crawler)

M20c Top Roller (2 fittings, 2 places each crawler)

M21 Drum Motor Shaft Level Plug (each free fall drum) Check level. Should be up to plug opening.

M22 Drum Motor Shaft Oil Filling / Breather Plug (each free

fall drum)

Fill to proper level with gear oil.

Loading...

Loading...