Lubrication Guide MLC300

F2280-6

Published 07-21-21

APPROVED LUBRICANTS FOR NORMAL

OPERATION

NOTE For operation in arctic climates see “Approved

Lubricants for Arctic Operation” on page 8.

For operation in high temperature climates see

“

Approved Lubricants for High Temperature

Operation” on page 9.

Grease

Manitowoc Factory Fill

For the Manitowoc factory fill, see Table 1

.

Table 1 Grease

NOTE For all operation below -18°C (0°F) use arctic

grease specified in the Approved Lubricants for

Arctic Operation topic in this section.

Open Gear Oil

This type of oil requires heating or thinning for proper

application to gear teeth. Apply a light film of oil to each gear

tooth. Do not rely on gear rotation to distribute the oil.

Manitowoc Factory Fill

• CraneLUBE 375 NC (MCC Part No. 471178)

Gear Oil

Manitowoc Factory Fill

• CraneLUBE 75W-90 Synthetic (MCC Part No.

549515) for all gearboxes (drums, pump drive,

swing, VPC) except the crawler gearboxes and the

Drum 0 gearbox

• CraneLUBE 80W-140 Synthetic (MCC Part No.

A13890) for the crawler gearboxes

• CraneLUBE 80W-90 GL5 for the Drum 0 (rigging

winch) gear box (MCC Spec No. 6829003479)

For specific product recommendations, contact the

Manitowoc Crane Care Lattice Team.

Hydraulic Oil

Use a shear, stable anti-wear hydraulic oil that meets the

following viscosity targets:

• Cold Start Viscosity—<1600 cST

• Operating Temperature Viscosity—>12 cST (the

operating temperature is 38°C [100°F]

over

ambient temperature)

Manitowoc Factory Fill

• Phillips 66 Trans XP (MCC Spec No. 6829006444)

The factory fill hydraulic oil is a zinc-based multigrade

hydraulic oil that may not be compatible with certain ash-less

(metal-free) hydraulic oils. Consult with your oil supplier to

make sure the oil you select meets the above specification.

Filter new oil through a 10 micron portable filter.

The factory fill hydraulic oil is an all-weather hydraulic oil

suitable for use in ambient temperatures from -18°C to 43°C

(0°F to 110°F).

The factory fill hydraulic oil can cloud up (form wax crystals)

at ambient temperatures below -18°C (0°F). This condition

can result in damage to hydraulic components during start-

up.

When the expected ambient temperature will be below -18°C

(0°F), the hydraulic oil must be heated to at least -18°C (0°F)

prior to start-up. Tank heaters are available from Manitowoc.

The cloud point of oil selected must be equal to or less than

the expected ambient temperature.

Field Make-Up

Do not dilute the oil in the hydraulic tank with more than 25%

of another brand of oil. Dilution beyond the 25% maximum

could effect the crane’s operating performance at

certain temperatures.

If in doubt as to how much make-up oil has been added to

the tank on your crane, Manitowoc recommends that a

laboratory viscosity test be performed to determine if the oil

still meets the viscosity targets given above OR that the

system should be completely drained and refilled.

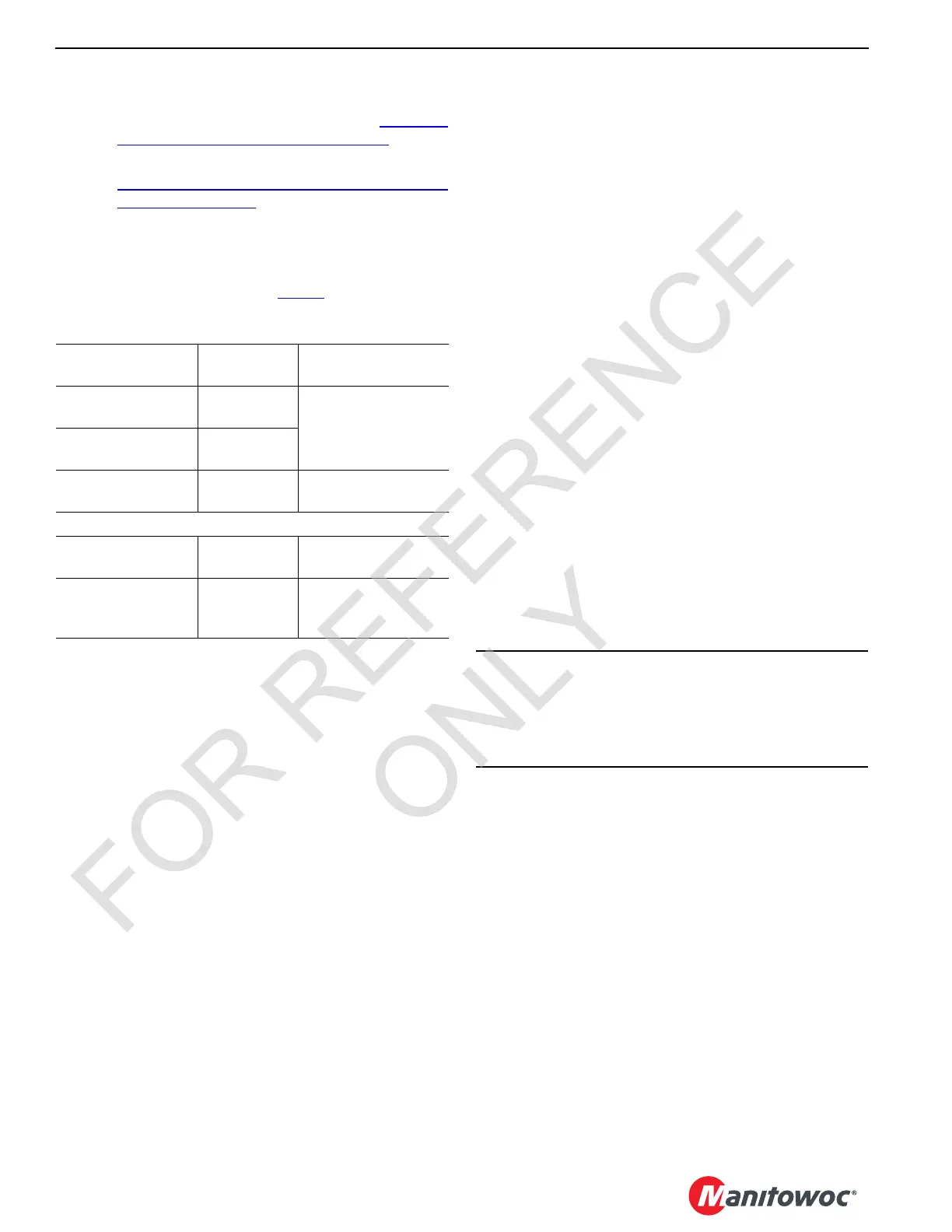

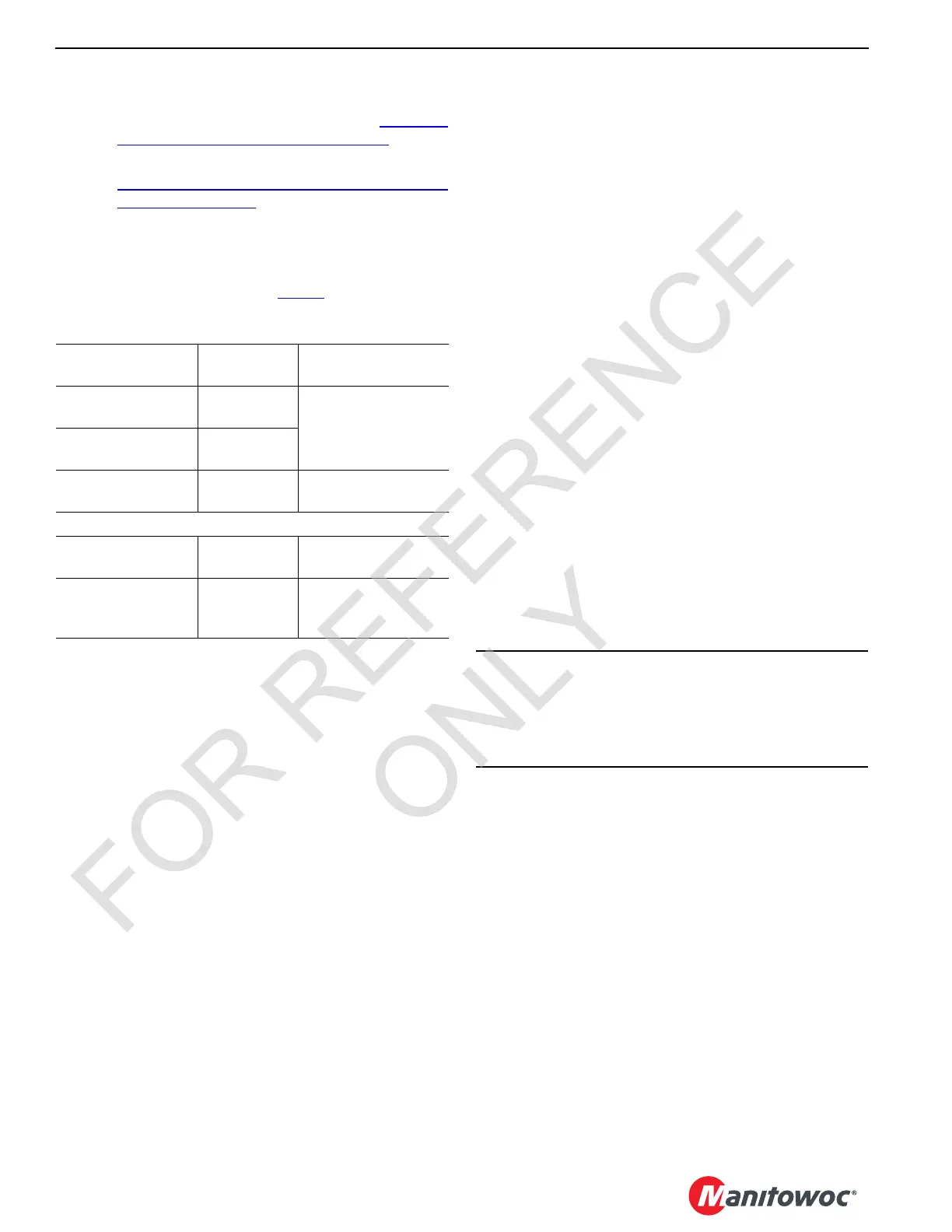

Turntable Bearing

and Crawlers

Temperature

Range

Application

CraneLUBE XHP

320 Mine

-40°C (-40°F)

and above

Automatic Lubrication

Systems

CraneLUBE XHP

321 Mine

4°C (40°F)

and above

CraneLUBE XHP

322 Mine

-18°C (0°F)

and above

Manual Lubrication

Other Grease

Points

Temperature

Range

Application

CraneLUBE E.P. # 2

(MCC Part No.

471197)

-18°C (0°F)

and above

Manual Lubrication

CAUTION

Hydraulic Pump Damage!

To prevent damage to hydraulic pumps, warm hydraulic

oil to at least 16°C (60°F) before operating the crane

functions.

Loading...

Loading...