Manitowoc F2280-3

Published 07-21-21

MLC300 Lubrication Guide

OVER-LUBRICATION

Over-lubrication is not only wasteful, but also harmful:

• Excess lubrication can work its way onto friction

surfaces and result in faulty operation.

• Oil or grease that drips onto walkways can cause

personnel to slip and be hurt.

• Too high an oil level can cause churning and foaming of

the oil and result in excessive heat and over-flow from

the reservoir.

• An extra shot of grease, if too stiff or under too much

pressure, can pop out a bearing seal.

LUBRICATION TIPS

Use the following tips during lubrication:

• Check all oil levels before start-up so the oil has had a

chance to run down from the reservoir walls and moving

parts.

• Avoid introducing dirt into reservoirs. Carefully clean the

area around dipsticks, level plugs, fill plugs, and

breathers before removing them.

• Replace level plugs, fill plugs, drain plugs, and breathers

snugly and wipe up any spillage.

• Keep oil and grease dispensers and containers tightly

closed and store in a dirt and moisture-free location.

• Clean grease fittings before and after applying grease.

• Apply grease until the bushing or bearing is purged so

dirt and water cannot enter. Wipe up excess grease.

• Protect the environment. Dispose of waste fluids, filters,

and batteries properly. See “

Environmental Protection”

on page 5.

WATER IN HYDRAULIC OIL

Prevent damage that can occur when water mixes with

hydraulic oil. Drain any accumulated water from the bottom

of the hydraulic tank at the start of each work day. Crack

open the drain valve at the bottom of the hydraulic tank.

Securely close the drain valve as soon as the water stops

draining and a steady stream of oil appears.

OIL CAN POINTS

Oil all pins not equipped with grease fittings with engine oil

every 40 hours of operation or once a week, whichever

comes first.

WIRE ROPE LUBRICATION

New wire rope is lubricated during manufacturing, but this

lubricant is only adequate for initial storage and the early

stages of operation. To prevent the damaging effects of

corrosion and to reduce wear, the wire rope must be

lubricated at regular intervals.

Contact your wire rope manufacturer/dealer for lubrication

recommendations. The lubrication interval and the type of

lubricant used depends on the type of wire rope, the severity

of duty, and the type of corrosive elements the wire ropes is

subjected to:

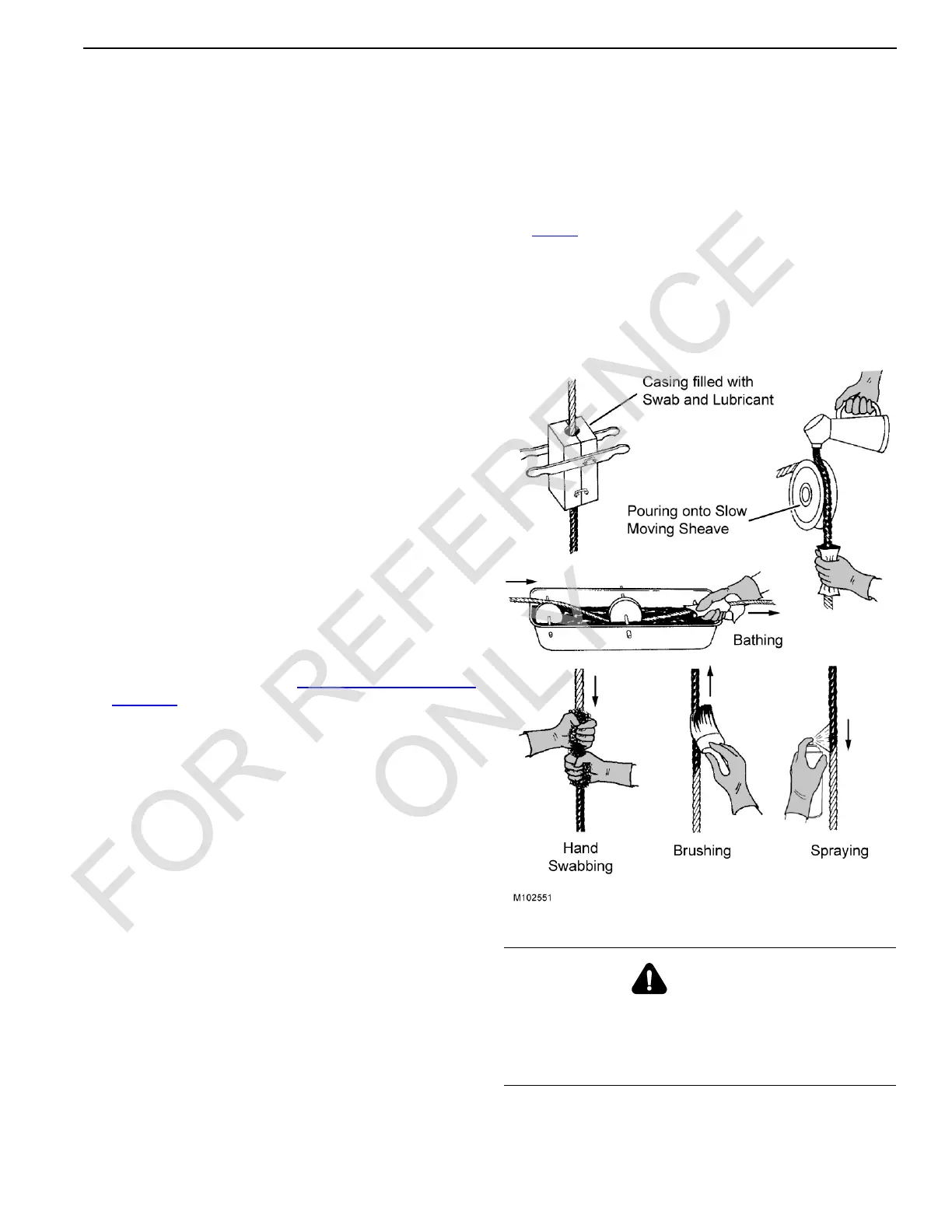

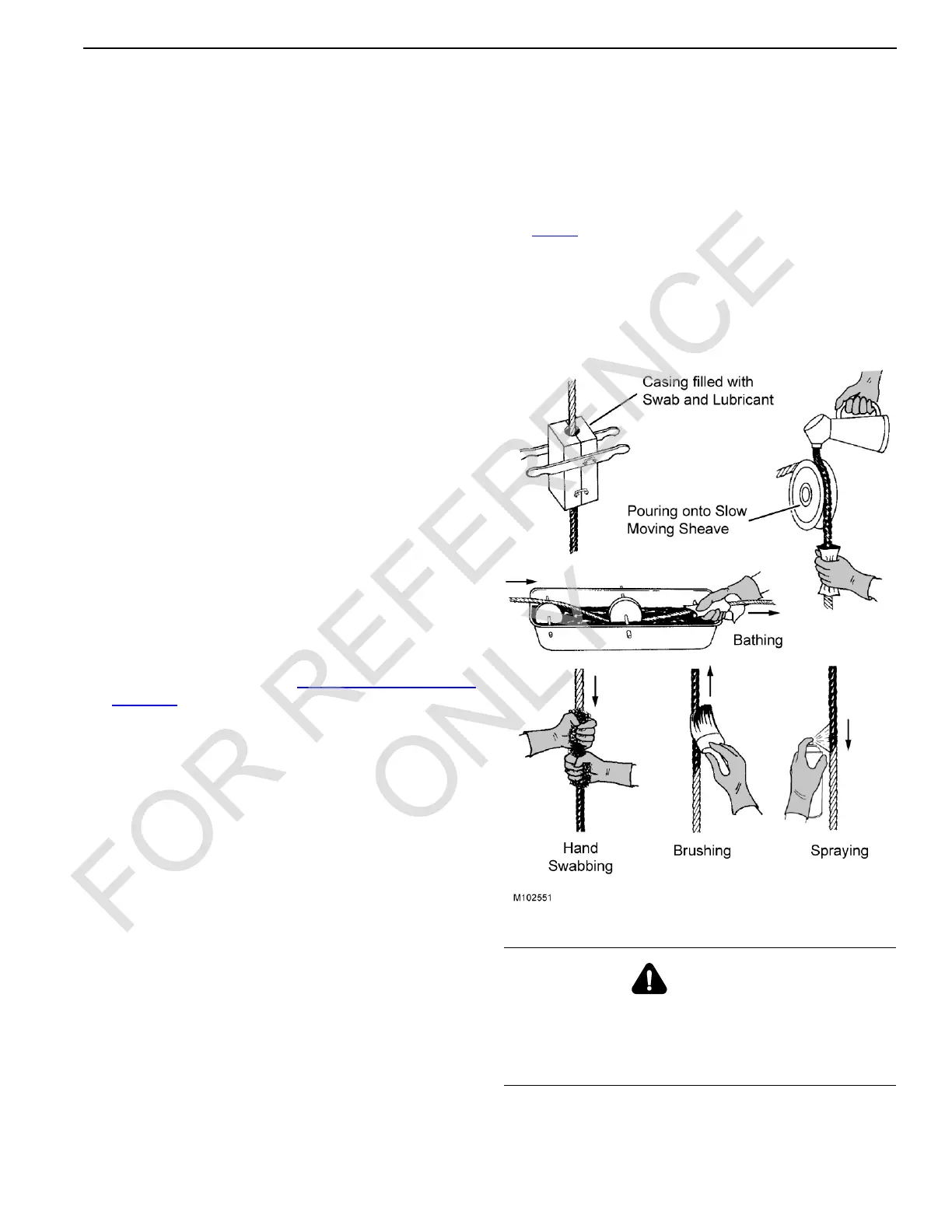

• The wire rope must be properly protected at all times.

• The lubricant must be fluid enough to fully penetrate the

strands and rope core. Use one of the methods shown in

Figure

to lubricate the wire rope.

• For maximum penetration, apply lubricant where the

wire rope “opens up” as it travels around a sheave or

winds onto a drum.

• The wire rope must be clean and dry before applying

lubricant. An air jet or wire brush may be used.

Do not use grease to lubricate wire rope. Grease will not

penetrate rope properly and will buildup in valleys

WARNING

Moving Rope Hazard!

Take every precaution to protect hands from injury when

rope is moving. Wear heavy gloves and move rope as

slowly as possible.

Loading...

Loading...