Lubrication Guide MLC300

F2280-4

Published 07-21-21

between wires and strands. This buildup will inhibit rope

inspection and could trap moisture in the rope’s interior.

A high-quality wire rope lubricant is available from the

Manitowoc Crane Care Lattice Team.

CYLINDER ROD LUBRICATION

General

The cylinder rods on Manitowoc cranes have a layer of

chrome plating on their surfaces to help protect them from

corrosion.

However, the chrome plating has cracks in its structure which

can allow moisture to corrode underlying steel. Depending

on ambient temperature and the frequency of cylinder

operation, the crane’s hydraulic oil may not penetrate these

cracks and protect the rods. Even if the cylinders are

operated on a regular basis, many cylinders have portions of

exposed rod even when the cylinders are fully retracted.

Exposed cylinder rods on cranes that are stored,

transported, or used in inclement environments (high

humidity, rain, snow, and salt air) are at a high risk of

corrosion.

Protecting Cylinder Rods

All exposed cylinder rods must be protected by applying a

thorough coat of cylinder-rod protectant available from

Manitowoc in 12 oz. aerosol cans—order part number

9999101803.

The cylinder-rod protectant contains solvents and lubricants

that penetrate metal pores, displace moisture, dissolve

existing corrosion, and then dry to a resilient waxy coating.

Cylinder operation and weather will remove the protectant

over time. Therefore, inspect all cylinder rods weekly and

reapply protectant to exposed rods.

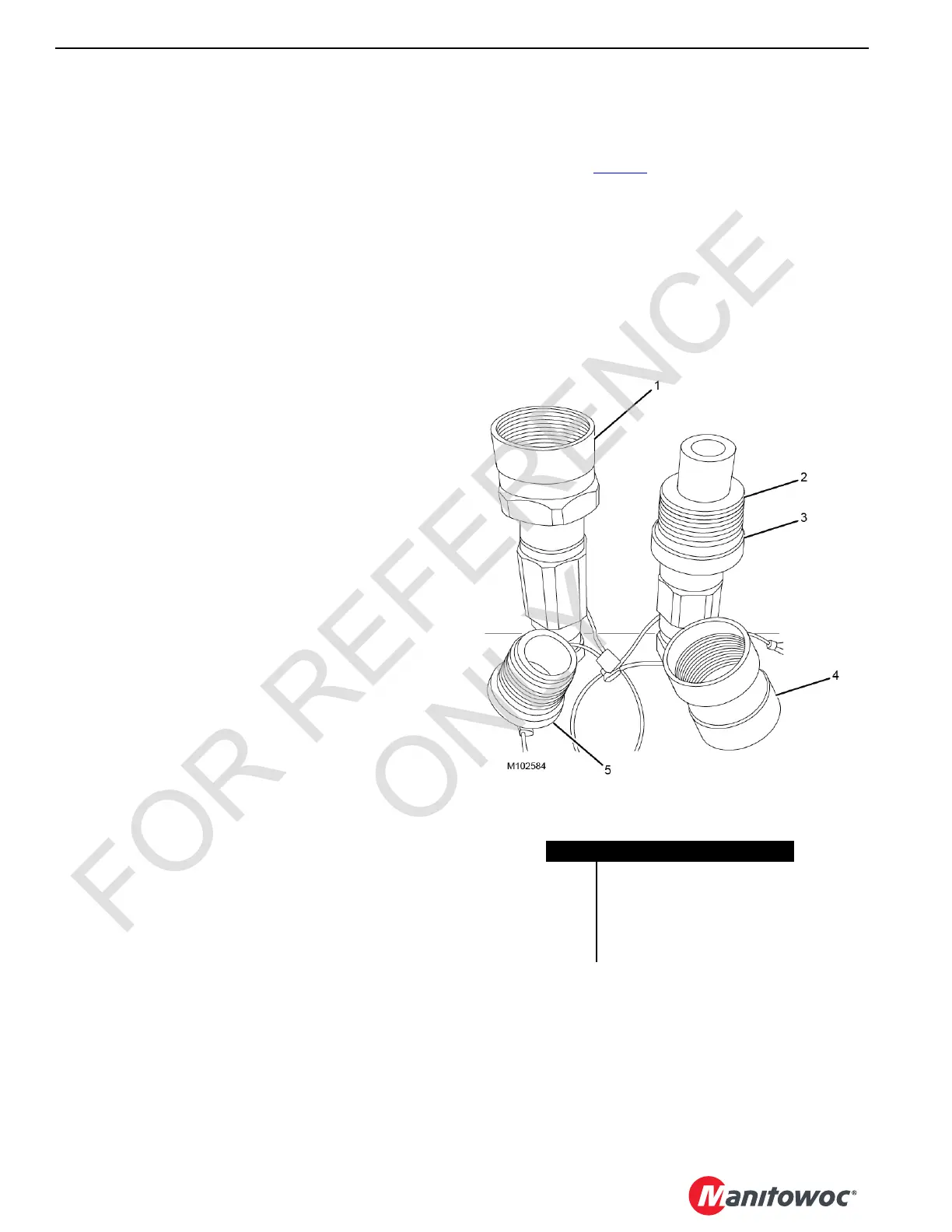

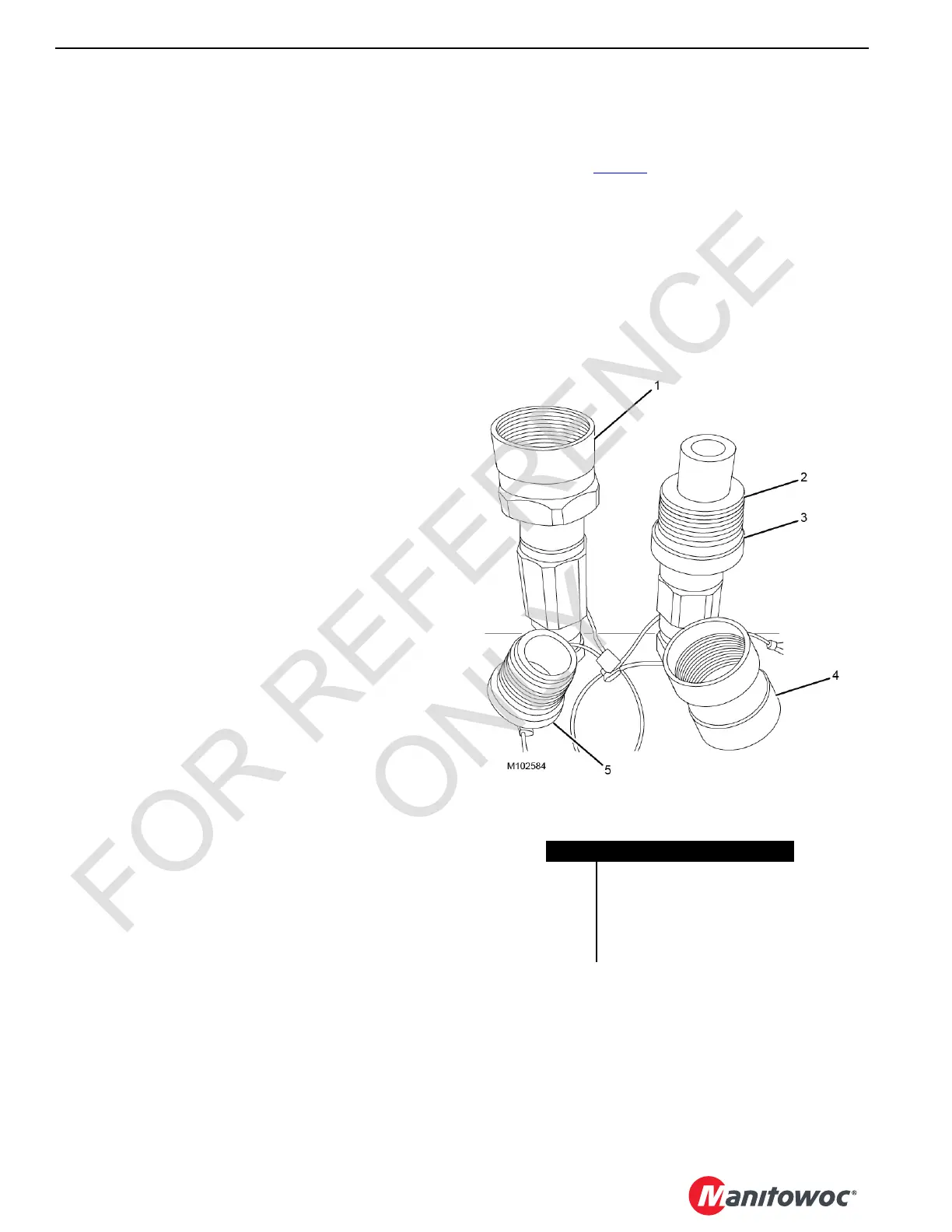

HYDRAULIC QUICK DISCONNECT

LUBRICATION

All hydraulic quick disconnects must be protected by

applying LPS-2 Aerosol Lubricant. Lubricant must be applied

while connecting and disconnecting the hydraulic quick

disconnects during crane assembly and disassembly.

1. All Quick Disconnects must be fully screwed together

until there is metal to metal contact during crane

assembly.

2. All plugs, regardless of location, must be fully screwed

together into their corresponding caps until there is

metal to metal contact during crane assembly.

Examples of locations of caps and plugs:

• hanging lanyards

• storage brackets

• job box

3. All Quick Disconnects must be fully screwed together

with their corresponding cap and plug until there is metal

to metal contact during crane disassembly.

The following threaded areas of the quick disconnects, caps,

and plugs must be lubricated during crane assembly and

disassembly (see Figure 3

):

• threaded surface of male quick disconnect

• threaded surface of female quick disconnect

• threaded surface of aluminum caps and plugs

• o-rings

NOTE If the crane is stored without operating for long

duration, the hydraulic quick disconnects, caps,

and plugs must be lubricated every 6 months.

FIGURE 3

Item Description

1 Female Quick Disconnect

2 Male Quick Disconnect

3 O-ring

4 Aluminum Cap

5 Aluminum Plug

Loading...

Loading...