Part Number 020002365 08/25/2015 11

Section 2 Installation

Location Requirements

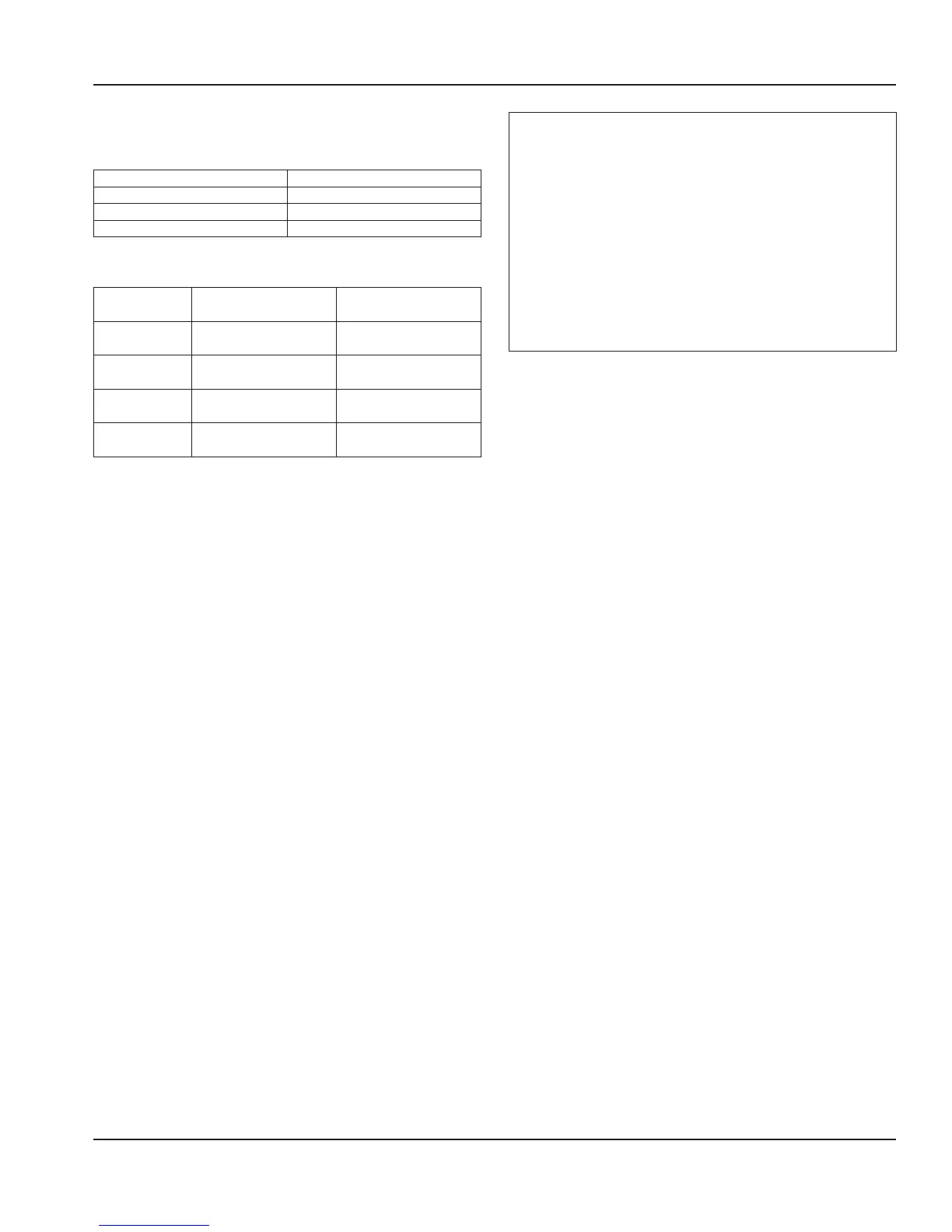

CLEARANCES

Control Side (Right) 18" (45.7 cm)

Tower Connection Side (Left) 12" (30.5 cm)

Back Side 6" (15.2 cm)

Ceiling 18" (45.7 cm)

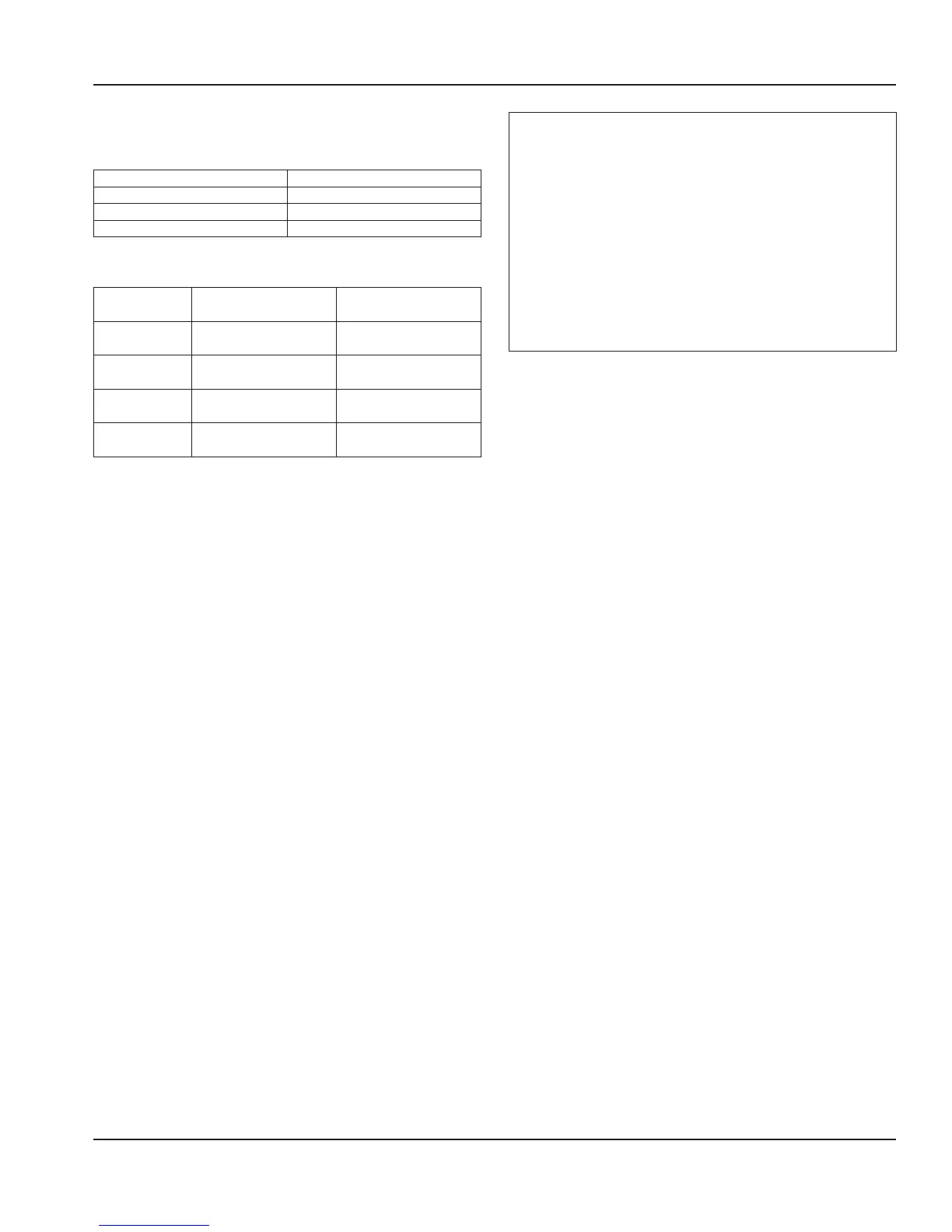

RATINGS

Model

Evaporator Rating at

20°F (-6.5°C)

Heat Rejection (Max.)

Model 42

Model 44

9,700 BTUH

2,340 kcal/hr

13,576 BTUH

3,685 kcal/hr

Model SC1000 9,700 BTUH

2,340 kcal/hr

13,576 BTUH

3,685 kcal/hr

Model 50 14,900 BTUH

3,310 kcal/hr

20,400 BTUH

4,285 kcal/hr

Model SC2000 14,900 BTUH

3,310 kcal/hr

20,400 BTUH

4,285 kcal/hr

Select a location for the refrigeration unit that meets

the requirements of the building plans, local codes, and

personnel. The unit must be positioned for free airflow as

well as for future service. The following requirements must

be met:

• 300 GPH (1135 LTR/hr) potable water supply (all models)

• Beverage quality CO

2

gas (bulk or bottled supply) with a

minimum 3/8" (0.96 cm) line

• One Bag-In-Box (BIB) container of each post mix syrup

flavor.

NOTE: Refer to nameplate on side of refrigeration unit for

voltage and amperage specifications. Make all electrical

connections at the junction box located at the top rear of

unit. Optional equipment may require additional power

supplies.

NOTE: Potable water connections to the equipment must

comply with local plumbing code requirements, particularly

the back-flow prevention requirements.

NOTE: Operating decibel level is above 70db.

n

Warning

Carbon Dioxide (CO

2

) displaces oxygen. Exposure to a

high concentration of CO

2

gas causes tremors, which

are followed rapidly by loss of consciousness and

suffocation. If a CO

2

gas leak is suspected, particularly

in a small area, immediately ventilate the area before

repairing the leak. CO

2

lines and pumps must not be

installed in an enclosed space. An enclosed space can

be a cooler or small room or closet. This may include

convenience stores with glass door self serve coolers. If

you suspect CO

2

may build up in an area, venting of the

BIB pumps and/or CO

2

monitors must be utilized.

KITCHEN EQUIPMENT INSTALLER REPRESENTATIVE

RESPONSIBILITIES

Prior to scheduling Multiplex Equipment installer, the

following steps listed below must be completed:

1. Usable floor sewer drain.

2. Refer to electrical requirement chart for your model.

3. Usable potable water.

4. CO

2

Gas (bulk or bottled supply); minimum 3/8" line.

5. One 5 gallon (19 L) container or Bag-In-Box container of

each post mix syrup flavor.

6. A 120 VAC, 3-wire, 1 Phase, 60 Hz dual wall receptacle

for optional electrical equipment (domestic only).

NOTE: Do not schedule the authorized Multiplex Equipment

Installer until all of the above have been completed. It will

only result in charge-backs to you for the unnecessary trips.

REQUIREMENTS FOR POST MIX REFRIGERATION UNITS

• Conduit can be run through floor or ceiling chase.

• 60°F (15.6°C) minimum and 100.4°F (38°C) maximum

operating ambient conditions.

• For indoor installation only.

• Syrup supply can be located on stand or adjacent to

refrigeration unit.

Loading...

Loading...