8-8 3-29-2018 Control # 610-00

MAINTENANCE CHECKLIST NBT40-1 SERIES OPERATOR MANUAL

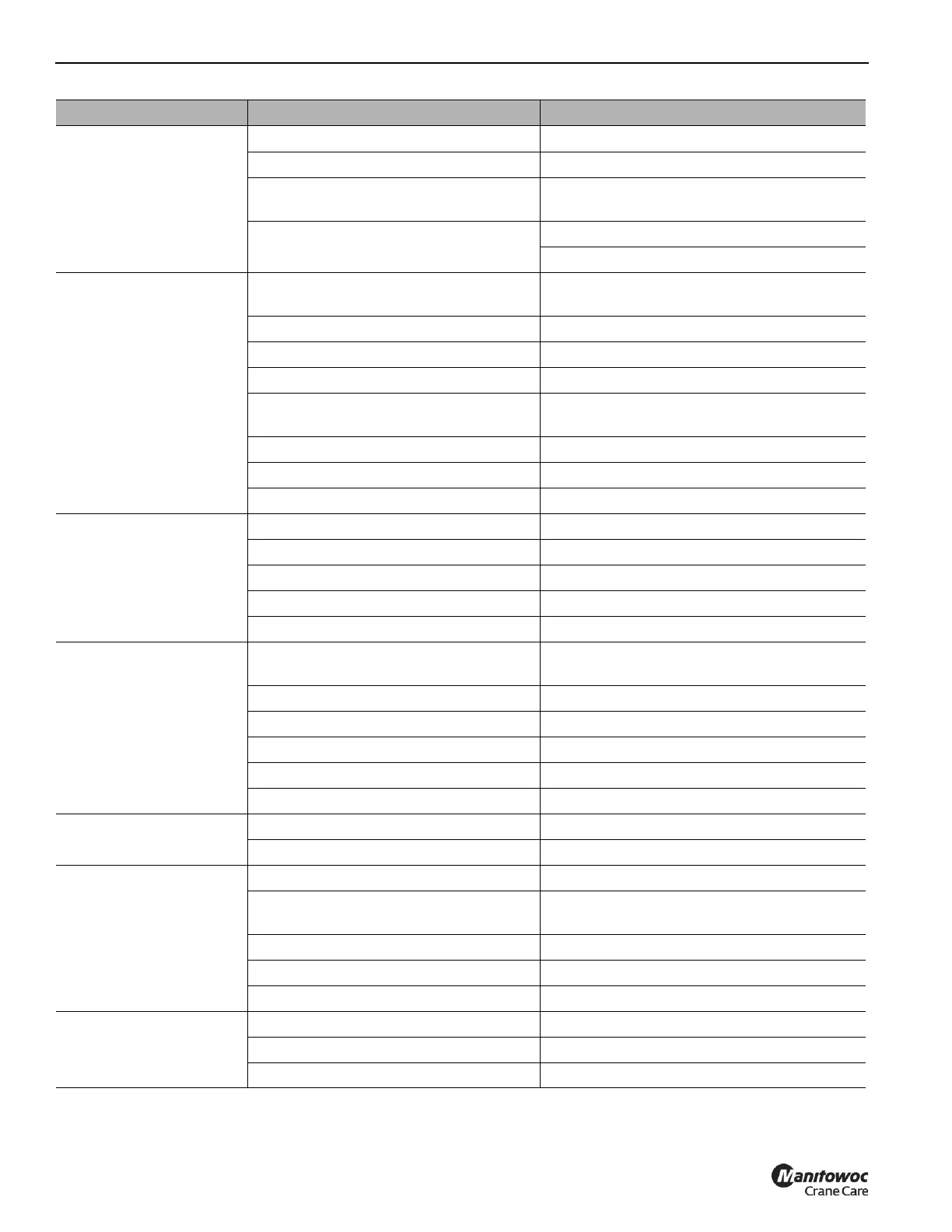

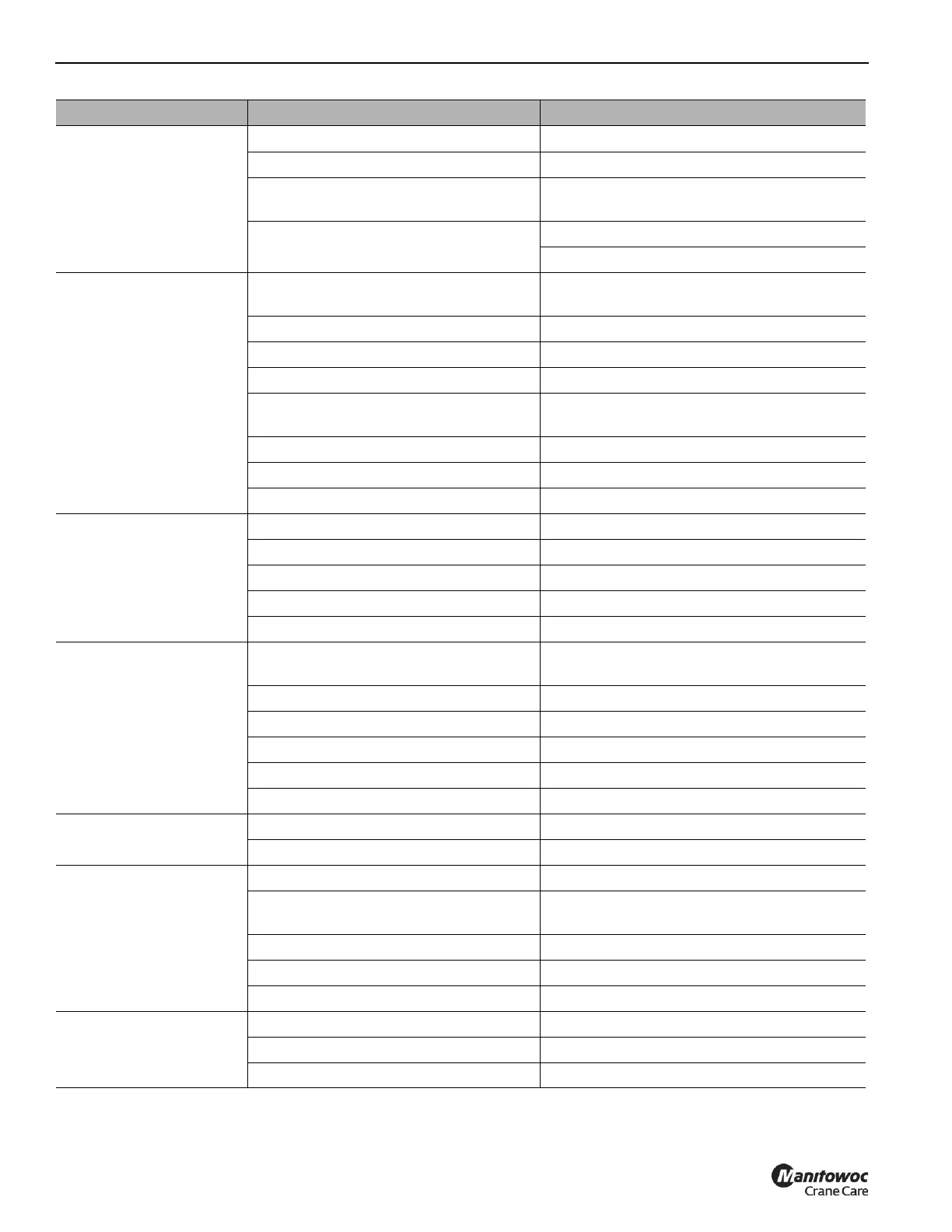

Swing will not turn

(Standard System)

Turn circuit relief valves sticking. Clean and check circuit pressure.

Turntable bearing drag. Lubricate thoroughly as rotating boom.

Brake not releasing properly.

Check brake pilot pressure. Clean pilot line or

adjust motor counterbalance valves.

Swing speed adjustment set too low.

Adjust or clean brake for proper release.

Adjust valve on turn motor.

Excessive pump noise

during operation.

Excessive pump speed.

Adjust foot throttle or check for too high PTO

ratio.

Low oil temperature. Allow unit to warm up.

Low hydraulic oil supply. Check and fill.

Suction line kinked, collapsed or blocked. Clear blockage.

Hydraulic oil too thick.

Warm oil or use oil more applicable to

environment.

Relief valve chattering. Dirt in relief valve or damaged relief.

Hydraulic tubing vibration. Check for loose tubing.

Tank breather plugged. Clean breather.

Cylinders drift

Not getting oil to cylinders. Clean and replace as required.

Worn or damaged piston seals. Replace as required.

Air in hydraulic oil. Cycle equipment cylinder to remove air.

Loose holding valve. Tighten valve.

Dirt in holding or check valve. Clean valve.

Hoist will not lift or hold

load.

Load too heavy.

Check load and change to applicable multipart

reeving.

Relief valve setting too low. Check and adjust if required.

Motor worn excessively. Replace motor.

Counterbalance valve defective or leaking. Clean and replace as necessary.

Anti-two-block system defective. Repair anti-two-block system.

Brake worn out. Repair or replace brake.

Hoist gearbox heats.

Gearbox grease low. Check and fill as required.

Duty cycle too high. Reduce cycle time or speed of Hoist.

Boom chatters during

extension/retraction or

doesn't proportion properly.

Boom sections need lubrication. Grease boom.

Wear pads not shimmed correctly.

Re-shim as described in boom assembly

section.

Worn wear pads. Replace pads.

Extension cables out of adjustment. Readjust cables and tension properly.

Extend or retract cables broken. Disassemble, inspect, and replace cables.

Boom will not extend.

Proportioning cables not attached. Reconnect, replace and/or adjust cables.

Anti-two-block system shut down. Lower hook, and extend load.

Defective anti-two-block system Repair ATB if defective.

Condition Possible Cause Possible Solution

Loading...

Loading...