National Crane 3-29-2018 Control # 610-00 4-19

NBT40-1 SERIES OPERATOR MANUAL OPERATING CONTROLS - CRANE

This system is comprised of several sensors and modules

located throughout the machine:

1. Outrigger string potentiometers are used in the standard

outrigger monitoring system (OMS).

2. An aerial lift interlock module is located inside the torsion

box near the passenger side outrigger controllers (See

Figure 4-15.)

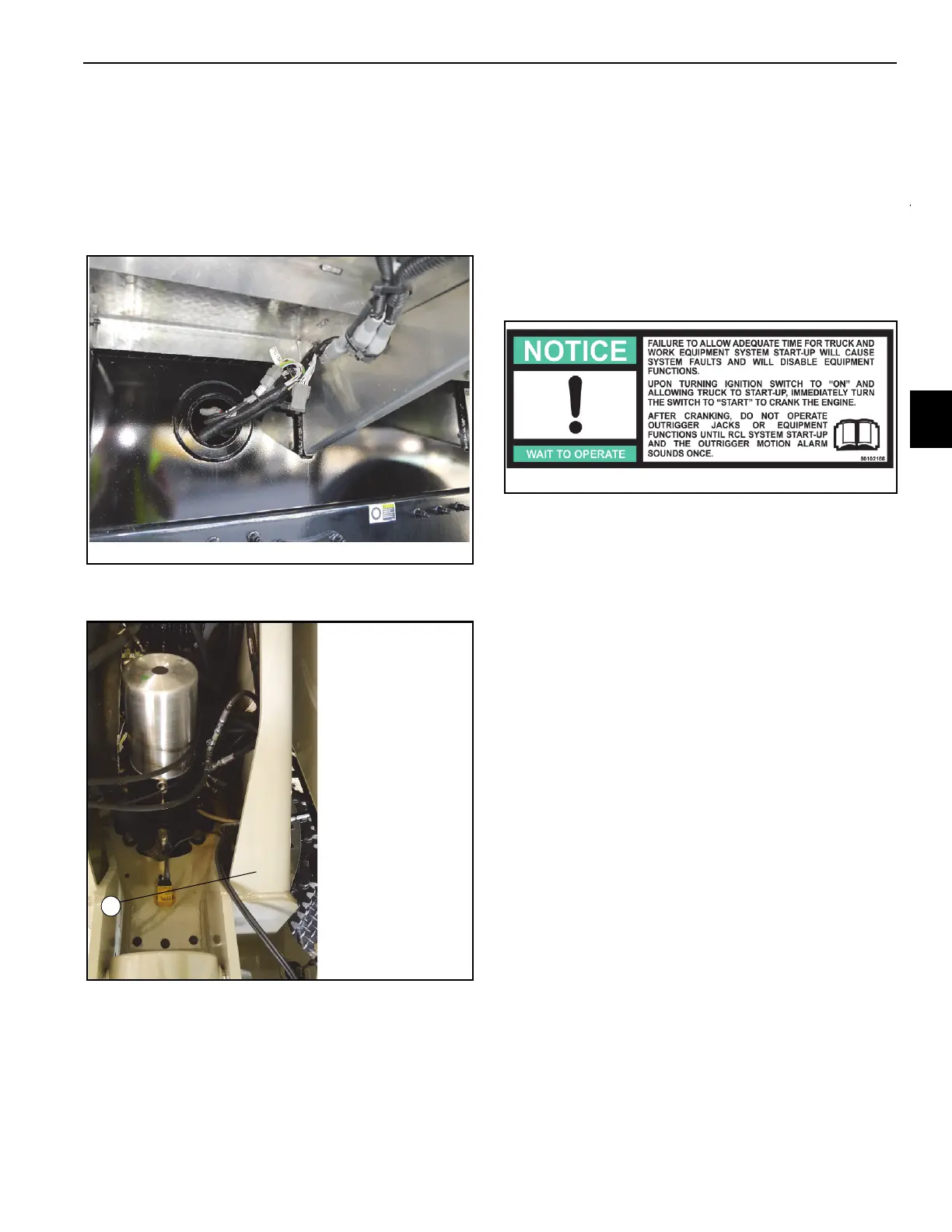

3. A 3-axis inclinometer is located in the crane turret (See

Figure 4-16).

4. Slew position sensor located internal to the electrical slip

ring (See Figure 4-16).

5. Truck chassis parking brake switch located on the truck

chassis (J1939 CANbus interface)

6. Outrigger motion alarm (OMA) located at the rear of the

machine.

7. Boom angle sensor located internal to the RCL system

length and angle cable reel on left side of boom.

Startup

Upon turning the operator cab keyswitch to the ignition

position, the outrigger jack monitoring system begins to

sense the configuration of the machine. The truck engine

must be started within approximately 30 seconds of ignition

position in order for all sensors to be powered up and

communicating with the aerial lift interlock module

Figure 4-17.

After engine is running, the outrigger functions must not be

operated until the RCL system has powered up and is ready

to be configured. The outrigger motion alarm will sound once

to indicate the system is operational. During this time, all

boom functions are disabled until the outriggers are properly

setup within specifications.

Outrigger Setup

The outriggers can be setup and leveled per operating

instructions, and the RCL can be configured to match the

actual configuration of the machine. The outrigger jack

monitoring system will not allow operation of any crane

functions until:

1. Outrigger jacks are extended

2. Boom is in the boom rest

3. Outriggers are leveled.

If operation is allowed, the outrigger motion alarm will

activate and sound two low pitch tones followed by a single

higher tone indicating the boom functions are permissible for

operation.

During Operation

Once boom functions are permitted, the boom functions

operate normally as per operating instructions. The outrigger

jack monitoring system monitors the real-time status of the

level sensor during operation and allows full range of

operation. If the sensor indicates that the machine is not

level according to the specifications, the outrigger motion

alarm (OMA) will sound indicating an out of level condition.

All boom functions will remain operational when alarm

Loading...

Loading...