11

Fig. 44

Fig. 45

Fig. 46

Coin

Battery

26

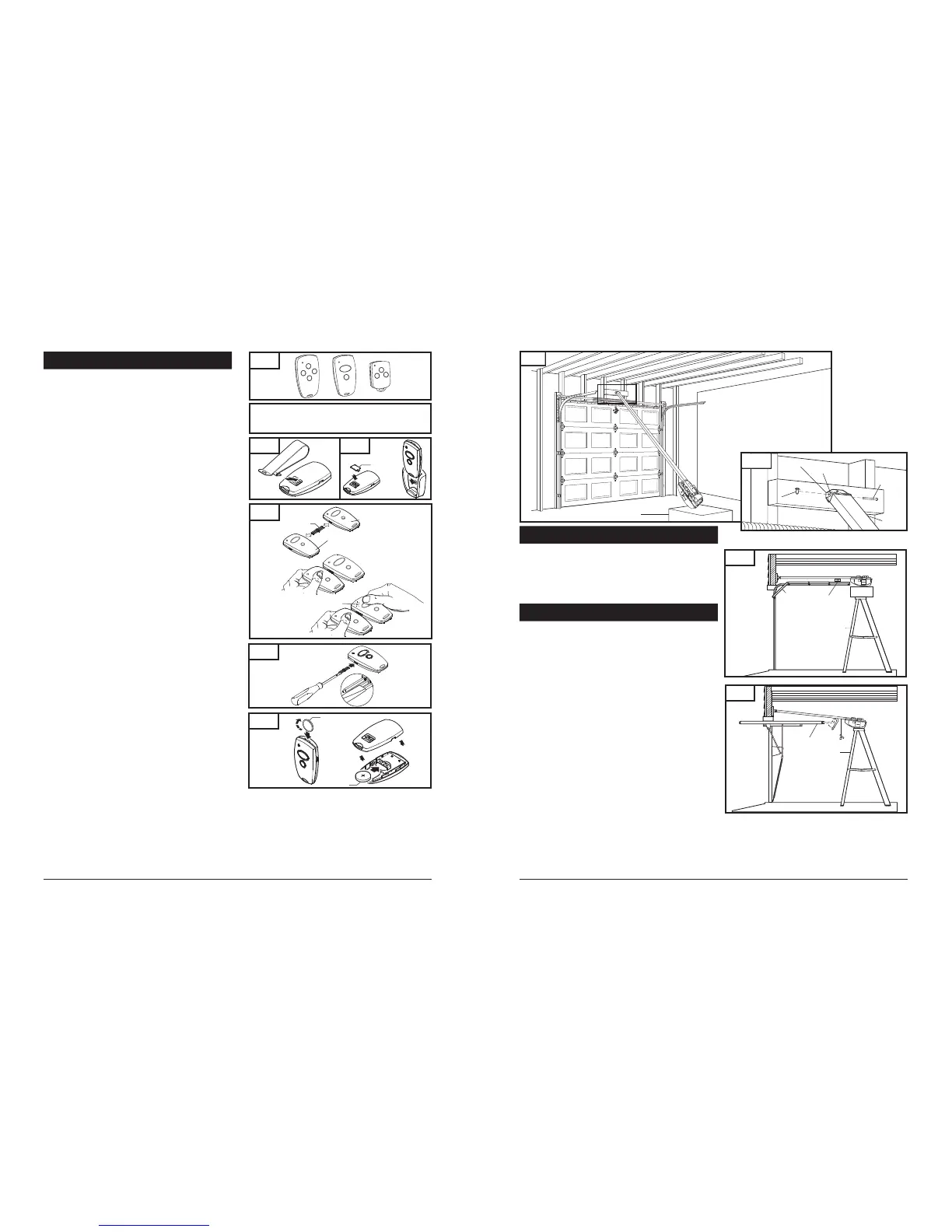

8-5. ATTACH RAIL TO HEADER BRACKET

Support operator head slightly off the floor.

Lift the opposite end of the rail up to the header bracket.

Position rail end-stop within the openings in the header

bracket. Insert header clevis pin ( 1/4” dia.) through header

bracket and rail end-stop, then attach cotter ring to end

of pin. (See Fig. 19A)

8-6. POSITION OPERATOR FOR MOUNTING

Fig. 20

Once rail is attached to header bracket, support operator on ladder,

or use the assistance of another person to support operator high

enough so door can open without hitting the rail.

A. SECTIONAL DOORS AND ONE-PIECE DOORS WITH

TRACK:

Open garage door to fully opened position, and place a 2x4

laid flat between the door and the rail. See Fig.20. This provides

an easy method of ensuring the correct mounting height of

the opener.

B. ONE-PIECE DOORS WITHOUT TRACK:

Disconnect trolley by pulling down on emergency release knob.

Move trolley toward opener head.

Open door all the way so that it is parallel to the floor, or slightly

tilted toward the front of the garage. DOOR SHOULD NOT BE

TILTED TOWARD THE BACK OF GARAGE.

Position operator so that top of operator head is level with top

of opened door.

To check for correct mounting height, temporarily position

curved door arm as if connecting to door bracket. See Fig. 21.

The long side of the arm should be parallel to the floor when

door is fully opened. Raise or lower powerhead so that arm

will be parallel to floor.

Temporarily support head at this height, and prepare to mount

the operator to ceiling.

Door

2x4 Laid Flat

Stepladder

Door

Stepladder

Fig. 41

Fig. 42

Fig. 43

Visor Clip

Visor

Compartment

Cover

FCC Certified: This device complies with Part 15 of the FCC rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Changes or modifications not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

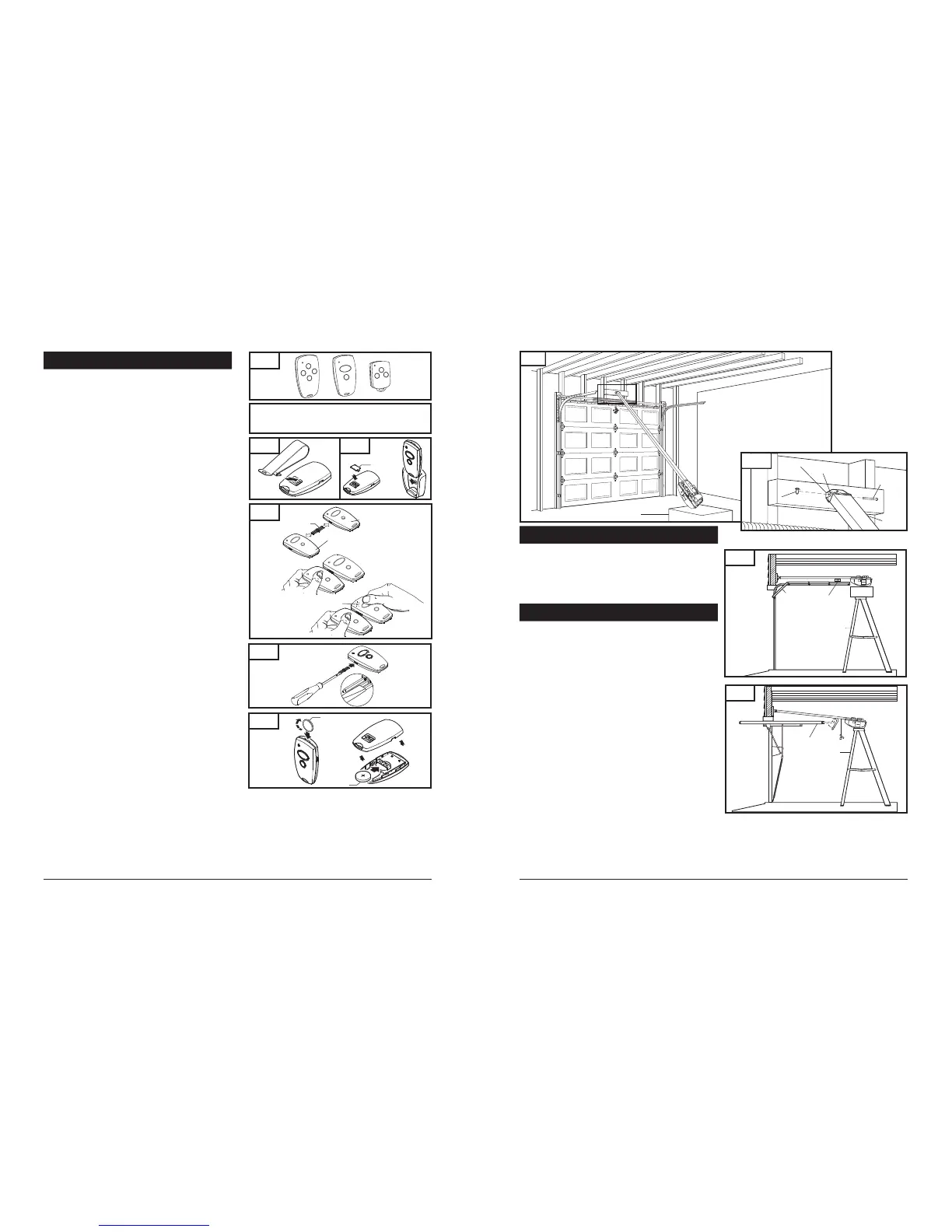

10. TRANSMITTERS

TRANSMITTERS (Fig. 41):

A family of state-of-the-art transmitters, each transmitter is custom

encoded with installed battery. Offered in two styles to suit your

personal preference.

Mini (2-or 4-channel)

Micro (3-channel) with keyring attachment.

TRANSMITTER MOUNTING:

The transmitters can be conveniently mounted inside your

car using the visor clip or on the wall using the mounting plate.

Visor Clip (Fig. 42)

Snap visor clip into transmitter.

Affix assembly to visor.

NOTE: If you do not need the visor clip, install the visor

compartment cover.

Mounting Plate (Fig. 43)

Secure the mounting plate to area of preference using screw

and anchor.

Snap the visor compartment cover.

Slide the transmitter into the mounting plate, which will hold

it firmly in place.

MULTIPLE TRANSMITTERS (Fig. 44):

Each transmitter comes factory programmed with random codes.

2-channel transmitters have 2 different random codes, one per

button, 3-channel transmitters have 3 different random codes and

4-channel transmitters have 4 different random codes, one per

button. Transmitters that are purchased separately as accessories

have random codes that must be changed in order to match the

code of the “active” transmitter, which you are already using. Below

are instructions for transferring an active code from a button on one

transmitter to a button of your choice on another transmitter.

Connect the transmitter with active code to the new

transmitter using the programming connector. (Fig 44)

Press and hold the selected channel button on the transmitter

with the active code.

Press and hold the respective channel button on the new

transmitter. The light in the transmitter initially starts

blinking and then illuminates continuously after 1-2 sec.

Code transfer is completed.

Programming connector can be removed and both

transmitters can now be used to operate the same opener.

NOTE: For multi-button transmitters, be sure to carry out this

procedure for all the buttons you desire to use.

CHANGING THE CODE (Fig. 45):

The transmitter factory preset code can be changed as follows:

Insert the programming connector into transmitter terminal.

Short one of the outer pins of the programming connector

with the middle pin.

Press and hold the respective channel button. The light will

blink rapidly for approximately 5 sec. Release the button after

the light illuminates continuously. Code will change in

approximately 2 seconds.

Remove the programming connector.

Once the transmitter code is changed, the operator must be

recoded with the new transmitter code as described on the

initial system set up page 19.

NOTE: For multi-button transmitters, be sure to carry out this

procedure for all the buttons you desire to use.

BATTERY REPLACEMENT (Fig. 46):

Open the transmitter by using small coin.

Insert a 3V battery (type CR2032) as shown.

Close the transmitter.

NOTE: Replace batteries with same type only.

Fig. 21

Fig. 19

Operator Box

Header Bracket

Rail End-Stop

Cotter Ring

1/4 x 3-1/4"

Clevis Pin

Rail

Fig. 19A

Transmitter with

active Code

New Transmitter

Programming

Connector

Light blinks

Loading...

Loading...