22

15

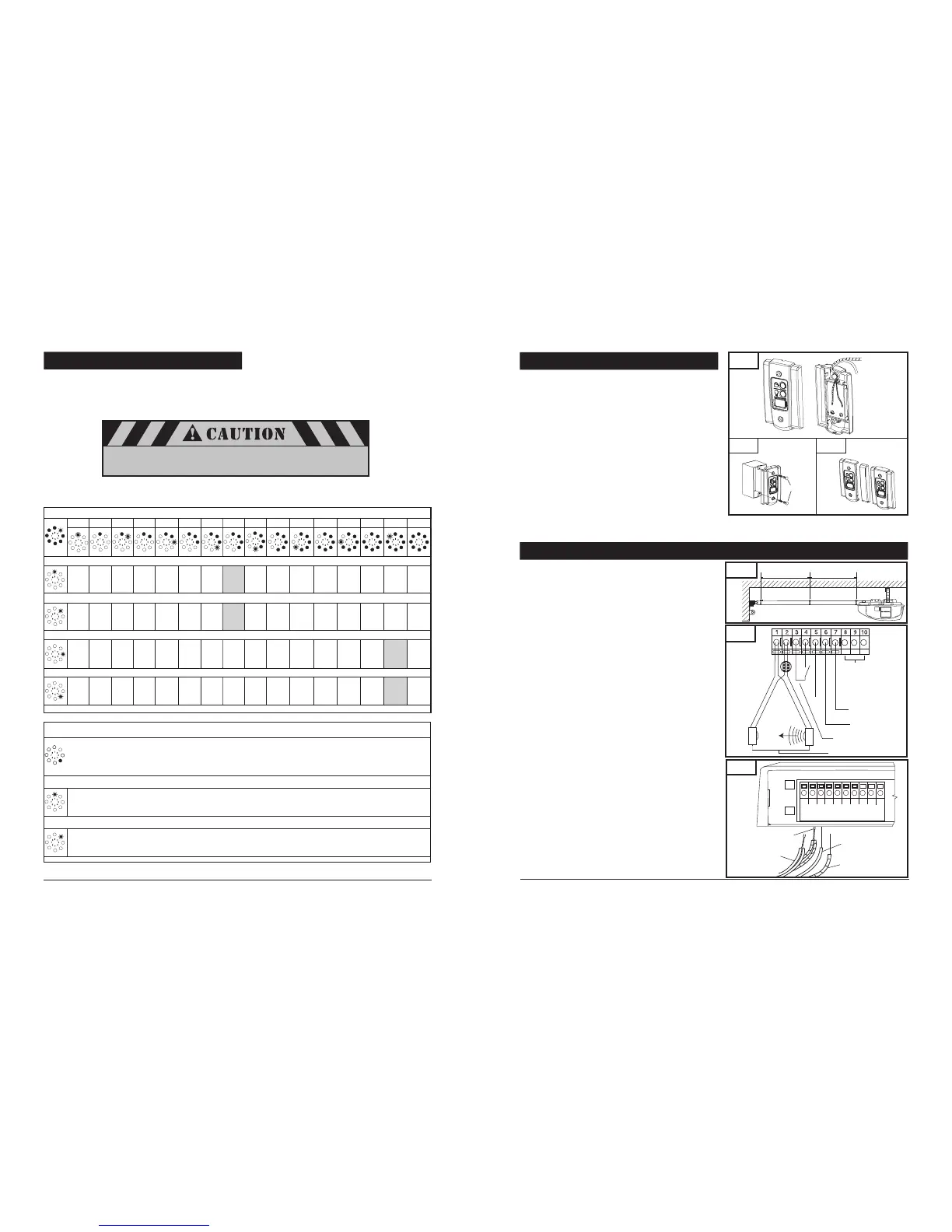

8-17. ADVANCED SETTINGS (cont’d)

Level 2 – Opener settings

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Menu 1: “OPEN” position operator (system) operating force (scale from 1 to 16)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Menu 2: “CLOSED” position operator (system) operating force (scale from 1 to 16)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Menu 3: “OPEN” position operator sensitivity (sensitivity scale from 1 to 16)

OFF 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Menu 4: “CLOSE” position operator sensitivity (sensitivity scale from 1 to 16)

OFF 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

The higher the sensitivity setting in menu 3 and 4, the higher the

operator force capabilities or less sensitive operation.

NOTE: Menus 5-7 are disabled

Press “+” or “-” button to scroll or navigate through menus.

Level 2: Functions overview

Menu 1: Impulse

Level 4 – Transmitter code programming

Not available

Menu 2: Intermediate position

LED 7 flashes slowly -> use transmitter button other than those designated for garage doors -> LED 7 flashes quickly

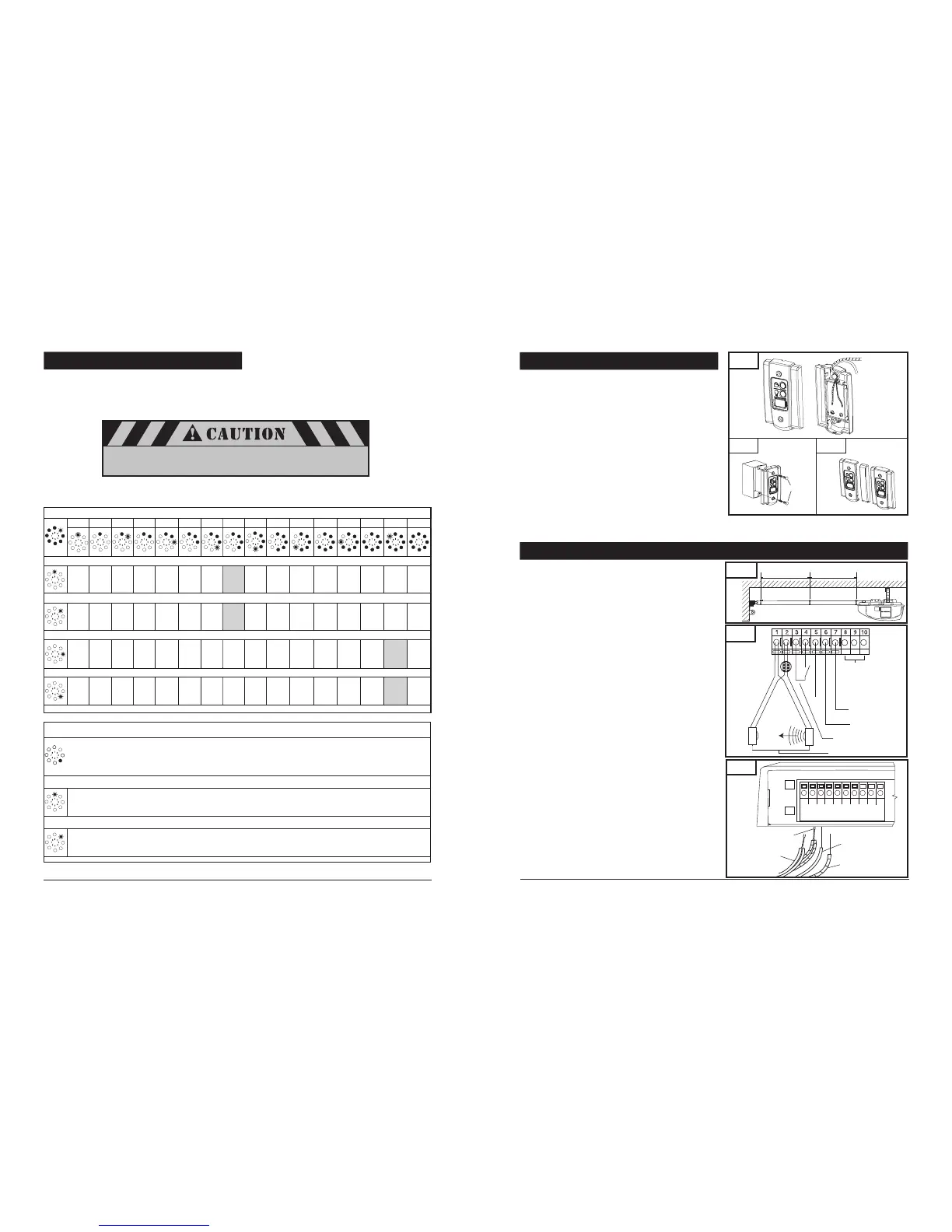

8-11. INSTALL WALL CONTROL PANEL

The control panel must be mounted inside the garage within sight

of the garage door, clear of all moving garage door parts or any

associated parts - and at least 5 feet above the floor to prevent the

use of these controls by children. The device should only be used

when the door is in clear sight of the user and the door area is free

of people or any obstructions.

Attach 2-conductor wire to the screw terminal on back of

control panel. See Fig. 31 (Back). White wire attaches to

terminal #3 screw, white wire with color stripes attaches to

terminal #4 screw.

Position wall control panel onto wall in desired location.

Mark hole location on wall.

Drill 1/16” pilot holes into wall.

Insert and tighten screws to secure control panel to wall.

Make sure wiring is routed out from behind control through

one of the cutouts to avoid pinching the wires.

If mounting to drywall instead of wood, drill 3/16” pilot holes and

use anchors provided. If mounting to electrical box that is prewired

for this purpose, mount directly to box with proper screws provided.

See Fig. 31A.

8-12. CONNECTING THE SAFETY SENSORS AND WALL CONTROL TO OPERATOR

Fig. 32A

24V

Common

(Ground)

Relay

T

R

Wall Control

Photo Eye Sensor System

Not Available

Fig. 32

1/2

1/2

Class 2

Supply 24 Volts

1 2 3 4 5 6 7 8 9 10

Fig. 32B

To Terminal 1

To Terminal 2

To Terminal 4

To Terminal 3

Run wires from the wall control panel along the wall and ceiling

to the operator quick-connect terminals, locate on the rear.

Use the staples to secure wiring to wall, joists and ceiling. Do

not pinch wiring. Drive staples with only enough force to hold

wiring in place. Refer to Fig. 9 on p.7 for an example of typical

wiring routing, and Fig. 32A for terminal assignment.

Insert white single wire from wall control into quick-connect

terminal #3 and single color striped wire into quick-connect

terminal #4.

NOTE:

Individual wall control stations can be combined into one

solid panel.

Detach right side panel from one of the wall controls. (Fig.31B)

Attach wiring to each wall control.

Combine single panels into one block.

Follow the same steps as above to mount additional wall control

panels and wire connections, only connect one wall control

per operator.

Run photo eye system wires along the wall and the top of the

rail assembly to the operator. Use the three wire holders to

secure wires. See Fig. 32.

Insert the stripped end of the white wire combination

firmly into quick-connect terminal #1 by pushing the

wires directly in the terminal hole. If the wires are difficult

to insert, a screwdriver may be used to depress the

terminal "tab" while inserting the wires. To remove wires,

depress the tab again and pull wires out.

Repeat procedure for the stripe wires (white/black stripe),

insert them into quick-connect terminal #2.

NOTE: If wires are difficult to insert, a screwdriver may be

used to depress the quick-connect terminal “tab” while

inserting the wires. To remove wires, depress tab again and

pull wires out.

Fig. 31

Screw caps

4

3

To Terminal #4 Screw

To Terminal #3 Screw

Fig. 31B

Fig. 31A

Loading...

Loading...