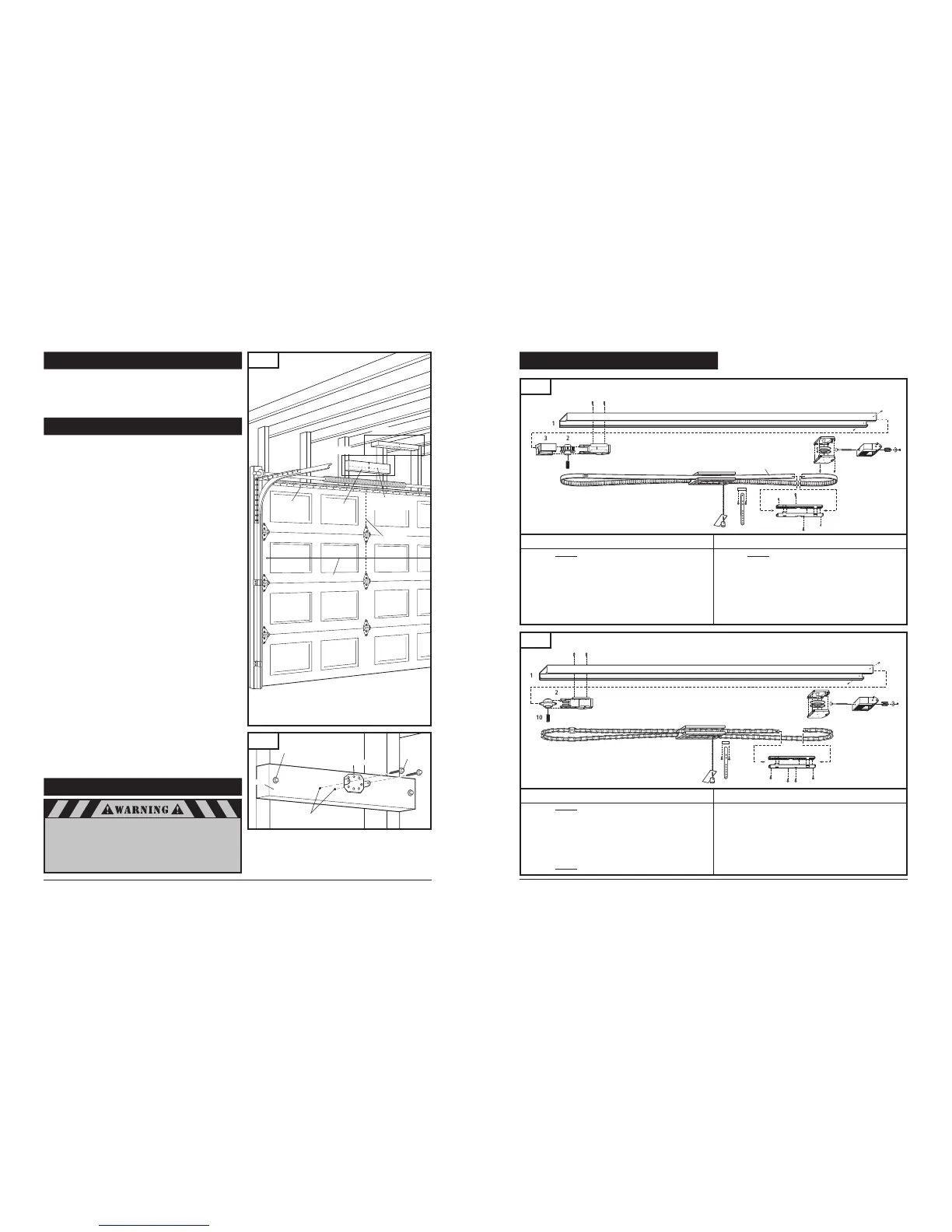

8. INSTALLATION STEPS

8-1. MEASURE AND MARK DOOR AREA

Horizontal

Reinforcement

Bracket

Header

Horizontal Line for

Header Bracket

Height

Door Width

See Fig. 12

See Fig. 11

Vertical

Center Line

Identify a sound structural support on header wall above garage

door for header bracket mounting. See Fig. 11. If appropriate

header does not exist, replace or install a new support using a 2x4

or 2x6 board. Fasten it securely using lag screws (not provided) to

structural supports of garage.

Before starting your installation, the door and the header above

the door must be measured and marked. This way, the appropri

-

ate brackets can be mounted at the correct locations avoiding

installation and operating difficulties later.

MARK VERTICAL CENTER LINE:

Measure door width, then locate the center point (Fig.10).

Mark a vertical line on the upper half of your door, on the top

edge of your door, and on the header, through the center

point.

MEASURE DOOR’S HIGHEST TRAVEL POINT:

(Review Figs. on p. 5 for details)

Open door to its highest travel point and measure from the

garage floor to the top of door.

Write down this distance.

FOR SECTIONAL DOORS AND ONE-PIECE DOORS WITH

HORIZONTAL TRACK:

Add 1-1/4" to the door travel height (measured above).

FOR ONE-PIECE DOORS WITHOUT TRACK:

Add 3-3/4" to the door travel height (measured above).

MARK HORIZONTAL LINE FOR HEADER BRACKET

LOCATION:

Close door and measure the required distance (determined

above) from the garage floor to the header.

Mark a horizontal line, intersecting the vertical center line, on

header. This is the position at which the bottom of the header

bracket should be installed.

In case of minimal clearance above the door, the header

bracket may be mounted to the ceiling. In this case, extend

the vertical center line onto the ceiling, and mark a horizontal

line on the ceiling no further than 4" from the header wall.

The header bracket should be mounted no farther than this

distance from the header wall.

8

Fig. 10

29

Header

Lag Screw for Header installation

if necessary (not provided)

Header Bracket

5/16 x 1-3/4"

Lag Screw

Pilot Holes

Fig. 11

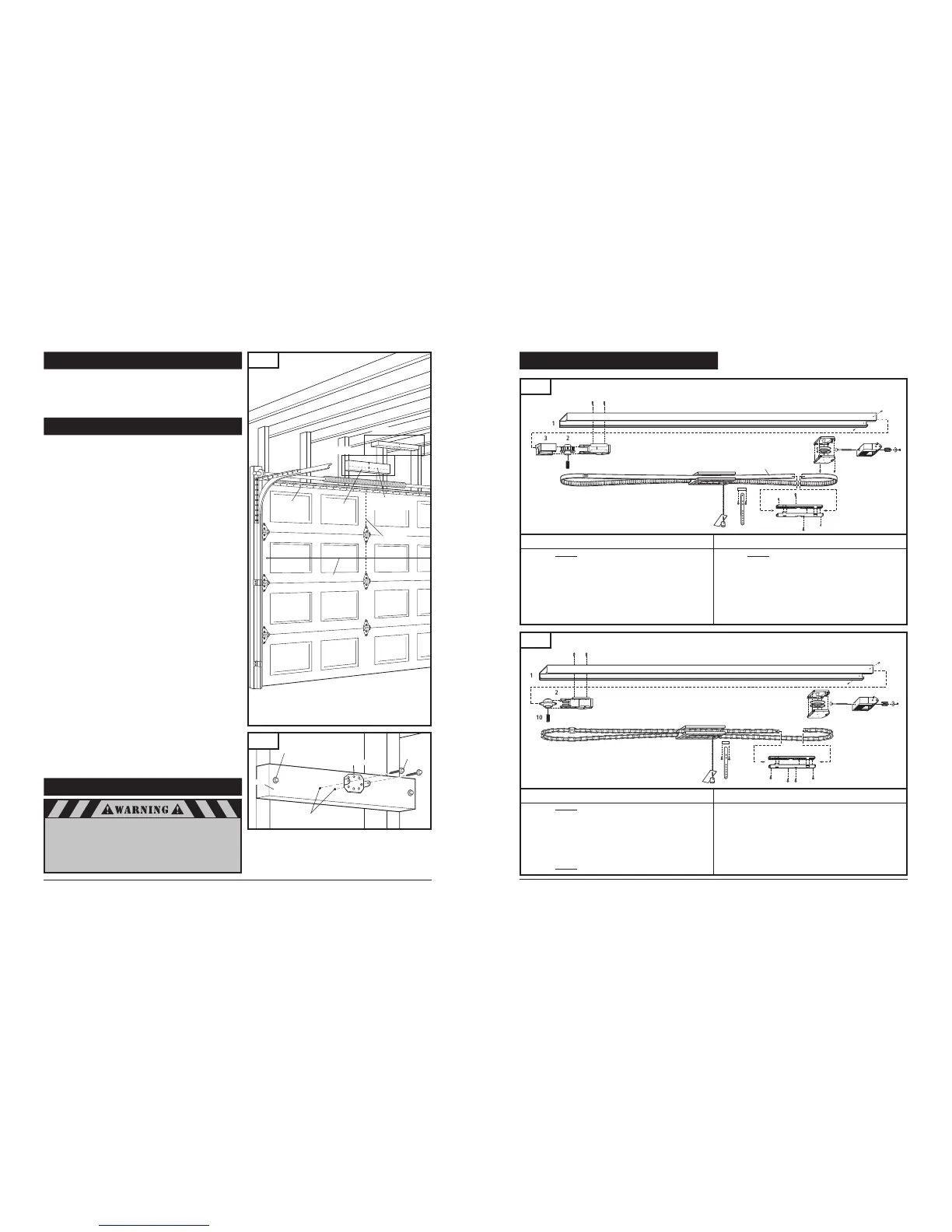

17. RAIL ASSEMBLY PARTS

Fig. 52

Belt Rail Assembly

Model#: ML-807B (7' Door) ML-808B (8' Door) ML-810B (10' Door)

Item Part # Description

1. Rail

2. 8030337 Sprocket holder assembly

3. 8008709 Belt guide

4. 8030432 Roller holder with tension bolt assembly

5. 8008503 Rail end-stop

6. 8030196 Belt connector

Item Part # Description

7. Belt with position tab

8. 8030177 Trolley assembly (7’ Door)

8030178 Trolley assembly (8’ & 10’ Door)

9. 8008708 Pin

10. 8030735 Straight door arm

11. 8007412 Shaft adapter

Fig. 53

Item Part # Description

1. Rail

2. 8030339 Sprocket holder assembly

3. 8030432 Roller holder with tension bolt assembly

4. 8008503 Rail end-stop

5. 8030234 Chain connector

6. Chain with position tab

Item Part # Description

7. 8030177 Trolley assembly (7’ door)

8030178 Trolley assembly (8’ & 10’ Door)

8. 8008708 Pin

9. 8030735 Straight door arm

10. 8007412 Shaft adapter

Chain Rail Assembly

Model#: ML-807C (7' Door) ML-808C (8' Door) ML-810C (10' Door)

Power Head End

Power Head End

8-2. INSTALL HEADER BRACKET

If the header bracket is not rigidly fastened to a sound

structural support on the header wall or ceiling, the

safety reverse system may not work and could cause

serious injury or death. DO NOT move or adjust springs

or garage door hardware, as these parts are under

extreme tension and could cause injury or death.

6

Loading...

Loading...