9

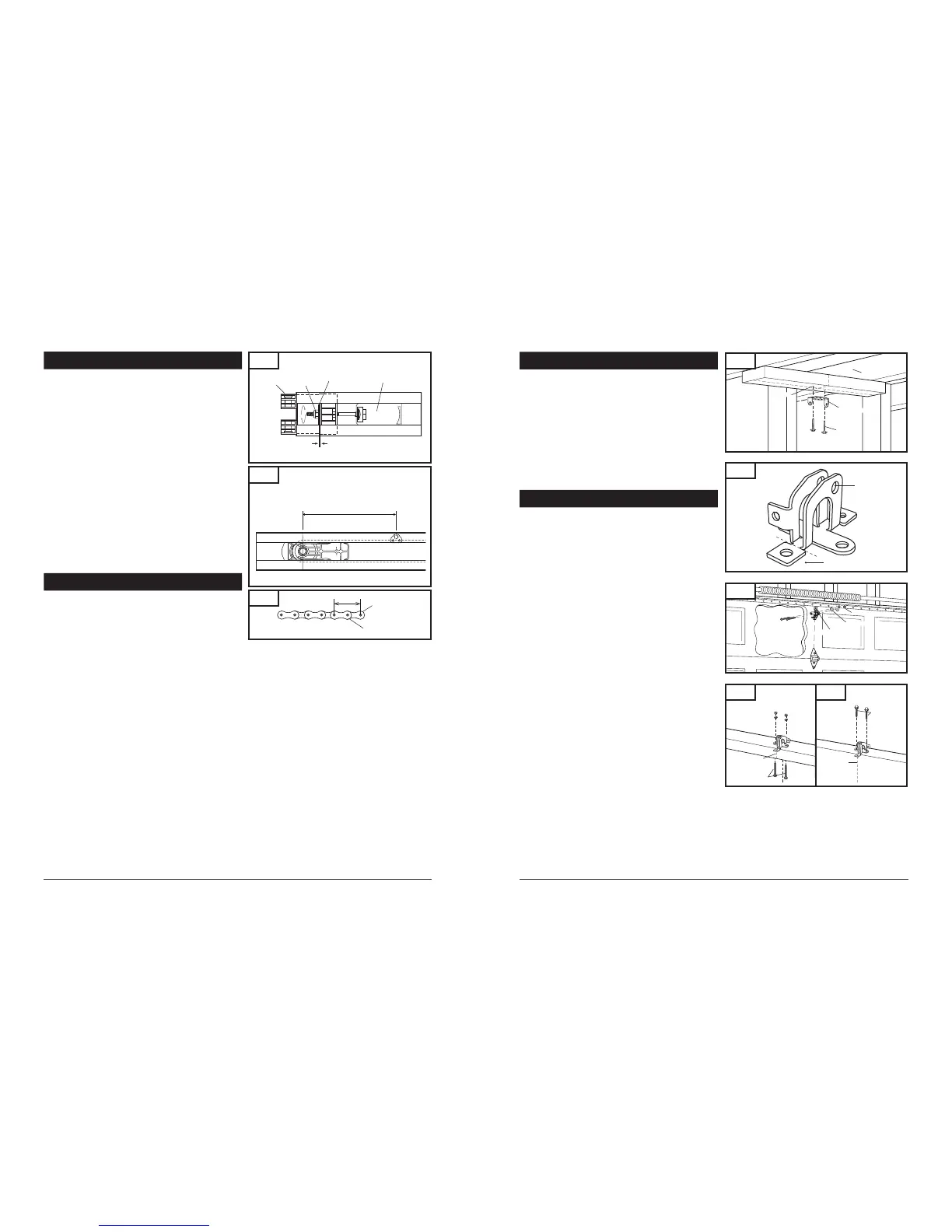

15. TENSION ADJUSTMENT

16. RAIL LENGTH ADJUSTMENT

Fig. 50

Proper Tension Adjustment

Your preassembled rail comes with the tension adjusted to factory

specifications. There should be no need for further adjustment.

However, if exposed or subjected to unusually harsh operating

conditions, the tension may need to be readjusted during the life

of the opener.

CHECK PROPER TENSION (Fig. 50):

Release trolley from belt or chain, then examine the setting of

the tension adjustment at the header end of the rail.

Proper tension is set when the tension nut is tightened just

enough so that the washer will be spaced approximately 1mm

or 3/64" from the stationary rail end-stop arch.

If the gap between the washer and the rail end-stop arch is too

big or too small, the tension needs to be adjusted.

ADJUST THE TENSION:

To increase the tension and tighten the belt or chain, turn the

tension nut clockwise with 7/16” wrench until the washer is

spaced properly from the rail end-stop arch. See Fig. 50.

Once the washer is spaced correctly, any additional tightening

will overtighten the belt or chain and may cause damage to the

system.

To loosen the tension, turn nut counterclockwise.

Reattach trolley.

Fig. 50A

960 mm (37-3/4")

Fig. 51

1"

FOR PROFESSIONAL INSTALLERS ONLY

If your particular installation calls for a shorter rail than the

standard length provided, it is possible to shorten the rail.

NOTE:

Shortening rail too much may result in door travel

length reduction and door not opening fully. This depends

on door size and configuration. Carefully plan all such

modifications before proceeding. THIS PROCEDURE SHOULD

BE PERFORMED ONLY BY A PROFESSIONAL INSTALLER FULLY

FAMILIAR WITH THIS TYPE OF OPENER SYSTEM.

TO SHORTEN BELT RAIL LENGTH:

Loosen belt tension as much as possible.

Remove screws from sprocket holder and rail end-stop.

Slide belt and all rail parts out of rail from header end. See rail

exploded view, Fig. 52 on p. 29, for disassembly details.

Measure and cut off excess rail from header end.

Using rail end-stop as a guide, mark and drill two 3/16" holes

on rail sides for rail end-stop screws.

Disassemble connector to expose free ends of belt.

Using the same measurement as the excess rail length, cut the

same amount off BOTH free ends of the belt.

Reassemble belt connector, and slide all rail parts into rail from

header end according to original assembly (Fig. 50 and

Fig. 50A).

Tension belt properly (Fig. 50).

Check rail for proper assembly and operation by manually

moving trolley from end to end and back to position per

Fig. 50A, with trolley connected to belt.

TO SHORTEN CHAIN RIAL LENGTH:

Loosen chain tension as much as possible.

Remove screws from sprocket holder and rail end-stop.

Slide chain and all rail parts out of rail from header end.

See rail exploded view, Fig. 53 on p. 29, for disassembly

details.

Measure and cut off excess rail from header end by 1”

increment only.

Using rail end-stop as a guide, mark and drill two 3/16"

holes on rail sides for rail end-stop screws.

Disassemble connector to expose free ends of chain.

Using the same measurement as the excess rail length,

remove the same amount off chain links and chain straps

from BOTH free ends of the chain (Fig. 51).

Reassemble two piece connector and slide chain and all

rail parts into rail from header end according to original

assembly (Fig. 50 and Fig. 50A).

Tension chain properly (Fig. 50).

Check rail for proper assembly and operation by manually

moving trolley from end to end and back to position per

Fig. 50A, with trolley connected to chain.

28

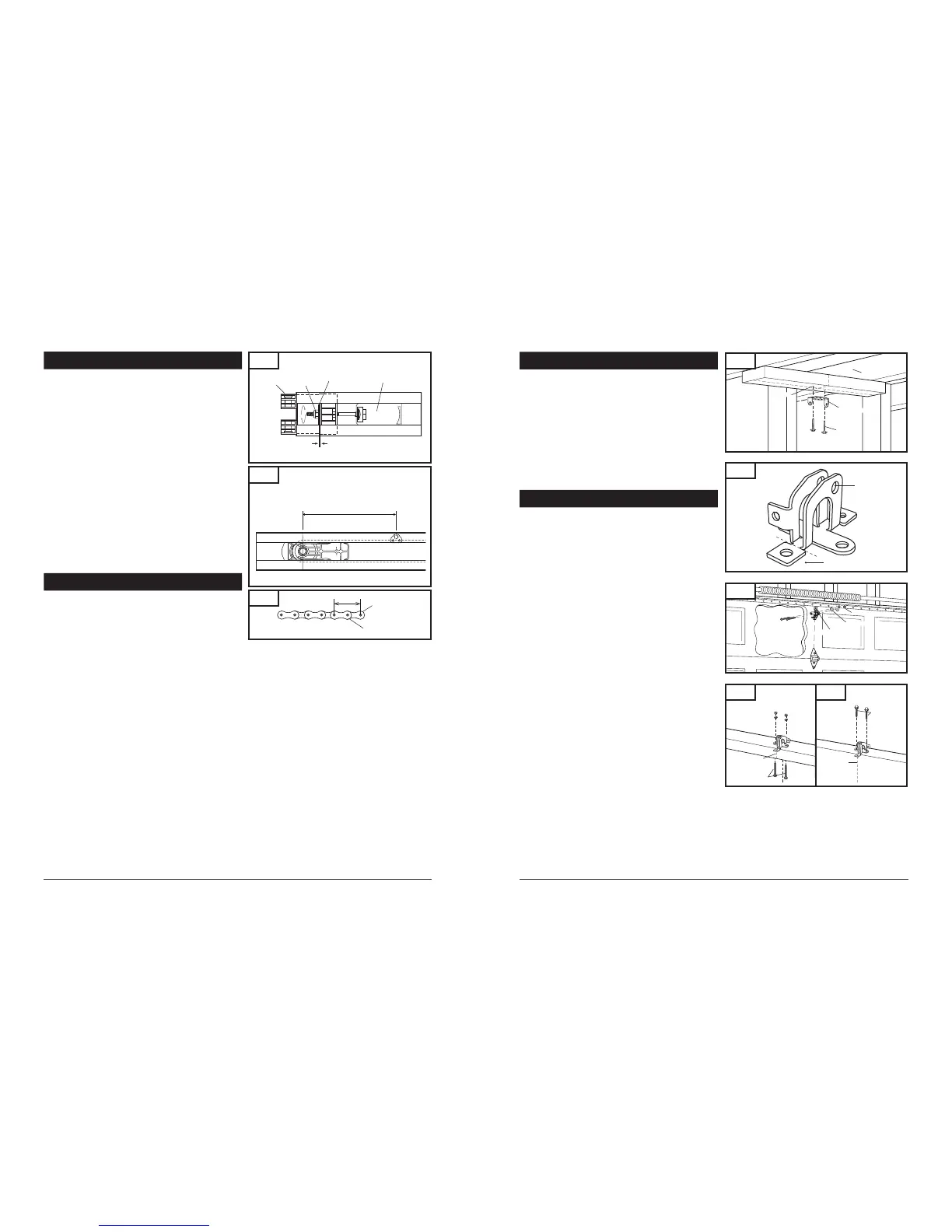

8-3. INSTALL DOOR BRACKET TO DOOR

Fig. 13

Pilot Hole

Ceiling

Header Bracket

Lag Screw

Fig. 12

Cut off for one-piece

door only

Pin Hole

Fig. 14

A. FOR SECTIONAL DOORS:

Wood Sectional Doors (Fig. 14)

Position door bracket (Fig. 13) along vertical center line of

door with pin hole facing top of the door and top edge of

the bracket 4” to 5” below top edge of the door, or roughly

at the same height as top rollers on the door.

Mark locations of securement holes through door bracket.

Drill two 1/4" holes through door for securement of door

bracket.

Insert carriage bolts (1/4” x 2”) from the outside through

door and bracket, then secure with lock washers and nuts

from the inside.

Tighten nuts firmly.

Metal Sectional Doors

Attach door bracket with two teck screws (provided) per Door

manufacturer recommendations.

B. FOR ONE-PIECE DOORS:

Before starting the installation of the door bracket, cut off

mounting leg from opposite side of pin hole.

One-Piece Doors with Exposed Frames (Fig. 15)

Position center of door bracket on the center line on the top

edge of door.

Mark the position where carriage bolts will go through

bracket, and drill two 1/4" holes through top frame of door.

Install carriage bolts from the bottom, through door frame

and bracket, and secure with lock washer and nut from top.

Tighten nuts firmly.

One-Piece Doors without Exposed Frames (Fig. 16)

For doors without exposed frames, use alternate method of

mounting door bracket.

Mark and drill two 3/16" pilot holes into top of frame, then

secure bracket with 5/16" x 1-5/8" lag screws (not provided).

8-2. INSTALL HEADER BRACKET (cont’d)

Insert 1/4-20 x 2”

Carriage Bolts

from outside of door

Lock Washer

1/4-20 Nut

Wood Sectional

Doors

Mark pilot holes location on header through header bracket

holes where lag screws will be inserted.

IMPORTANT: See Fig. 11 for which header bracket holes to

use.

Drill 3/16" pilot holes into header, and install bracket with lag

screws (5/16 x 1-3/4”) provided.

Tighten lag screws firmly.

NOTE: Follow the same procedure if header (shown in Fig.

11) runs vertically instead of horizontally and is the only

option for mounting header bracket to header wall. In case

of minimal clearance above the garage door, the header

bracket may be mounted to the ceiling. Follow the same

steps above to ensure a sound surface for mounting.

Loading...

Loading...