INDUSTRIAL PRINTER QUICK START GUIDE

8

Always follow proper procedures when storing plastic materials. Nylon or Onyx that has absorbed

too much moisture from the air will often cause underextrusion, which can in turn cause print failures.

Please take special care to never leave plastic materials exposed to ambient air, and always keep plastic

materials in the provided drybox.

Note: The term “feed tube” is used in some documentation, and is synonymous with “load tube,”

here.

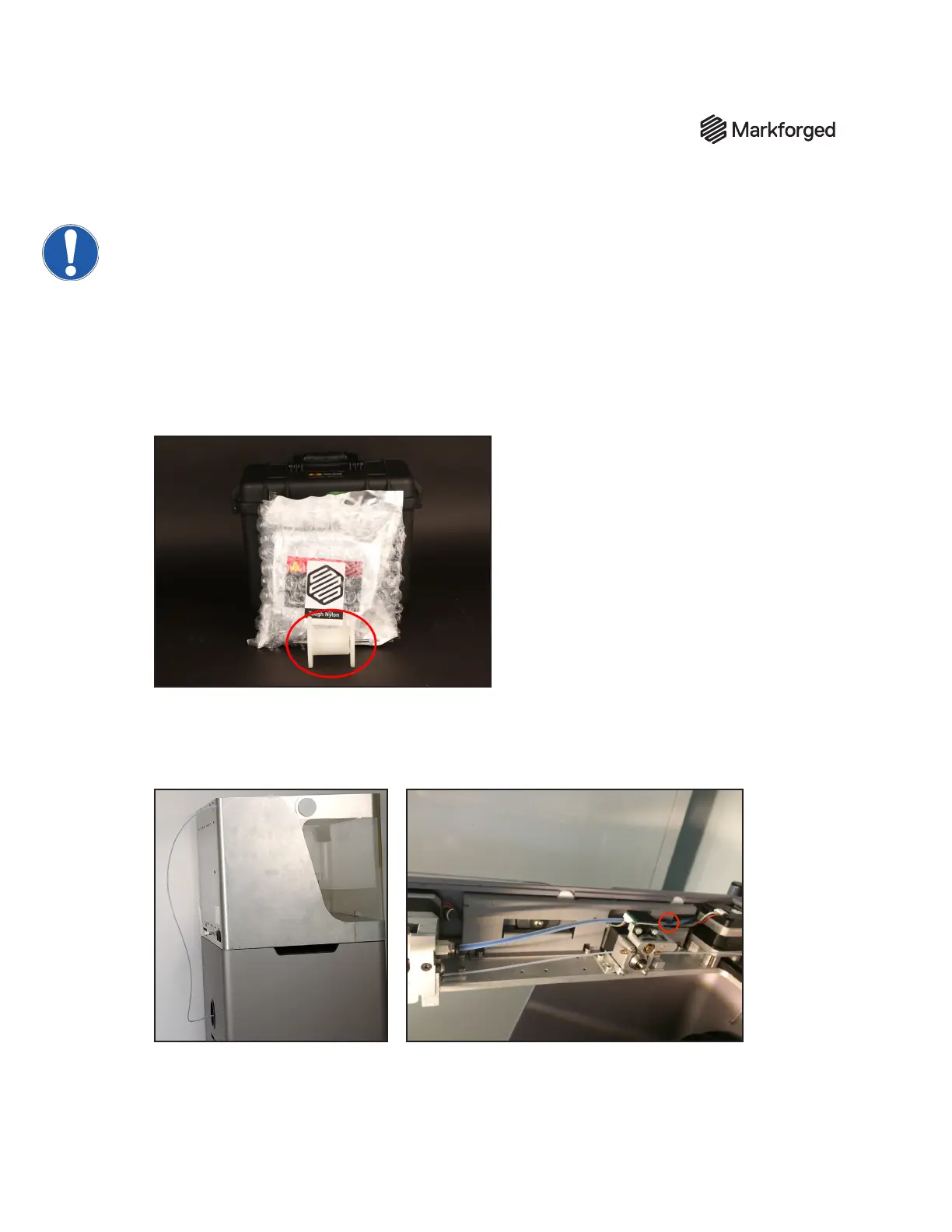

1. Open the drybox inside your printer’s cabinet and remove the spindle from the inside. Discard the

tape and foam wrap from the spindle. Pull the magnetic spindle cap and spindle body apart. (Below:

interior of drybox including wrapped spindle.)

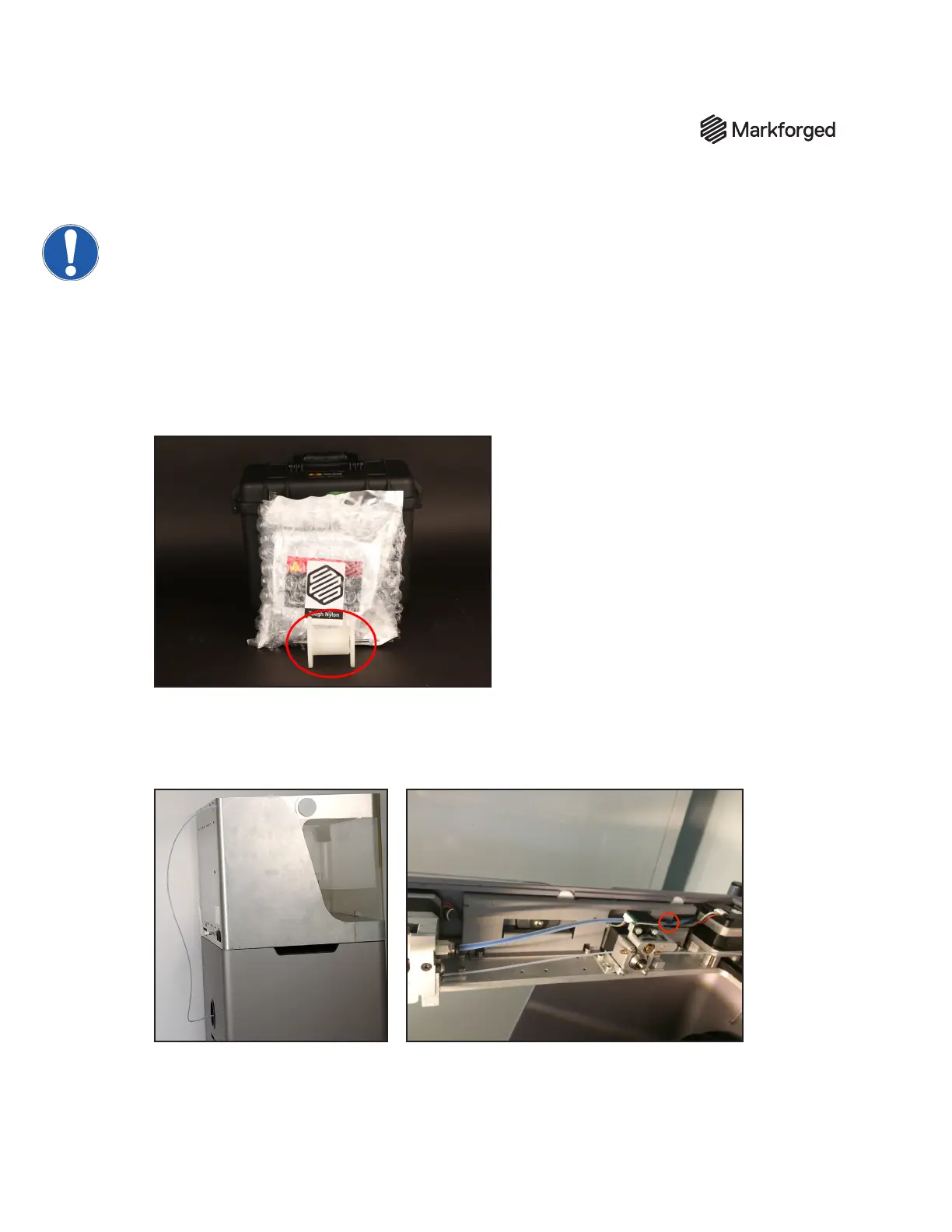

2. Remove the plastic load tube from the accessory kit. Insert one end of the tube through the

opening in the back of the cabinet and into the adapter in the back of the drybox. Feed the other

end of the tube through the opening in the back of your printer, between the stepper motor and

printer casing, and through the clip attached to the printer casing (indicated below).

3. After verifying that the plastic lament material bag has no holes, remove the spool from its

packaging. Place the provided desiccant packs in the corners of the drybox.

Loading...

Loading...