P-Series User Manual Rev2022 35

Troubleshooting and Service Request

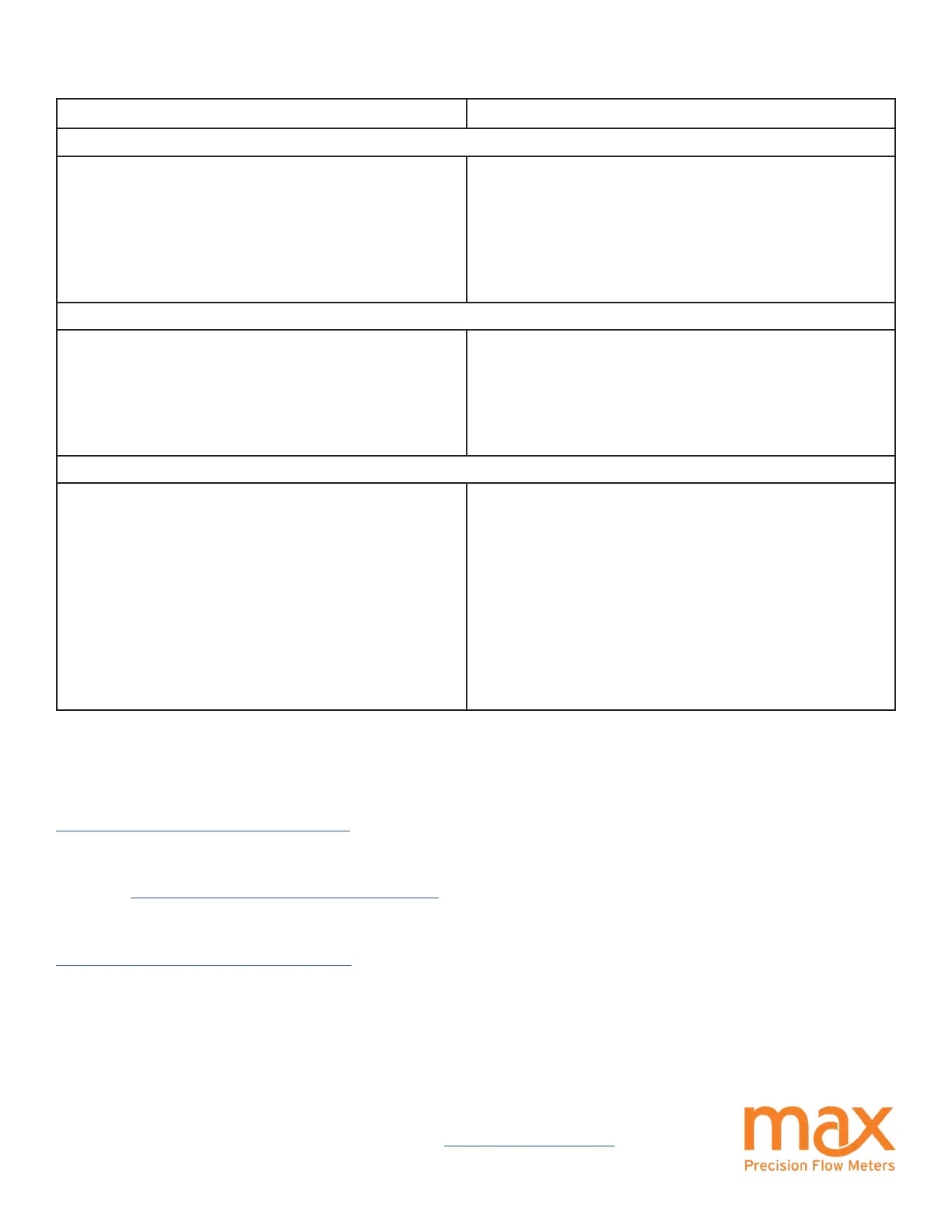

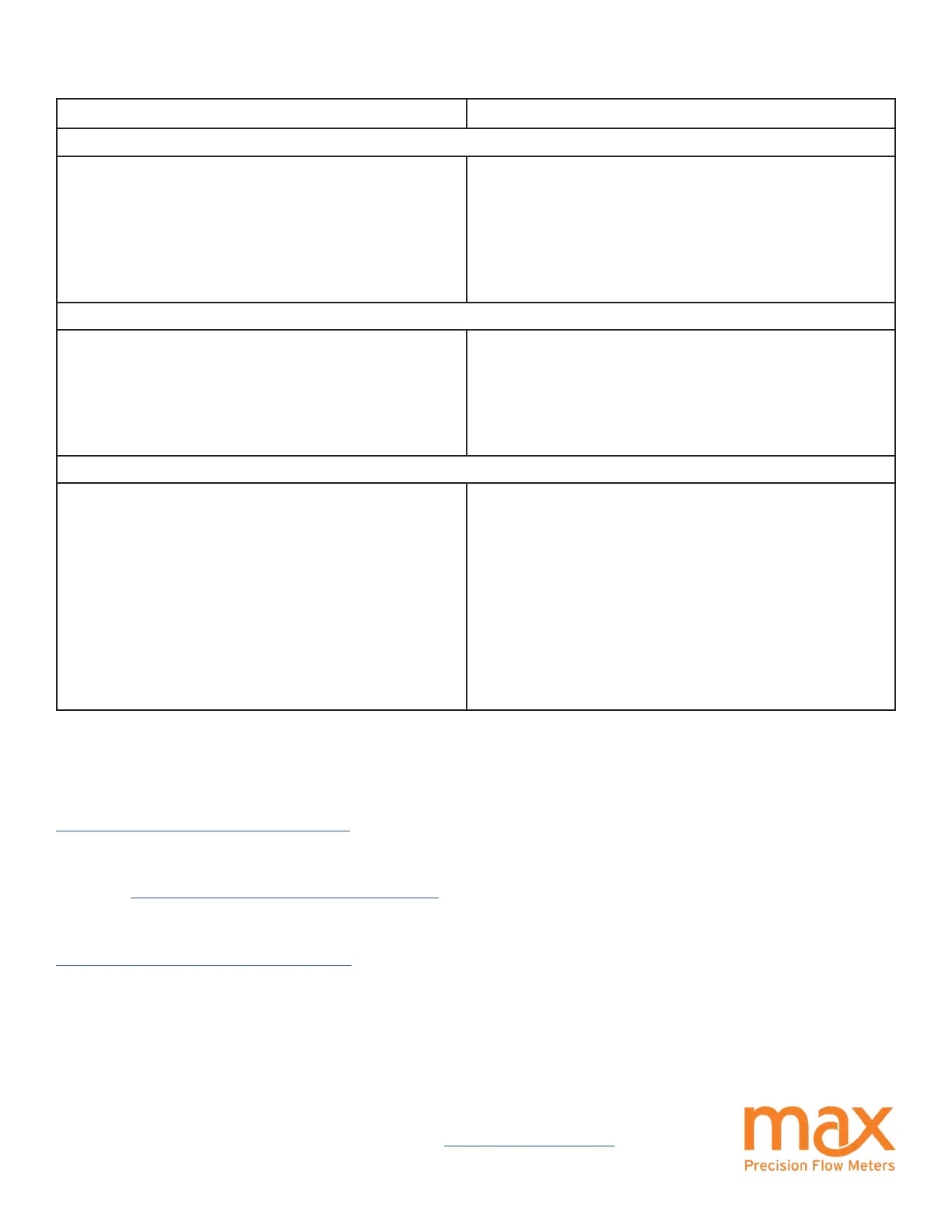

Problem Corrective Action

No Flow through meter or high pressure drop across meter

Solidied material blocking rotation

Debris damage or internally clogged

Meter broken

Heat meter to melt material. Do not exceed maximum

meter operating temperature.

Refurbish meter.

Refurbish meter.

Fluid passes through meter, but no ow is indicated

Transmitter cable or conduit cable incorrectly wired

Meter not turning

Verify DC power is present at the PCA. Use a multi-meter to

measure the transmitter output independent of the display

or PLC.

Refurbish meter.

Indicated ow does not agree with expected readings

Air in the line

Indicator not calibrated properly

Excessive reverse ow in system

Air bubbles displace the meter just like a liquid. If

you see over-reporting, purge all air from lines.

Verify K-Factor for the meter in use and compare

this value to the setting used in the display.

Max transmitters’ anti-dither function buffers up to 1

revolution of reverse ow. An incorrect ow total can be

reported if the system reverse ow is greater than 1 meter

revolution.

Additional Information Available

MMI products are covered under our standard manufacturer’s warranty. Details may be found at

https://www.maxmachinery.com/warranty/.

MMI provides refurbishment and calibration services. For more details or to submit your Service Request, go to

https://www.maxmachinery.com/services/.

Max Machinery, Inc., 33A Healdsburg Avenue, Healdsburg, CA 95448 USA

707.433.2662 | www.maxmachinery.com

Additional information about our products, including STEP les and Sample Calibration sheets, may be found on our

website at https://www.maxmachinery.com/downloads/.

Loading...

Loading...