DONOTOPERATETHET00LNEARAFLAM‐

MABLESUBSTANCE

Neveroperatethetoolnearaflammablesub―

stance(e.9.,thlnner,gaso‖

ne,etc.).VOlatile

fumesfromthesesubstancescouldbedrawn

intothecompressorandcompressedtogether

withtheairandthiscouldresultinanexplosion.

DONOTUSEAWRONGFITTINGS

Theconnectoronthetoolrnustnotholdpressure

whenairsupplyisdisconnected.lfawrongfltting

isused,thetoolcanremainchargedwithairafter

disconnectingandthusvvi‖ beabletodriveafas―

tenerevenaftertheairlineisdisconnected,pos―

siblycausinginiury.

D:SCONNECTTHEAIRSUPPLYANDEMPTY

THEMAGAZINEWHENTHET00LISNOTIN

USE

Alwaysdisconnectthealrsupplyfromthetool

andemptythemagazinewhenoperationhas

beencompletedorsuspended,whenunattend‐

ed,movingtoadifferentworkarea,adiusting,

disassembllng,orrepairingthetool,andwhen

cleanngalammedfastener

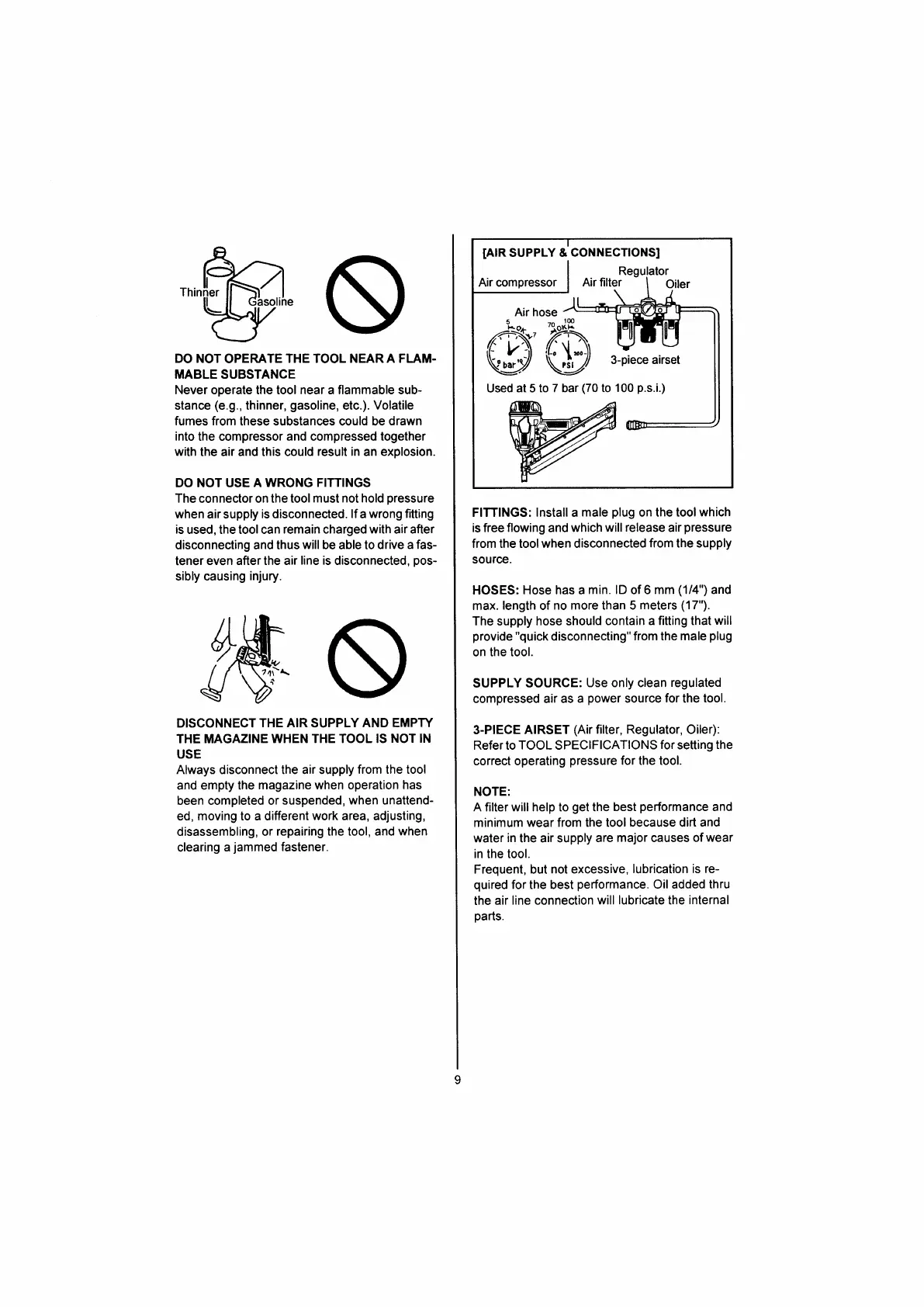

IA:RSUPPLY&CONNECT10NS]

□ 53‑口

eceaISet

Usedat5to7bar(70to100p.s.i.)

FITTINGS:

Installa male

plug

on the toolwhich

is free

flowing

and

which will

release

air

pressure

from the toolwhen disconnected

from the supply

source.

HOSES:

Hose has a

min. lD

of 6

mm

(1/4")

and

max.

length

of

no more than 5

meters

(17").

The

supply

hose should contain

a fitting that

will

provide "quick

disconnecting"

from the male

plug

on the tool.

SUPPLY

SOURCE:

Use only clean

regulated

compressed air as

a

power

source

for

the

tool.

3-PIECE

AIRSET

(Air

filter, Regulator,

Oiler):

Refer to

TOOL

SPECIFICATIONS

for

setting

the

correct operating

pressure

for

the tool.

NOTE:

A filter will help to

get

the

best

performance

and

minimum

wear from the tool because dirt

and

water

in

the air supply

are

major

causes

of wear

in the tool.

Frequent, but

not excessive,

lubrication is

re-

quired

for the best

performance.

Oil added

thru

the air

line connection

will lubricate the

internal

parts.

Loading...

Loading...