11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

33

PLATFORM RAISES BUT LEAKS DOWN

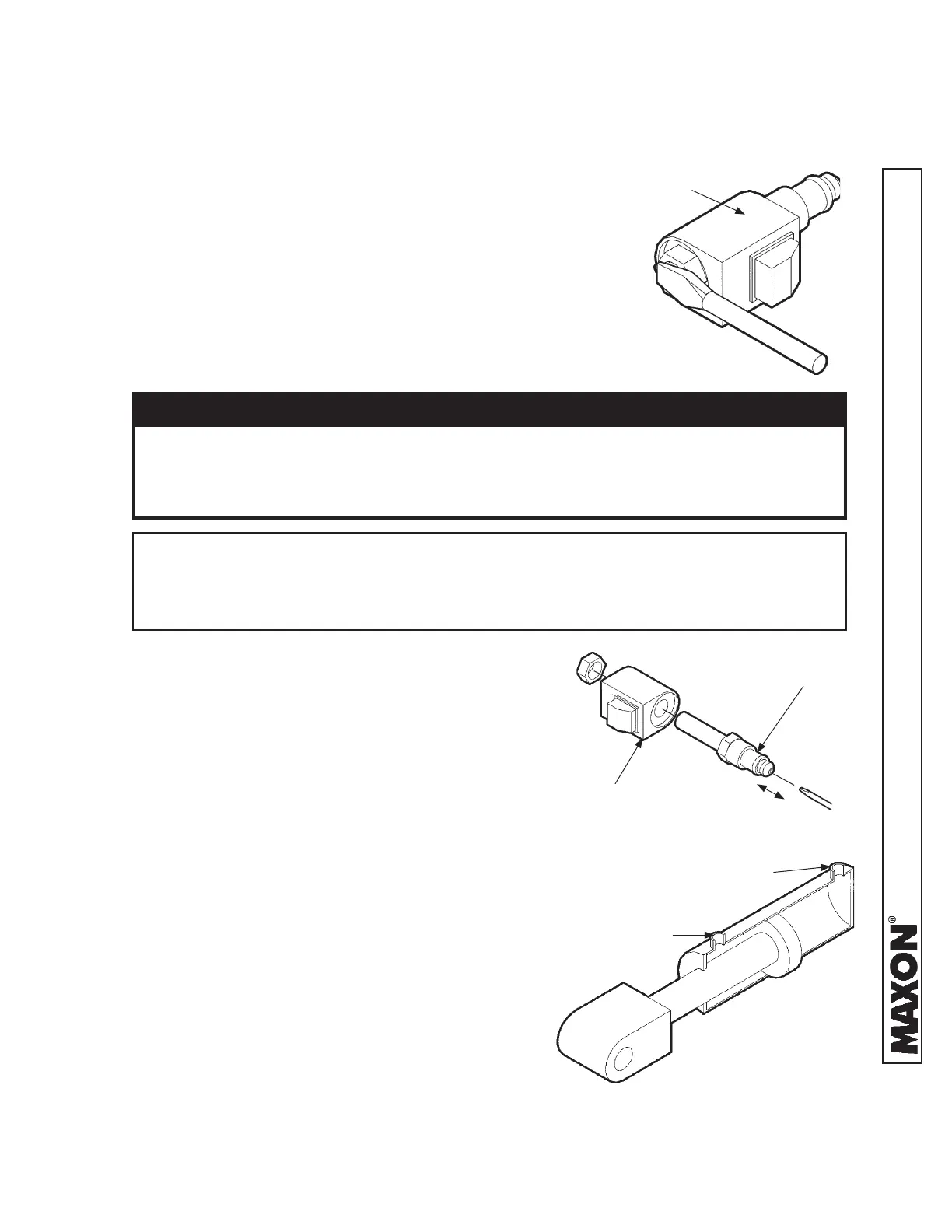

1. Check if solenoid valves are constantly energized by

touching a screwdriver to the top nut of the solenoid

(FIG. 33-1). Try pulling the screwdriver away from the

solenoid. If the solenoid nut attracts the screwdriver

(magnetically) without pushing the toggle switch, the con-

trol circuit is operating incorrectly. Check if toggle switch,

wiring or coil are faulty.

COIL

FIG. 33-1

Keep dirt, water and other contaminants from entering the hydraulic system. Before

opening the hydraulic fl uid reservoir fi ller cap, drain plug and hydraulic lines, clean

up contaminants that can get in the openings. Also, protect the openings from

accidental contamination during maintenance.

CAUTION

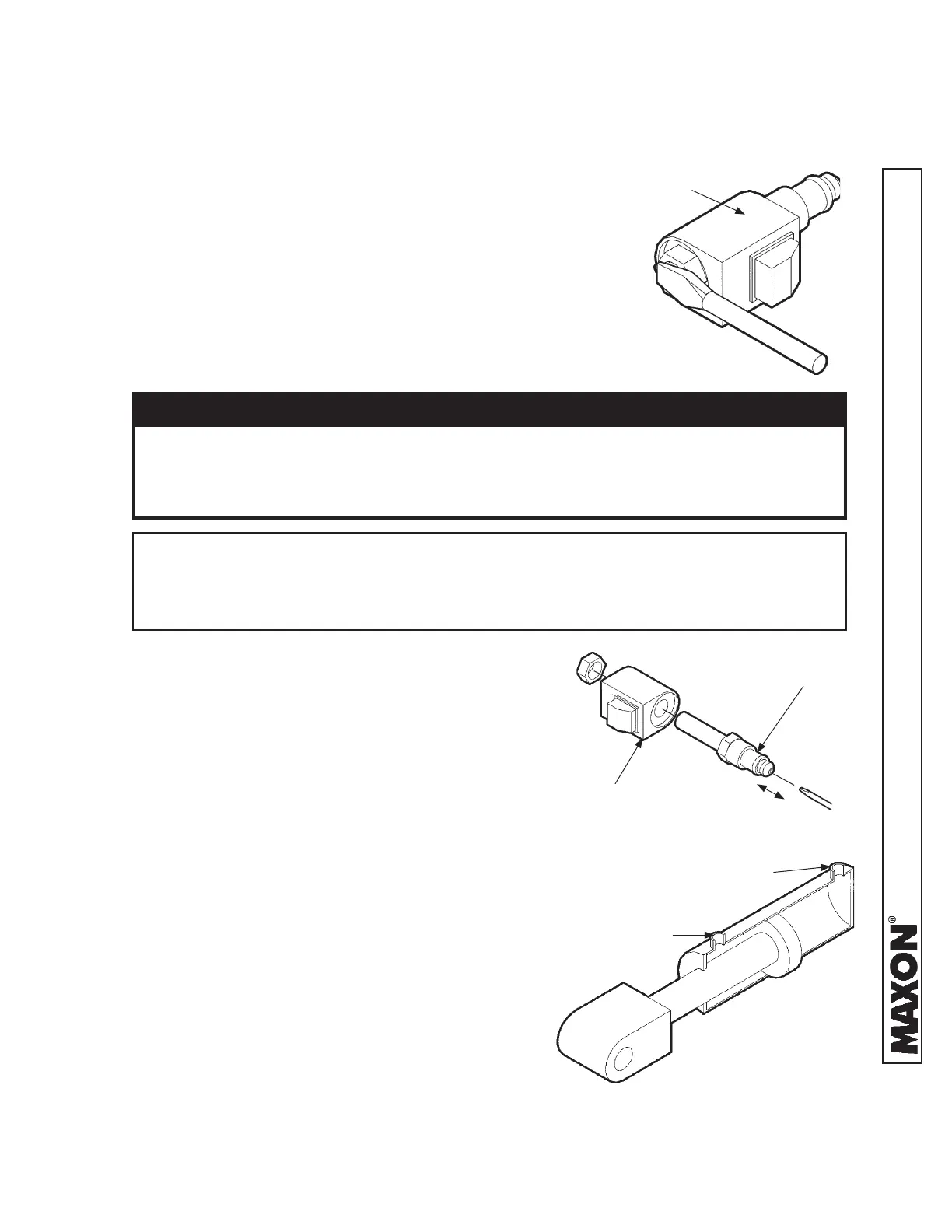

2. Check the valve stem by removing the coil

assembly (Item 1, FIG. 33-2). With platform

on ground, unscrew the valve stem (Item 2,

FIG. 33-2) from the pump. Push on the plunger

that is located inside the valve stem by insert-

ing a small screwdriver blade in the end. If the

plunger does not move freely, (approximately

1/8”) replace the valve stem. When reinstall-

ing valve stem, torque hex nut to 30 in-lbs.

3. Check the hydraulic cylinder. With the platform

on the ground, remove the hydraulic line from

the vent/down port of the cylinder (FIG. 33-

3). Raise the platform even with the bed. Allow

pump motor to run two seconds more while

you watch for hydraulic fl uid at the vent/down

port. A few drops of hydraulic fl uid escaping

the vent/down port is normal; however, if it

streams from the vent/down port, piston seals

are worn. Replace seals.

RAISE PORT

VENT/DOWN PORT

FIG. 33-3

FIG. 33-2

2

1/8”

1

NOTE: In most cases, you can avoid having to manually bleed hydraulic system by

correctly positioning Liftgate platform before disconnecting any lifting cyl-

inder high pressure hydraulic lines. The following procedure can save time

and prevent accidental fl uid spills and hazards.

Loading...

Loading...