RC12 Windlass

Installation procedure

1. Use the Deck Cutout Details drawing as a guide for marking and cutting the holes.

Tip: On GRP boats, running the drill in reverse first will reduce chipping of the gel coat.

Using hole saws, cut the holes for the spacer tube and rope/chain pipe.

2. On GRP or wooden decks, seal the edges of the holes with epoxy to avoid ingress of

moisture.

3. Use of silicon sealant, to seal the windlass to the deck, is highly recommended. For

aluminium boats fit a non-conductive gasket to insulate the deckplate from the deck to

prevent electrolysis.

4. Bolt the deckplate to the deck using mounting studs , washers and nuts. Tighten the nuts

progressively and evenly. Do NOT use power tools. Make sure the installation is firm, but do

not over tighten the nuts.

5. Offer up, from below deck, the drive assembly sliding the mainshaft through the deckplate,

taking care not to damage the deck bearing.

6. After aligning them correctly, bolt the deckplate and spacer tube together, from above deck,

using the M10 hex head screws and spring washers. Tighten them evenly to 35-40 Nm (25-

30 ft lb).

7. Re-check that the position of the drive assembly is satisfactory and convenient for

connecting power supply lines to the motor. Also, make sure that the drive is not in the way

of rope/chain coming into the locker.

8. If a chain counter is used, its sensor should be fitted into the Ø15mm hole in the deckplate,

currently covered with a plastic plug. Make sure the deck is drilled below for the sensor

cable. See brochure supplied with chain counter for detailed assembly instructions.

9. Insert the two retaining clips into the upper groove in the mainshaft; apply some grease to

help keep them in position.

10. Apply anti-seize compound generously over the mainshaft and keyway. Insert key into the

keyway on the mainshaft.

11. Assemble the lower clutch cone making sure it sits nicely on the retaining clips.Apply lithium

based marine grease generously to the conical surface of the clutch cone, to assist with

free falling the anchor.

12. Put the Bellevile washer on top of the lower clutch cone and install the chainwheel assembly

13. Insert key on mainshaft and install upper clutch cone, after applying marine grease to its

conical surface

14. Insert key on mainshaft, assemble drum and washer (Capstan models only).

15. Assemble clutch nut .

16. Put retaining washer on top of the mainshaft and secure it with the screw .

17. Insert the cap into the clutch nut.

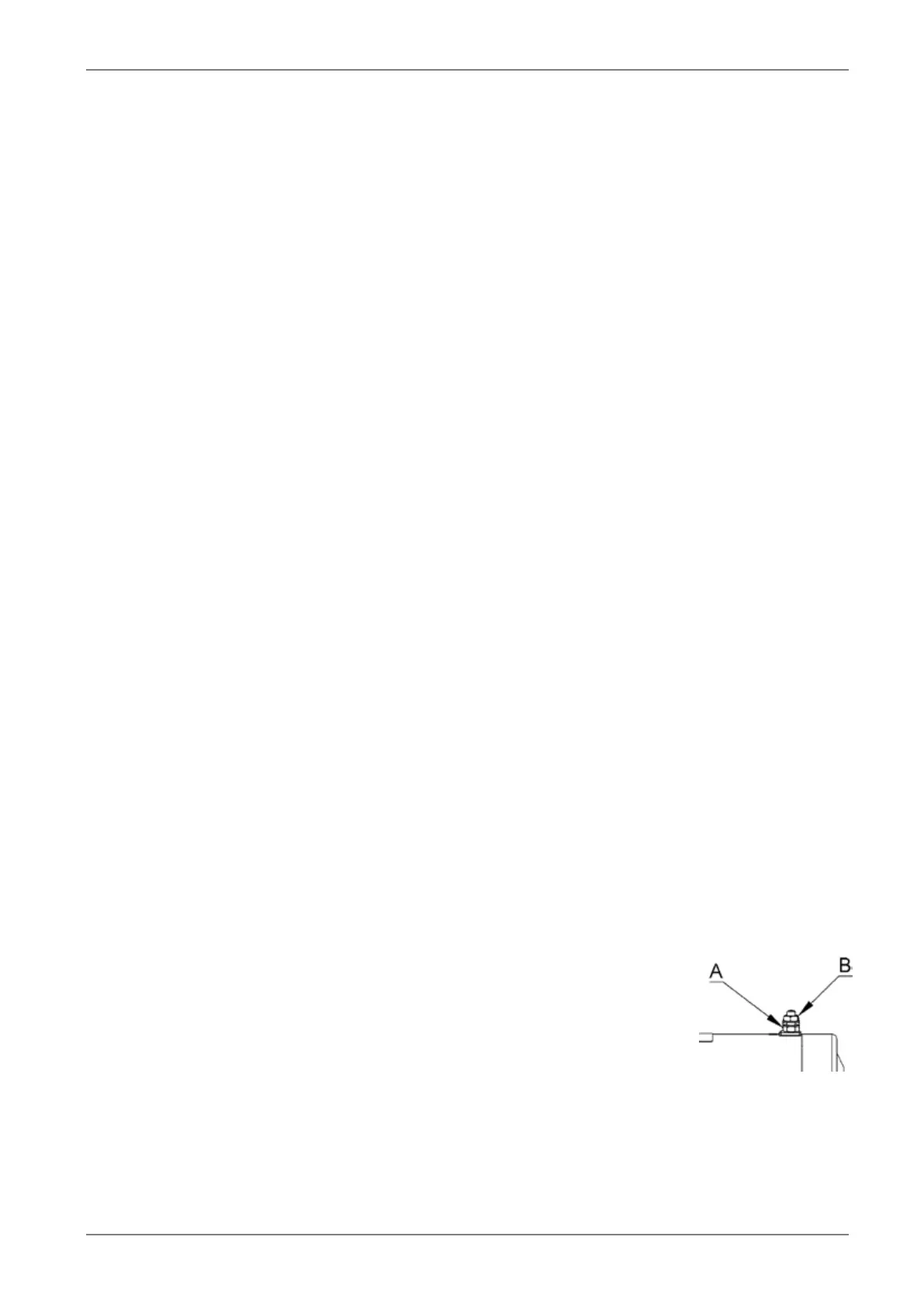

18. When tightening the cables to the motor, ensure the lower nut (A) is

secure against turning when tightening the upper nut (B).

This will prevent damage occurring within the motor.

Complete wiring as per diagram on page18.

Loading...

Loading...