RC12 Windlass

Maintenance

Carrying out the following simple maintenance procedures will provide years of trouble-free

service from the windlass and will ensure that the warranty remains valid.

Recommended lubricants

Gearbox oil

Capacity: 330 ml (10.14 fl oz)

Type: SAE viscosity grade 90-110 (e.g., Shell Omala 320, Castrol

Alpha SP320 or other approved equivalents).

Main shaft, bearing,

and clutch surfaces

Marine grease, Lithium or Lithium complex based

(e.g. Duckhams Keenol or Castrol LMX).

Do not use soap based greases.

Service Intervals

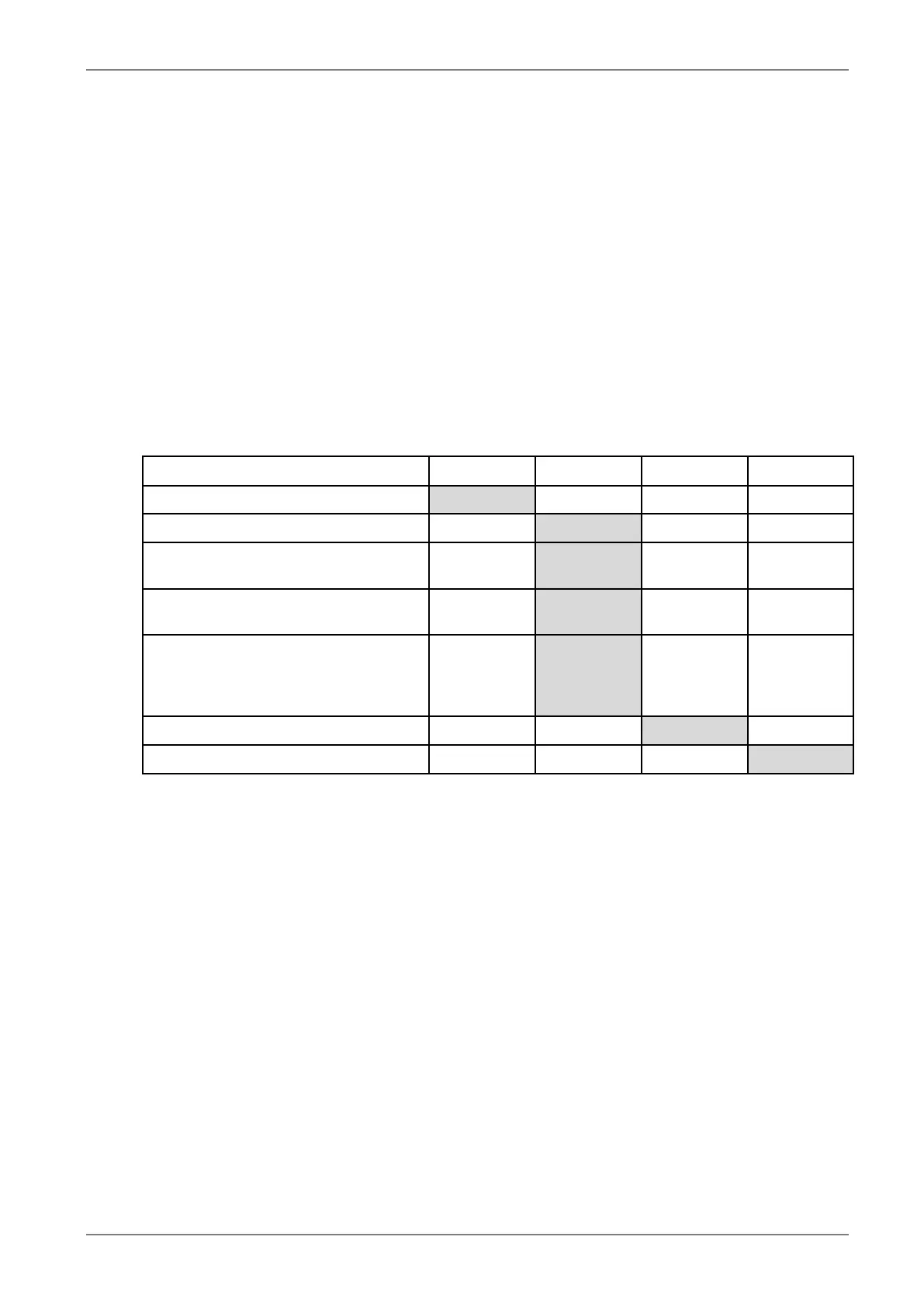

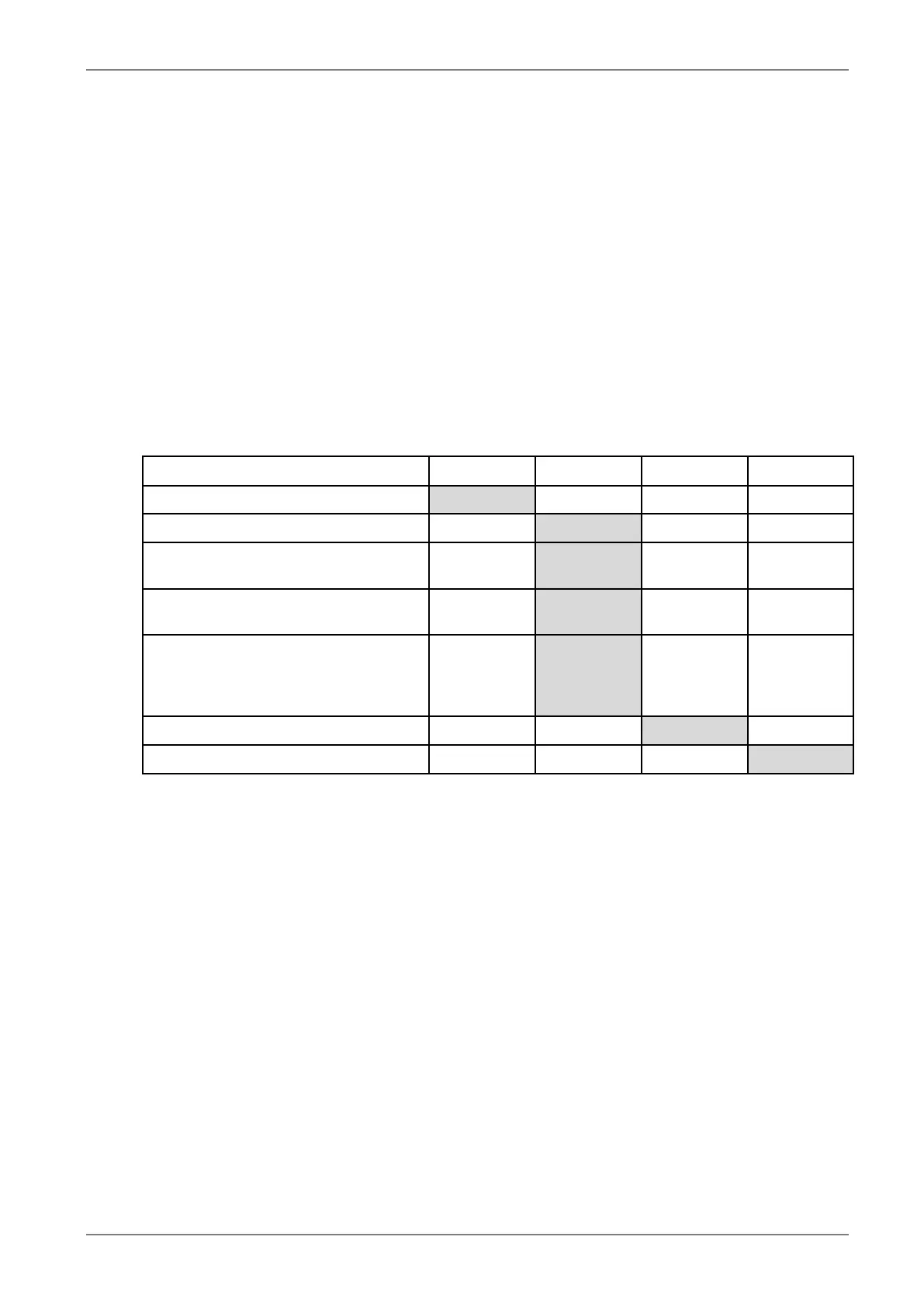

Every trip 3 monthly 12 monthly 3 yearly

Ensure clutches are adjusted correctly

Strip and grease clutches

Remove windlass components, grease

with suitable lubricant

Split gearbox from spacer tube, clean

and re-grease mating faces

Spray fresh water into drainage slot on

gearbox, to breakdown and flush away

any build up of salt/debris, that may

have accumulated

Service motor

Remove gearbox, replace oil and seals

Topworks

The above-deck parts of the windlass should be washed down with fresh water regularly.

Every three months, remove the chainwheel. Refer to exploded diagram, on page 4, for

disassembly.

Use the grease (specified above) and with the aid of a clean brush or non-fluffy rag, lightly grease

the thread on the top end of the shaft and the bores and clutch faces of the parts removed.

Re-assemble in reverse order. IMPORTANT – care must be taken to ensure the key/keys are

properly seated in the shaft.

Clean the Windlass with a cloth damp with Kerosene (paraffin). Spray preferably with CRC3097

“Long Life” or alternatively, CRC6-66 or WD40. Polish off with a clean non-fluffy cloth.

Loading...

Loading...