14

Publication: ZTS-080812

M-B Companies, Inc. 11/15/12

INTRODUCTIONADJUSTMENT AND SERVICE

BRUSH HEIGHT ADJUSTMENT

CAUTION!

If brush height is set too low, the

brush can drive machine rearward

when attachment clutch is engaged.

Engage brush slowly with brush set

at proper height.

For hard surfaces, adjust the caster wheels so that the brush just

touches surface. The brush works best with the brush properly leveled.

To adjust the brush height:

1. With the brush off, move to a dusty, at surface. Leave the

engine running.

2. Start the brush at a slow speed. Run the brush in a stationary

position for 30 seconds.

3. Lift the brush head assembly off the ground and reverse the unit

to move it away from the swept area.

4. Stop engine and allow all moving parts to stop.

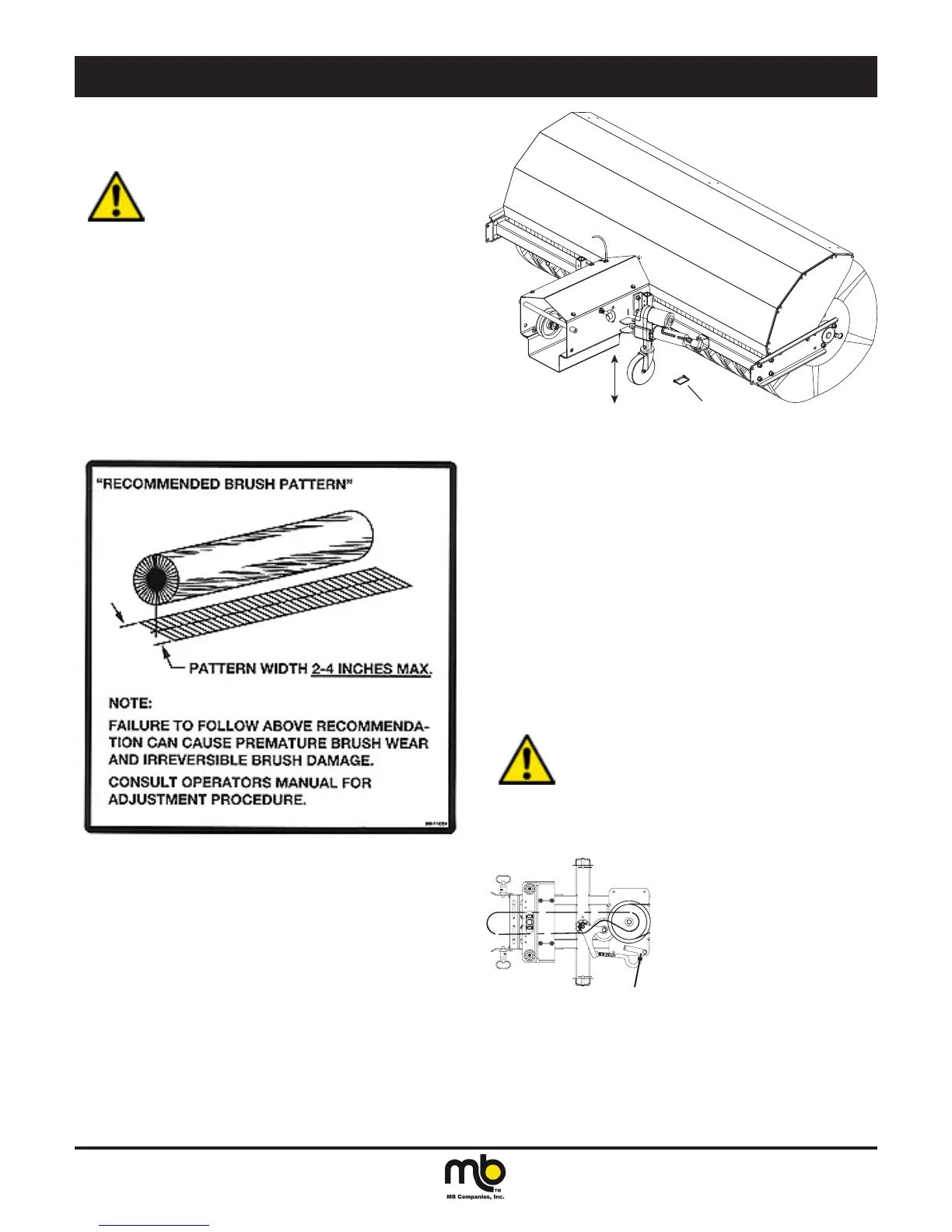

5. Check the width of the swept area. The brush pattern should be

2-3 inches wide, running the length of the brush. (See Figure 14

Brush Sweeping Pattern)

Figure 14 Brush Sweeping Pattern

6. To adjust:

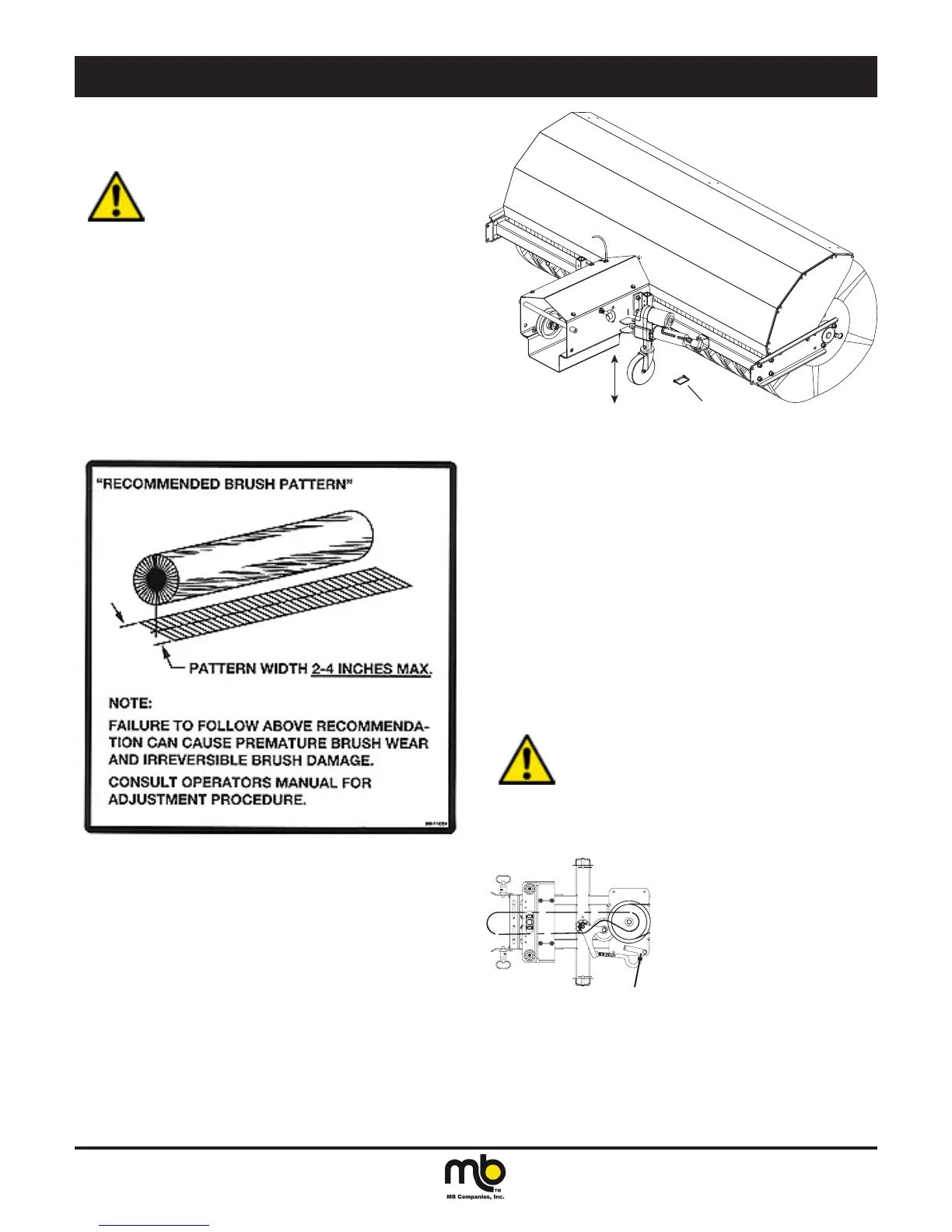

a. Remove the caster wheel lock pin. (See A, Figure 15 Pattern

Adjustment).

b. Raise or lower the caster wheel as needed.

c. Insert the caster wheel lock pin into the hole in the caster

bracket and through the caster tube. Use the attached spring

clip to secure the pin.

NOTE: If using the power broom for turf applications, less ground

contact is required.

A. Caster Wheel Lock Pin

Figure 15 Pattern Adjustment

Adjust for Wear

As the broom core wears the diameter of the broom is smaller. The

brush pattern will become smaller causing the sweeping action to be

ineffective.

To regain the correct brush pattern, the casters are raised up.

BELT REPLACEMENT

The tension on the two belts is maintained by the tension pulleys. Over

time the belts will wear and may pull apart.

Visually inspect the belts for signs of wear. The belts may become

narrow and ride low in the pulleys. Also look for frayed edges and parts

missing.

WARNING!

Do not work on drive belts while

the engine is running. Turn off the

engine and allow parts to cool.

To replace the belts:

1. Lower the attachment to its lowest position.

2. Release the two tension pulleys.

Push in to release.

Figure 16

3. Remove the rear belt to the engine. Refer to the Attachment

Mount Installation manual.

4. Remove the front belt.

5. The front belt is installed rst by placing it over the center pulley.

Loading...

Loading...