16

Publication: ZTS-080812

M-B Companies, Inc. 11/15/12

INTRODUCTIONMAINTENANCE

MAINTENANCE SCHEDULE

Maintenance

Required

Service Interval Notes

Lubricate center

pulley bearings

10 Hours Use 10W Oil and

Automotive Lithium Grease

Lubricate spline shaft

for driveline

Yearly Use Automotive Lithium

Grease

Lubricate lock pin on

manual swing

Yearly Use Automotive Lithium

Grease

Check/Change

engine oil**

Check oil before

each use**

None

Replace spark plug** Yearly** None

Check drive linkage

and belt tension

Before each use None

Lubricate pivot and

friction points

10 Hours Use 10W Oil

** See your engine owner’s manual for engine-related information.

LUBRICATION

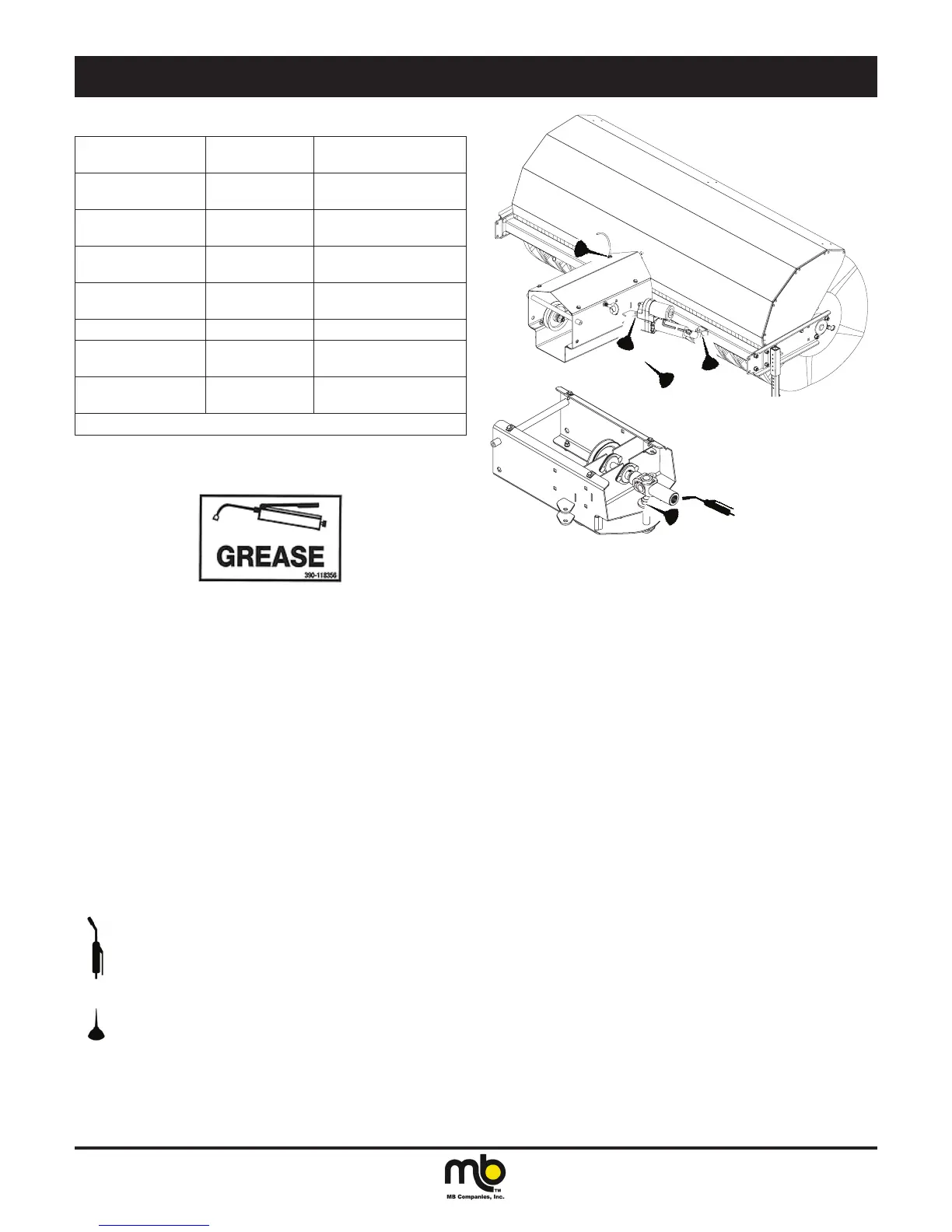

NOTE: Grease points are noted with an applicable decal.

Grease bearings and pivot points per the MAINTENANCE SCHEDULE

using Chevron Ultra Duty II, Grade 2; or equivalent high-temp grease.

IMPORTANT! It is very important that grease ttings on the

broom shaft are lubricated regularly. If broom

rusts to shaft, damage to worm gear may occur

if shear pins do not break.

To prevent wheels rusting to axles, it is also

necessary to remove the wheels and grease

the axles regularly.

1. Apply medium weight (10W) oil to points shown.

2. Remove wheels and grease axles once each year.

3. Grease broom drive universal joint.

NOTE: Access is best gained from underneath machine.

4. Grease broom pivot pin.

Generally, all moving metal parts should be oiled where contact is

made with other parts. Keep oil and grease off belts, pulley grooves,

drive disc, and friction disc.

LUBRICATION NOTES:

Grease locations indicated by grease gun symbol. Use

grease ttings when present. Disassemble parts to apply

grease to moving parts when grease ttings are not

installed.

Oil locations indicated by oil can symbol. Do not allow oil to

drip onto traction drive or friction disc.

Figure 21

Loading...

Loading...