15

Publication: ZTS-080812

M-B Companies, Inc. 11/15/12

INTRODUCTIONADJUSTMENT AND SERVICE

6. Route the belt from the lower center pulley under the tension

pulley.

7. Position the belt under the two front pulleys and up to the broom

drive pulley.

Figure 17

8. When the belt is in position, pull out on the lever to engage the

tensioner.

9. To install the rear V-belt to the engine pulley refer to the

Attachment Mount Installation manual.

SHEAR PIN REPLACEMENT

DANGER! Do not go near the broom when the

engine is running. Do not run the engine

with any cover or guard removed.

Under most circumstances, if the broom strikes an object which could

cause damage to the unit, the shear pin(s) will break. This protects the

gear box and other parts from damage. The shear pins are located on

the broom shaft.

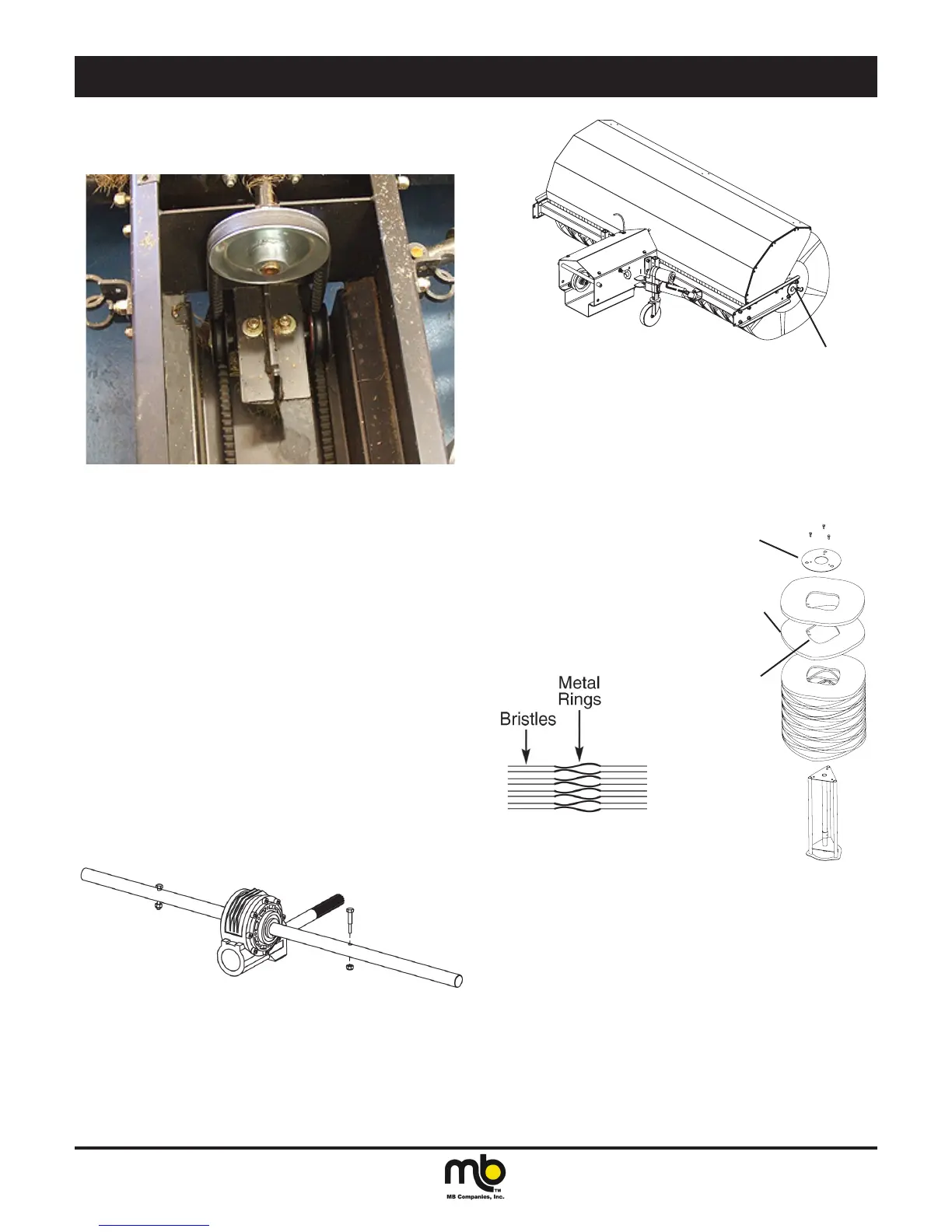

See Figure 18 Shear Pin Replacement.

To replace the shear pins:

1. Tap out the broken pin(s) with a pin punch.

IMPORTANT! Do NOT replace shear pins with anything other

than the correct grade replacement shear pin.

Use of bolts, screws or a harder shear pin will

lead to damaged equipment.

2. Install new shear pin(s) and secure with nut.

Figure 18 Shear Pin Replacement

BRUSH SEGMENT REPLACEMENT

1. Remove bolts from broom bearings at both ends of the support

shaft (Figure 19 Brush Removal).

Attachment Bolts

Figure 19 Brush Removal

2. Loosen bearing setscrews and slide bearings inwards toward

the center of broom.

3. Move power unit backwards away from the brush assembly. The

brush and gearbox will pull free from the drive pulley shaft.

IMPORTANT! Support splined drive shaft to prevent damage.

4. Stand broom assembly on one end. (See Figure 20 Brush

Assembly)

A. End Plate C. Engagement Fingers

B. Brush Segment

Positioned Hill to Hill

Valley to Valley

A

B

C

Figure 20 Brush Assembly

5. Remove the three bolts from the end plate (See A, Figure 20

Brush Assembly).

6. Remove used broom segments.

7. Install new broom segments. Position the segment cores to

provide hill to hill valley to valley contact.

NOTE: Align segment engagement ngers (C, Figure 20 Brush

Assembly) on alternating support shafts. This will evenly

spread rotating force through the drive system.

8. Reinstall broom assembly.

IMPORTANT! Fully tighten the bearing setscrews before

operating the power broom.

Loading...

Loading...