3.

Before making or checking carburetor adjustments, in-

stall

the bar and chain and be

sure

that the chain is

being lubricated properly. A properly lubricated chain

will throw a fine spray of oil off the nose of the bar when

the chain is moving at operating

speeds.

4.

Before checking carburetor

adjustments,

be

sure

that the

air

filter is

clean

and

securely

in place on the air box.

5.

All engines lose power as altitude

increases.

This

is due

to the "thin" air

(less

oxygen in the atmosphere at

higher

altitudes).

The rate of power

loss

is approximately

3%

per 1,000 feet (300 meters) of elevation. Therefore,

an

engine will develop only 85% of its sea level power at

an

altutude of 5,000 feet (1,500

meters),

and only 70%

at

10,000 feet (3,000

meters).

Other factors,

such

as

temperature and humidity, will affect power

output

also.

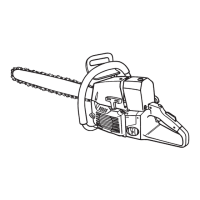

Adjustment

Procedures

NOTE:

The PM 650 has a built-in, automatic high speed

governor.

This

governor is pre-set at the factory to provide the

best

engine RPM for power and overall engine performance,

including best fuel economy. The governor

also

prevents the

engine

from running at

excessive

RPM's

which can

cause

severe

engine damage. Tampering with the governor is

considered

abuse

and will void the

warranty.®

1.

Gently

turn

the LOW

SPEED

and

HIGH

SPEED

MIXTURE

NEEDLES

in

(clockwise)

until

they

seat,

then

turn

both

needles

out (counterclockwise) one

full

turn.

2.

Adjust the

IDLE

SPEED

SCREW

until

the

throttle

plate is

just

slightly open.

3.

Start the engine and let it warm up thoroughly at low

speed.

CAUTION:

When making carburetor adjustments or

testing the unit for

full

throttle

operation, never run the

engine

at

full

throttle

without

a cutting load for more than

a

few moments.

Excessive

full

throttle

operation while

not cutting can

cause

serious engine damage.

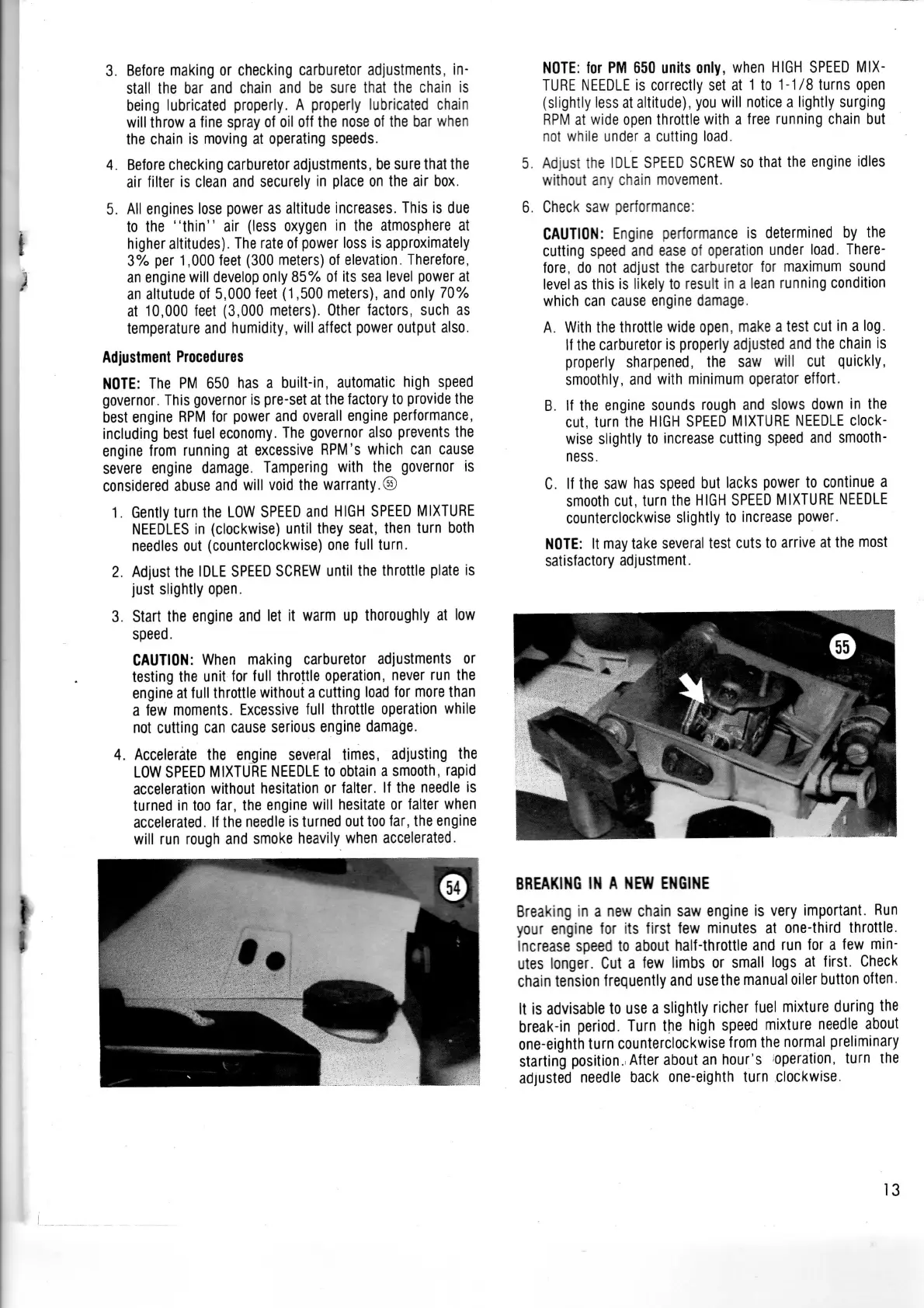

4.

Accelerate the engine

several

times, adjusting the

LOW

SPEED

MIXTURE

NEEDLE

to obtain a smooth, rapid

acceleration

without

hesitation or falter. If the needle is

turned in too far, the engine will hesitate or falter when

accelerated.

If the needle is turned out too far, the engine

will run rough and smoke heavily when

accelerated.

NOTE:

for PM 650 units only, when

HIGH

SPEED

MIX-

TURE

NEEDLE

is correctly set at 1 to 1-1/8 turns open

(slightly

less

at altitude), you will notice a

lightly

surging

RPM

at wide open

throttle

with a free running chain but

not while under a cutting load.

5.

Adjust the

IDLE

SPEED

SCREW

so that the engine idles

without

any chain movement.

6.

Check

saw performance:

CAUTION:

Engine

performance is determined by the

cutting speed and

ease

of operation under load.

There-

fore,

do not adjust the carburetor for maximum sound

level

as this is likely to result in a lean running condition

which

can

cause

engine damage.

A.

With the

throttle

wide open, make a test cut in a log.

If

the carburetor is properly adjusted and the chain is

properly sharpened, the saw will cut quickly,

smoothly, and with minimum operator effort.

B.

If the engine sounds rough and

slows

down in the

cut,

turn

the

HIGH

SPEED

MIXTURE

NEEDLE

clock-

wise

slightly to

increase

cutting speed and smooth-

ness.

C.

If the saw has speed but

lacks

power to continue a

smooth cut,

turn

the

HIGH

SPEED

MIXTURE

NEEDLE

counterclockwise

slightly to

increase

power.

NOTE:

It may take

several

test cuts to arrive at the most

satisfactory

adjustment.

BREAKING

IN A NEW

ENGINE

Breaking

in a new chain saw engine is very important. Run

your engine for its first few minutes at one-third

throttle.

Increase

speed to about half-throttle and run for a few min-

utes

longer. Cut a few limbs or small logs at first.

Check

chain

tension frequently and

use

the manual oiler

button

often.

It is advisable to use a slightly richer fuel mixture during the

break-in

period. Turn the high speed mixture needle about

one-eighth

turn

counterclockwise from the normal preliminary

starting position. After about an hour's operation,

turn

the

adjusted

needle back one-eighth

turn

clockwise.

13

Loading...

Loading...