FUEL

TANK

FILTER

SPROCKET,

CLUTCH

AND

CLUTCH

DRUM

The

fuel tank

filter

prevents

dirt

from

entering the fuel line to

the carburetor. After

a

while,

dirt

will

build

up on the

filter

and

will

cut

down

the

flow

of fuel. Or, if water is

permitted

to enter

the fuel tank, the water

will

get

into

the

filter

and prevent the

flow

of fuel to the carburetor. If any

condition

affects the

filter,

install a new

filter.

However, if a new

filter

is not available the

filter

can be cleaned for temporary use.

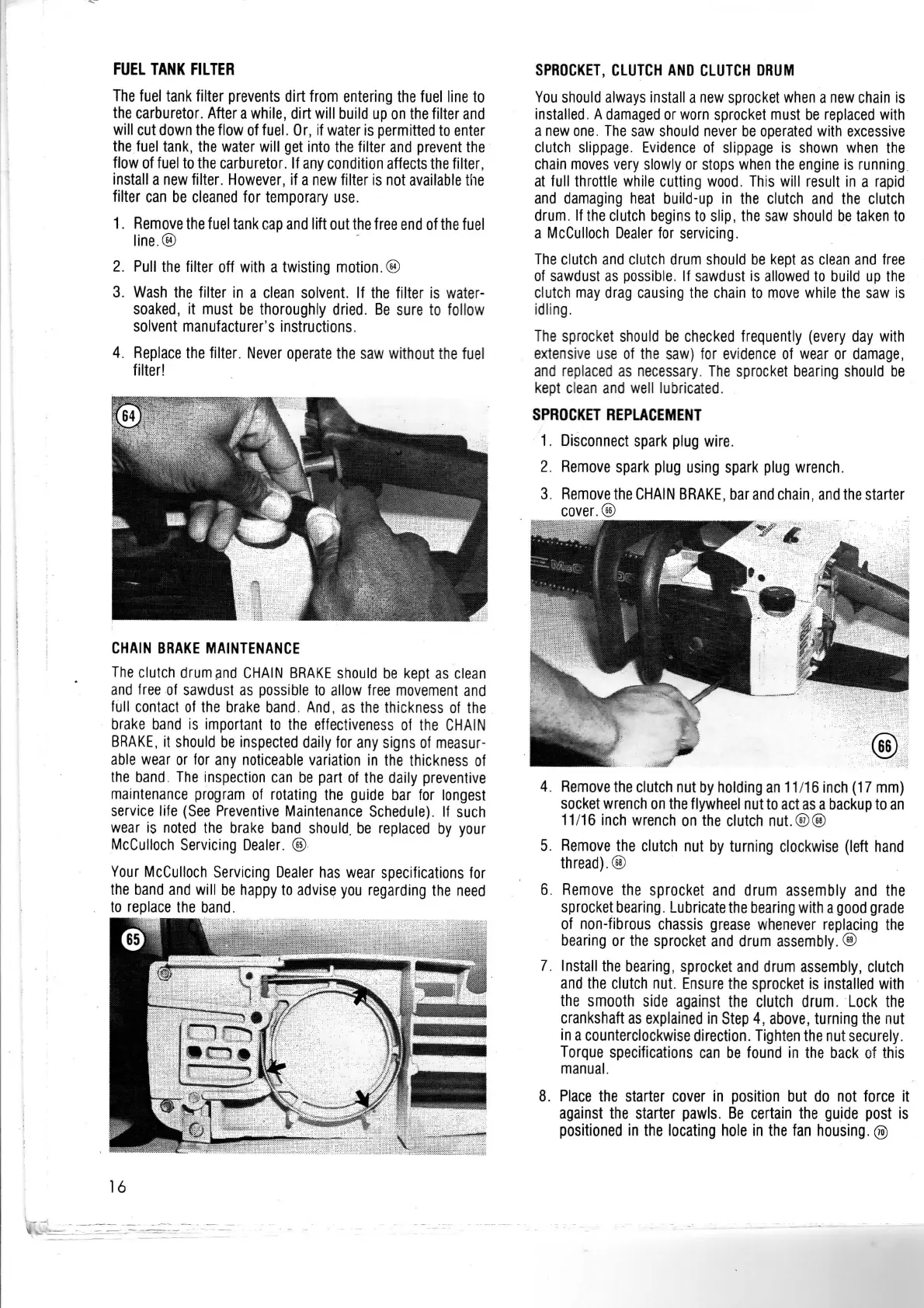

1.

Remove

the fuel tank cap and

lift

out the free end of the fuel

line.®

2.

Pull the

filter

off

with

a

twisting

motion.®

3.

Wash the

filter

in a clean solvent. If the

filter

is water-

soaked,

it must be

thoroughly

dried. Be sure to

follow

solvent manufacturer's instructions.

4.

Replace the

filter.

Never operate the saw

without

the fuel

filter!

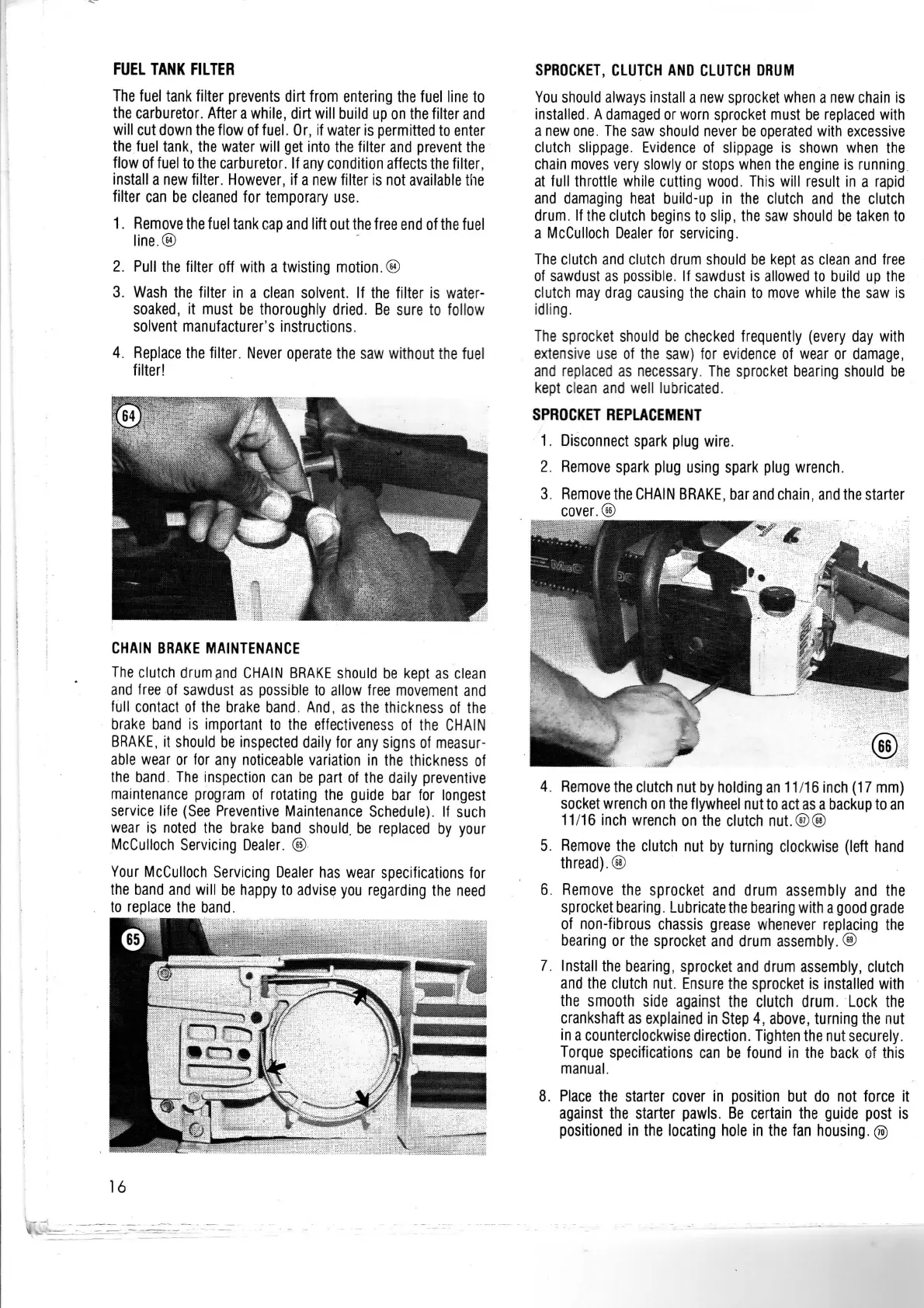

CHAIN

BRAKE

MAINTENANCE

The

clutch

drum

and CHAIN

BRAKE

should be kept as clean

and free of sawdust as possible to allow free movement and

full

contact of the brake band. And, as the thickness of the

brake band is

important

to the effectiveness of the CHAIN

BRAKE,

it should be inspected daily for any signs of measur-

able wear or for any noticeable variation in the thickness of

the band. The inspection can be part of the daily preventive

maintenance program of

rotating

the guide bar for longest

service

life

(See Preventive Maintenance Schedule). If such

wear

is

noted

the brake band should, be replaced by your

McCulloch Servicing Dealer. ®

Your

McCulloch Servicing Dealer has wear specifications for

the band and

will

be happy to advise you regarding the need

to replace the band.

You

should always install a new sprocket when a new chain is

installed. A damaged or worn sprocket must be replaced

with

a

new one. The saw should never be operated

with

excessive

clutch slippage. Evidence of slippage is shown when the

chain moves very slowly or stops when the engine is running

at

full

throttle

while

cutting

wood.

This

will

result in a rapid

and damaging heat

build-up

in the clutch and the clutch

drum. If the clutch begins to slip, the saw should be taken to

a

McCulloch Dealer for servicing.

The

clutch and clutch

drum

should be kept as clean and free

of sawdust as possible. If sawdust is allowed to

build

up the

clutch may drag causing the chain to move while the saw is

idling.

The

sprocket should be checked frequently (every day

with

extensive

use of the saw) for evidence of wear or damage,

and replaced as

necessary.

The sprocket bearing should be

kept clean and well lubricated.

SPROCKET

REPLACEMENT

1.

Disconnect spark

plug

wire.

2.

Remove spark

plug

using spark

plug

wrench.

3.

Remove

the

CHAIN

BRAKE,

bar and chain, and the starter

cover.®

4.

Remove the clutch nut by

holding

an 11/16 inch (17 mm)

socket

wrench on the flywheel nut to act

as a

backup to an

11/16

inch wrench on the clutch

nut.®®

5.

Remove the clutch nut by

turning

clockwise (left hand

thread).®

6.

Remove the sprocket and

drum

assembly and the

sprocket bearing. Lubricate the bearing

with

a

good

grade

of non-fibrous

chassis

grease whenever replacing the

bearing or the sprocket and

drum

assembly. ®

7.

Install the bearing, sprocket and

drum

assembly, clutch

and the clutch nut.

Ensure

the sprocket is installed

with

the smooth side against the clutch drum. Lock the

crankshaft

as explained in Step 4, above,

turning

the nut

in a counterclockwise direction. Tighten the nut securely.

Torque specifications can be

found

in the back of this

manual.

8.

Place

the starter cover in

position

but do not force it

against

the starter pawls. Be certain the guide post is

positioned in the locating hole in the fan housing. @

16

Loading...

Loading...