CHAIN MAINTENANCE

CHAIN SHARPENING ®

How you care for your chain saw defermines the

kind

of

service

you

will

get

from

it.

The

use of McCulloch Depth Gauge Tools and a McCulloch

File

Guide is recommended.

Chain

should be kept clean and sharp for maximum

cutting

efficiency.

CAUTION:

Always wear protective gloves when handling

chain.

CHAIN TENSION

Check

the chain tension frequently and adjust as

often

as

necessary

to keep chain snug on the bar, but loose enough

to be pulled around the bar by hand.

Over

a

period

of

time

the moving parts of saw chain

become worn which results in what is referred to as "chain

stretch".

When it is no longer possible to

obtain

the correct

chain tension adjustment, a

link

will

have to be removed to

shorten the chain. See your McCulloch Servicing Dealer to

have

this repair performed.

CAUTION:

Never have more than three (3) links removed

from

a

chain.

This

could

cause

damage to the sprocket.

NEW CHAIN BREAK-IN

1.

Run chain at low speed

without

cutting

for 5 minutes.

Push

manual oiler

button

every 10 to 15 seconds to pro-

vide extra oil.

2.

After 5 minutes, shut off engine and recheck and adjust

chain tension.

3.

Keep the chain well lubricated.

4.

Restart and after 10 minutes, shut off engine and check

chain tension. Adjust if

necessary.

Repeat chain tension

check

often

during

the first few hours of cutting.

CHAIN LUBRICATION

Make sure manual and automatic oiler are working. Keep oiler

tank

filled

with

clean McCulloch

Chain,

Bar and Sprocket Oil.

Use

plenty of oil on chain when cutting. Never let chain run

dry on the bar. In abrasive wood, use extra oil.

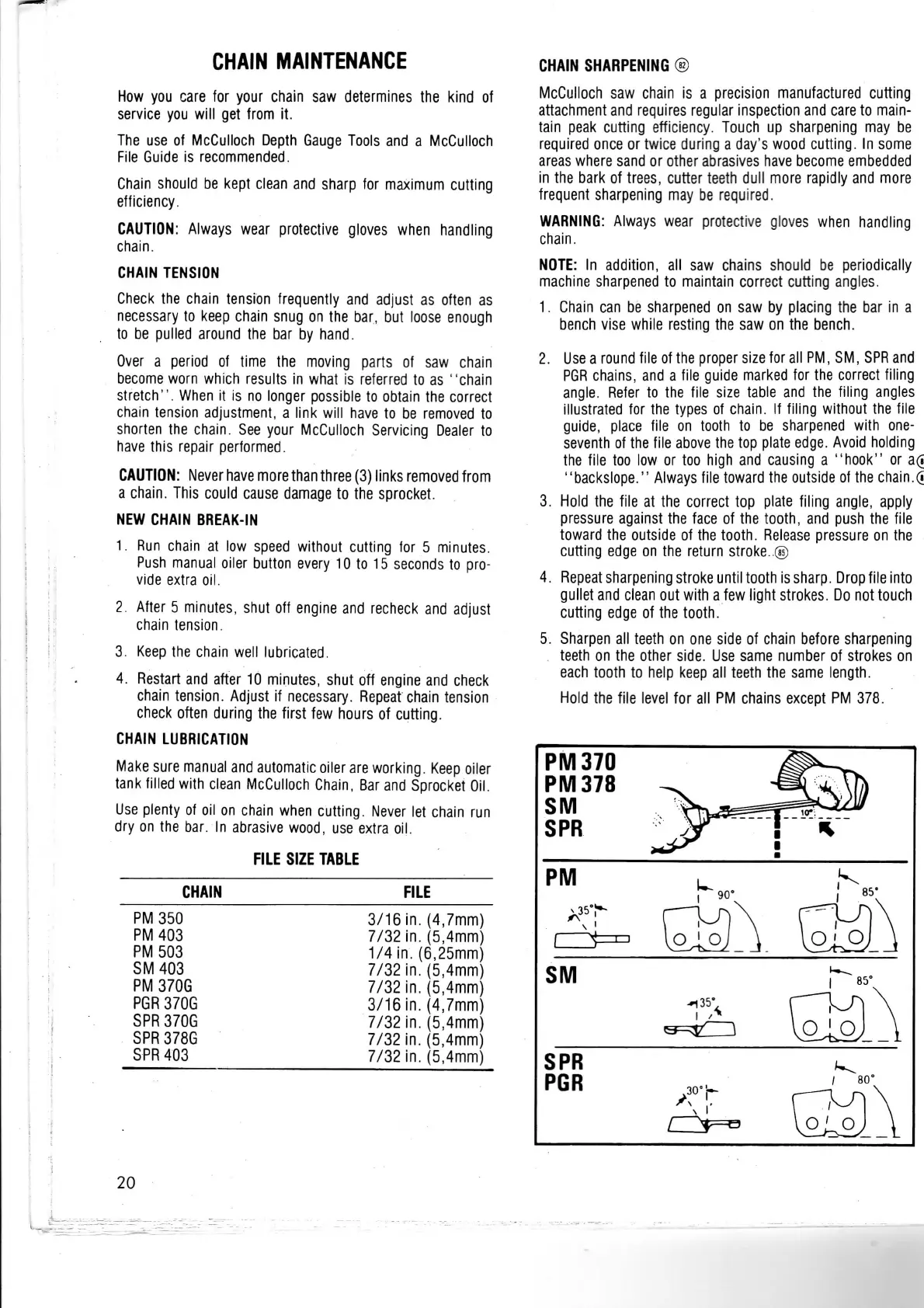

FILE

SIZE

TABLE

CHAIN

FILE

PM

350

PM

403

PM

503

SM

403

PM

370G

PGR

370G

SPR

370G

SPR378G

SPR

403

3/16 in. (4,7mm)

7/32 in. (5,4mm)

1/4 in. (6,25mm)

7/32 in. (5,4mm)

7/32 in. (5,4mm)

3/16 in. (4,7mm)

7/32 in. (5,4mm)

7/32 in. (5,4mm)

7/32 in. (5,4mm)

McCulloch saw chain is a precision manufactured

cutting

attachment and requires regular inspection and care to main-

tain peak

cutting

efficiency. Touch up sharpening may be

required once or twice

during

a day's

wood

cutting. In some

areas

where sand or other

abrasives

have become embedded

in the bark of trees, cutter

teeth

dull

more rapidly and more

frequent sharpening may be required.

WARNING: Always wear protective gloves when handling

chain.

NOTE:

In addition, all saw chains should be periodically

machine sharpened to maintain correct

cutting

angles.

1.

Chain can be sharpened on saw by placing the bar in a

bench

vise

while resting the saw on the bench.

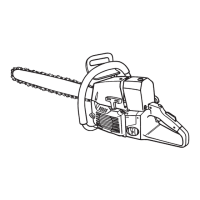

2.

Use a

round

file

of the proper

size

for all PM, SM,

SPR

and

PGR

chains, and a

file

guide marked for the correct

filing

angle.

Refer

to the

file

size

table and the

filing

angles

illustrated for the types of chain. If

filing

without

the

file

guide, place

file

on

tooth

to be sharpened

with

one-

seventh

of the

file

above the top plate edge. Avoid

holding

the

file

too low or too

high

and causing a

"hook"

or ari

"backslope."

Always

file

toward the outside of the chain.rr

3.

Hold

the

file

at the correct top plate

filing

angle, apply

pressure

against the face of the

tooth,

and push the

file

toward the outside of the

tooth.

Release

pressure on the

cutting

edge on the

return

stroke.®

4.

Repeat

sharpening stroke

until

tooth

is

sharp.

Drop

file

into

gullet

and clean out

with

a few

light

strokes. Do not

touch

cutting

edge of the

tooth.

5.

Sharpen all

teeth

on one side of chain before sharpening

teeth

on the other side. Use same number of strokes on

each

tooth

to help keep all

teeth

the same length.

Hold

the

file

level for all PM chains except PM 378.

20

Loading...

Loading...