GUIDE

BAR MAINTENANCE

Bar

wear: Turn bar over frequently (at regular intervals) to

ensure

even wear on top and

bottom

of bar.

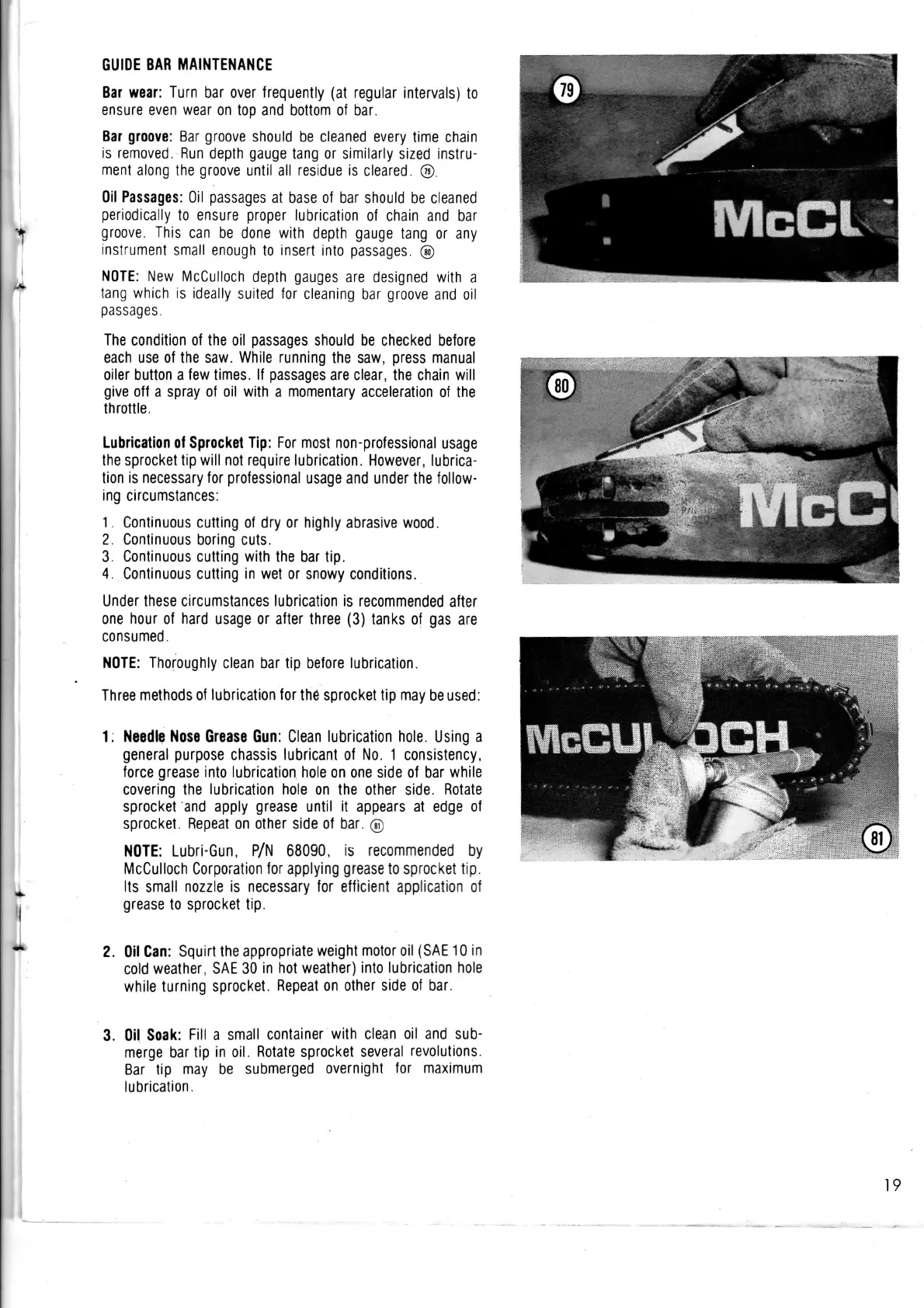

Bar

groove: Bar groove should be cleaned every

time

chain

is

removed. Run

depth

gauge tang or similarly sized instru-

ment along the groove

until

all residue is cleared. ®.

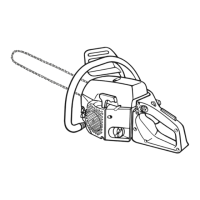

Oil

Passages:

Oil

passages

at

base

of bar should be cleaned

periodically to ensure proper lubrication of chain and bar

groove.

This

can be done

with

depth

gauge tang or any

instrument small enough to insert

into

passages.

®

NOTE:

New McCulloch

depth

gauges are designed

with

a

tang which is ideally suited for cleaning bar groove and oil

passages.

The

condition

of the oil

passages

should be checked before

each

use of the saw. While running the saw,

press

manual

oiler

button

a few times. If

passages

are clear, the chain

will

give off a spray of oil

with

a momentary acceleration of the

throttle.

Lubrication

of Sprocket Tip: For most non-professional usage

the sprocket tip

will

not require lubrication. However, lubrica-

tion

is

necessary

for professional usage and under the

follow-

ing circumstances:

1.

Continuous

cutting

of dry or highly abrasive wood.

2.

Continuous

boring

cuts.

3.

Continuous

cutting

with

the bar tip.

4.

Continuous

cutting

in wet or snowy conditions.

Under these circumstances lubrication is recommended after

one hour of hard usage or after three (3) tanks of gas are

consumed.

NOTE:

Thoroughly clean bar tip before lubrication.

Three

methods of lubrication for the sprocket tip may be

used:

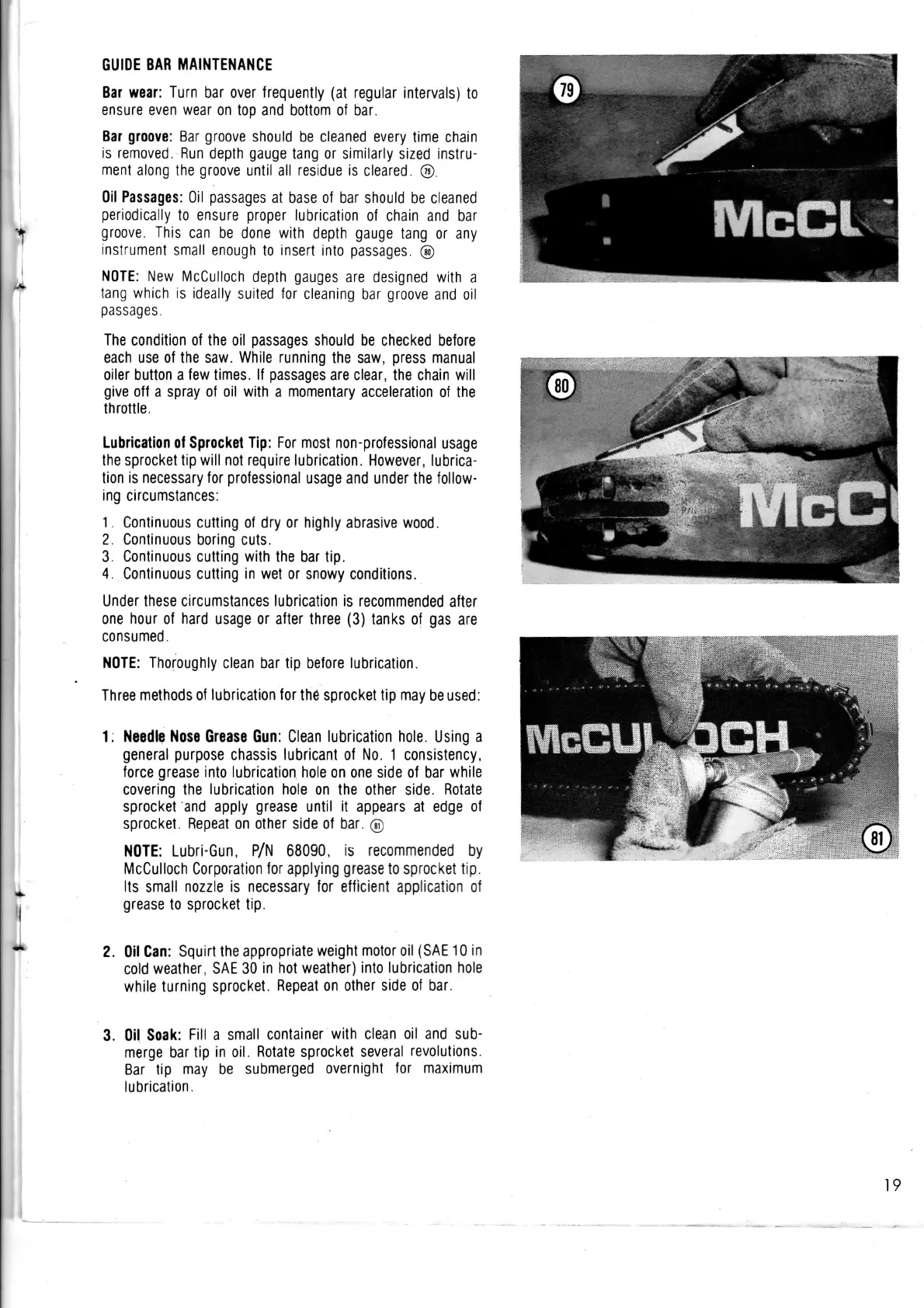

1:

Needle Nose

Grease

Gun:

Clean

lubrication hole. Using a

general

purpose

chassis

lubricant of No. 1 consistency,

force grease

into

lubrication hole on one side of bar while

covering the lubrication hole on the other side. Rotate

sprocket and apply grease

until

it appears at edge of

sprocket. Repeat on other side of bar. ®

NOTE:

Lubri-Gun, P/N 68090, is recommended by

McCulloch Corporation for applying grease to sprocket tip.

Its

small nozzle is

necessary

for efficient application of

grease

to sprocket tip.

2.

Oil

Can:

Squirt the appropriate weight

motor

oil

(SAE

10 in

cold weather,

SAE

30 in hot weather)

into

lubrication hole

while

turning

sprocket. Repeat on other side of bar.

3.

Oil Soak:

Fill

a small container

with

clean oil and sub-

merge bar tip in oil. Rotate sprocket

several

revolutions.

Bar

tip may be submerged overnight for maximum

lubrication.

Loading...

Loading...