8

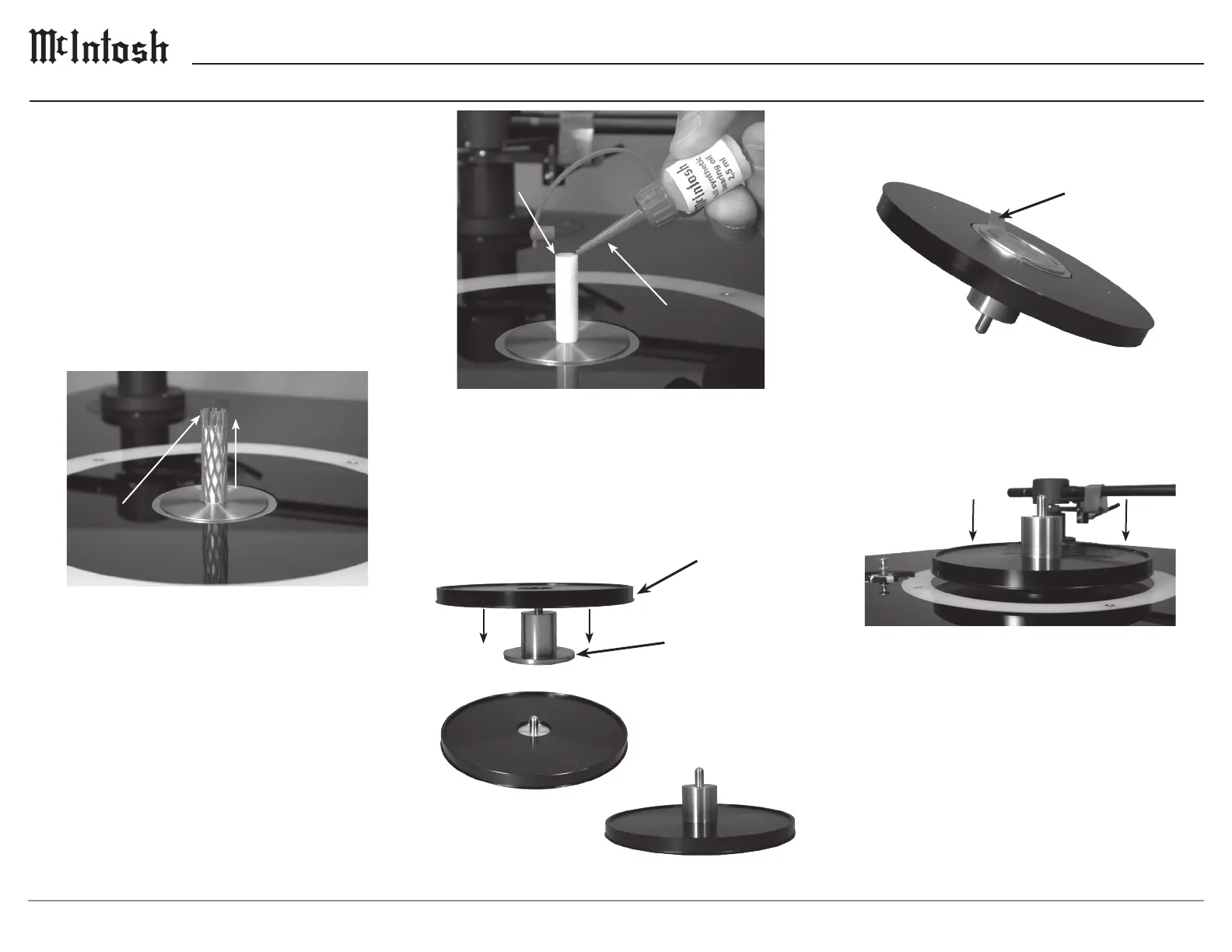

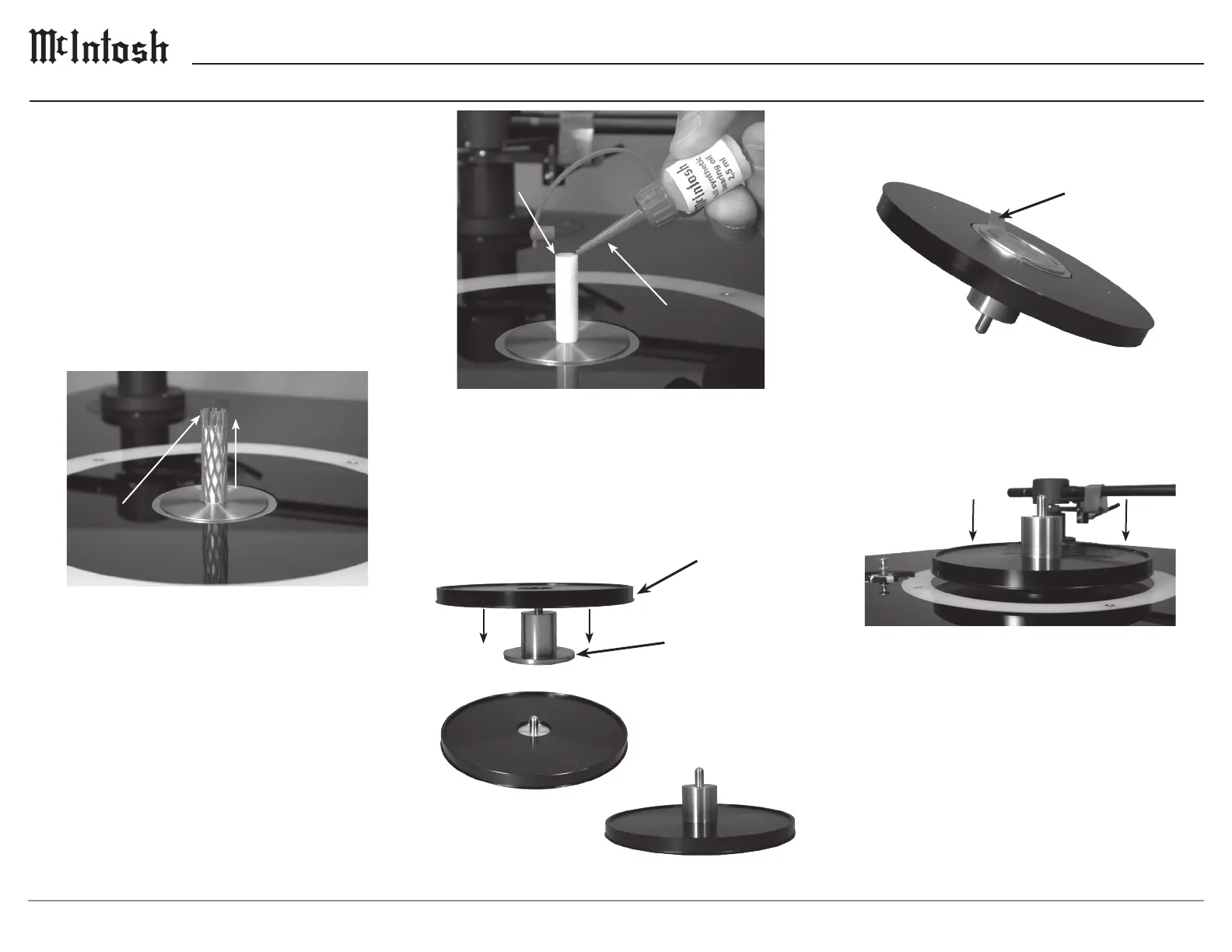

5. Invert the just assembled spindle/inner platter and

remove the protective film from the bottom. Refer

to figure 6.

6. Very carefully lower the assembled spindle/inner

platter onto the Ceramic Vertical Bearing Shaft,

keeping the platter parallel with the top surface of

the Turntable. Refer to figure 7.

Note: The Ceramic Vertical Bearing Shaft of the McIntosh

MT5 Precision Turntable is very durable in actual

use, however it can be damaged during the assembly

process if care is not taken.

7. Using the supplied cloth gloves, place the belt

onto the circumference of the inner platter and

then onto the pulley of the motor. Rotate the inner

platter by hand while seating the belt into it. Refer

to figure 8.

3. Locate the Center Spindle and Inner Platter.

4. Place the bottom of the Center Spindle on the

prepared flat surface. Line up the center opening

of the Inner Platter with the Center Spindle and

carefully lower the Inner Platter onto the Center

Spindle. Refer to figures 3, 4 and 5.

Place the Turntable in the location where it will

be used. Please keep in mind; the turntable should

be the greatest possible distance from the system

loudspeakers to reduce the chance of acoustic

feedback. To minimize the possibility of the cartridge

stylus jumping record grooves, place the turntable

on a mechanically stable surface such as wall shelv

-

ing anchored to wall studs. Perform the following

assembly steps:

Note: It is recommended the installation and adjustment of

the McIntosh MT5 Precision Turntable be performed

by the Professionals at your McIntosh Dealer.

1. Remove the protective mesh from the Turntable

Vertical Bearing Ceramic Shaft. Refer to figure 1.

2. Locate the supplied Turntable Bearing Oil and

place two small drops of Oil on the top sides of

the Ceramic Vertical Bearing Shaft. Refer to

figure 2.

Assembling the Turntable

Ceramic

Vert ical

Bearing

Shaft

Supplied

Oil

Figure 2

Figure 6

Remove

Protective

Film

Figure 1

Remove

Protective

Mesh

Figure 4

Figure 5

Inner Platter

Center Spindle

Figure 3

Figure 7

Loading...

Loading...