Section 5 - Maintenance

Page 74 90-899883272 MARCH 2008

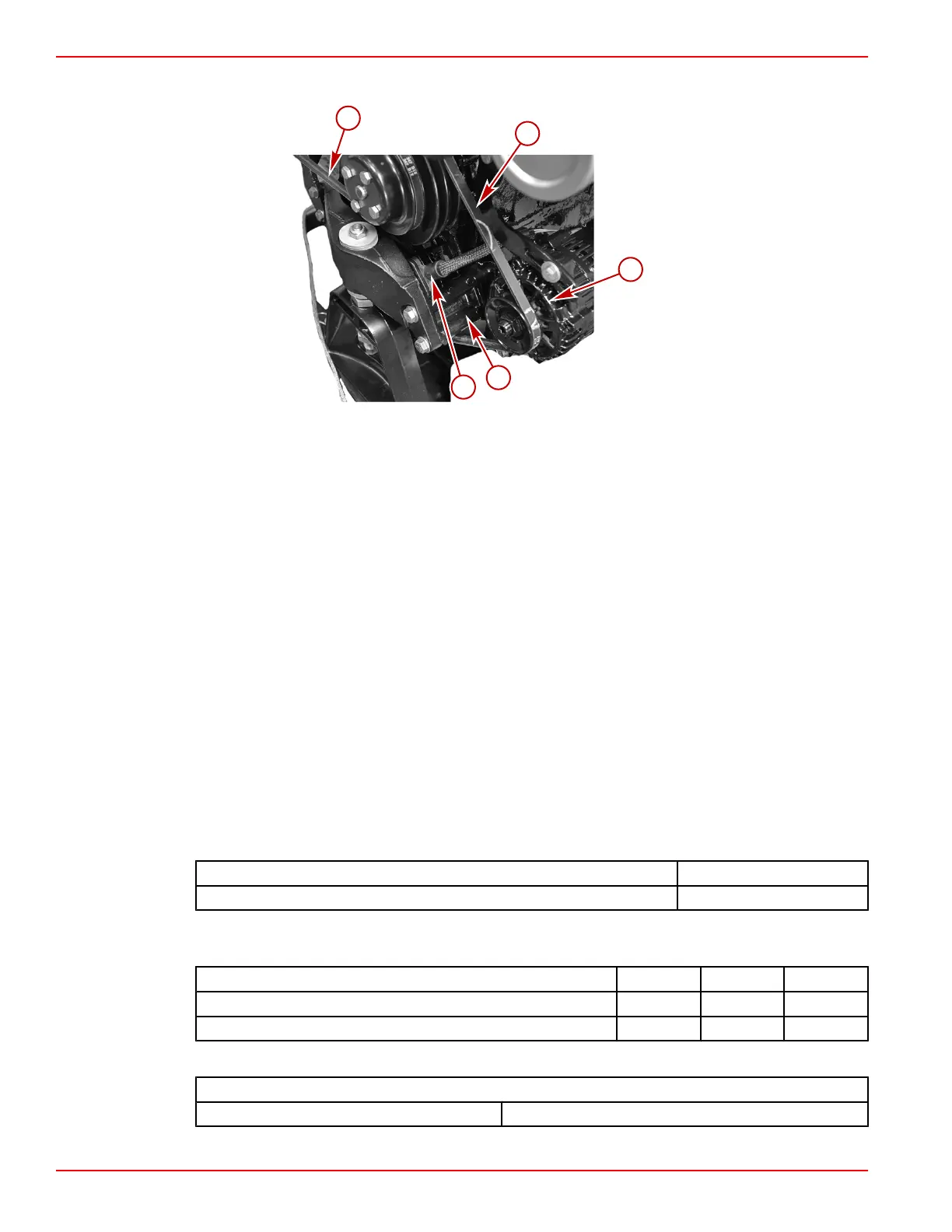

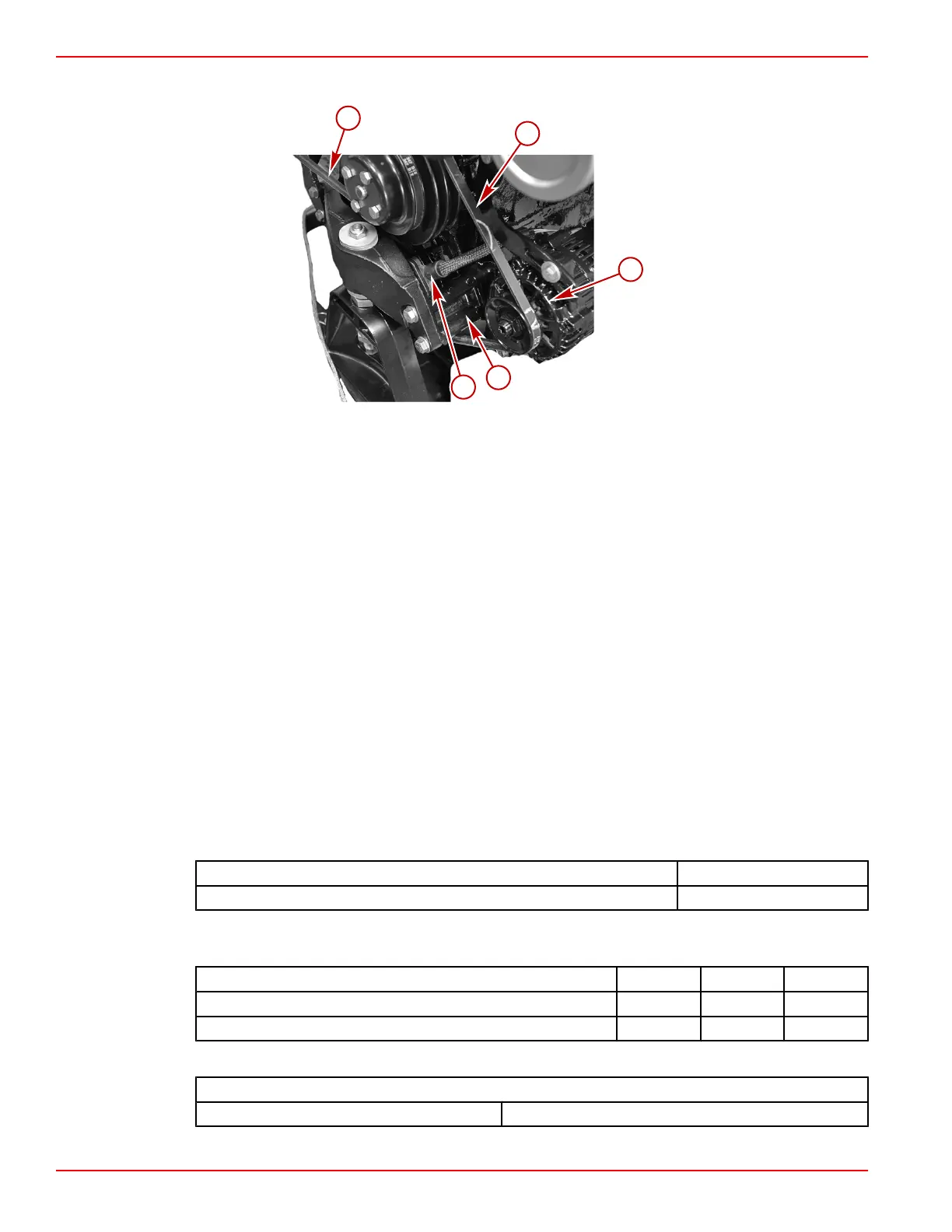

Replacing Belts on Front Mount Models

a - Power steering belt

b - Alternator belt

c - Alternator

d - Spacer block

e - Crank position sensor

POWER STEERING PUMP DRIVE BELT

1. Loosen power steering pump attaching bolts and mounting bolts.

2. Pivot power steering pump toward engine, as required, until belt can be removed.

3. Install new drive belt on pulleys. Adjust tension.

ALTERNATOR BELT

1. Remove the power steering belt, if equipped.

2. Remove the two screws and washers from the front engine mount bracket assembly

on the port side.

3. Remove the spacer block between the bracket assembly and the engine block. You

may need to tap gently on the spacer.

4. Loosen the alternator. Remove and replace the alternator belt.

5. Replace the spacer block between the bracket assembly and the engine block. Install

the two screws using the washers removed previously.

6. Adjust the crank position sensor so the gap between the sensor and the flywheel meets

the following specification.

Description Specification

Crankshaft position sensor air gap 0.040 in.

7. Tighten the two spacer block bolts. If necessary, you can loosen the crankshaft position

sensor bolts to move the sensor into position. Tighten all bolts to specification.

Description

Nm lb‑in. lb‑ft

Spacer block bolts 68 – 50

Crankshaft position sensor bolts 2 18 –

8. Install power steering belt, if equipped. Adjust the tension of both drive belts.

Description

Deflection 6 mm ( 1/4 in.)

Loading...

Loading...