Section 5 - Maintenance

90-899883210 APRIL 2008 Page 29

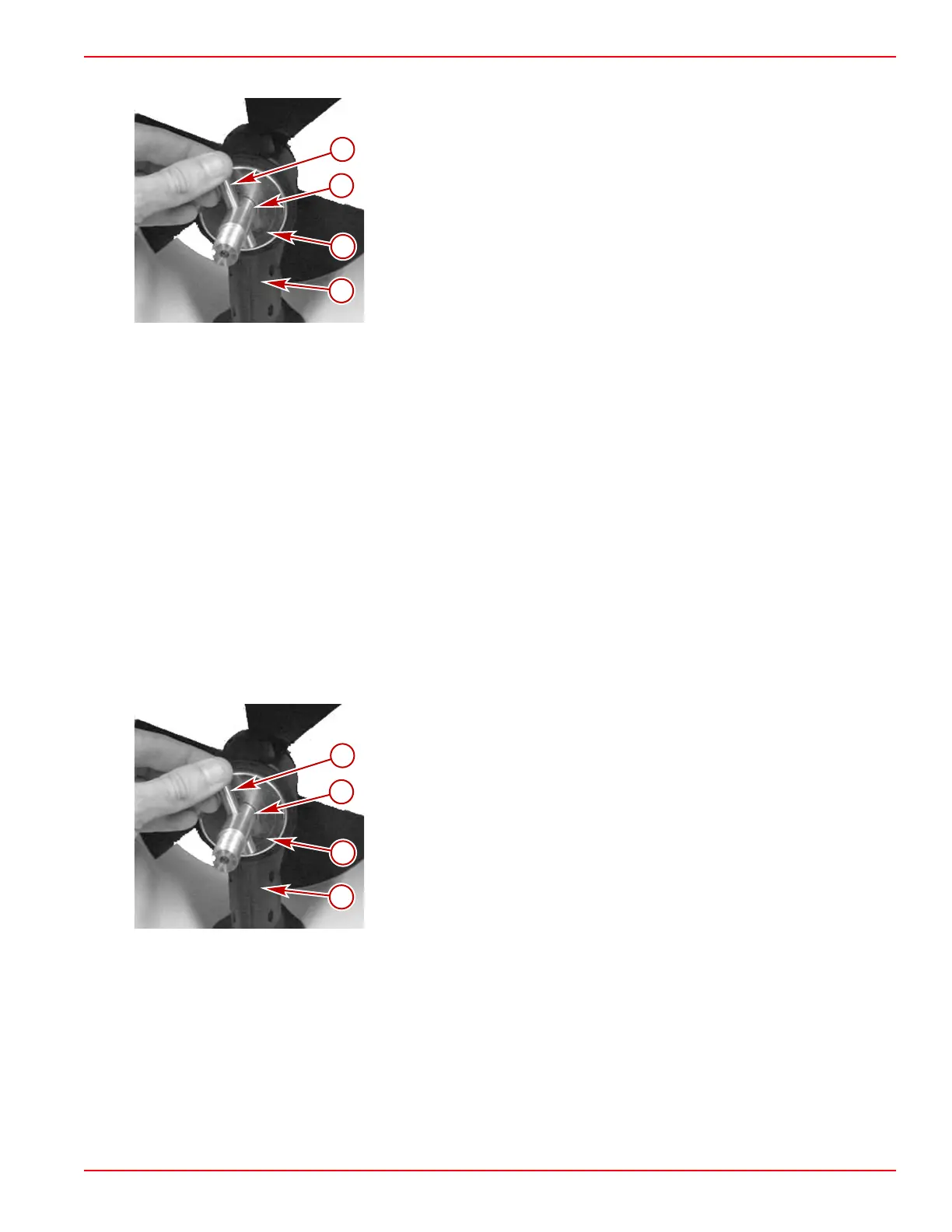

5. Remove the propeller pin from the propeller shaft.

a - Propeller pin

b - Propeller shaft

c - Stainless steel seal cover

d - Drive leg

Thruster Leg Maintenance

The composite drive leg is lubricated for life. The oil does not need to be changed.

The drive leg must not be disassembled, even partially. Any disassembly requires the entire leg to be

replaced.

1. Clean and inspect the drive legs for damage. Inspect the propeller shaft for pitting or wear. Do not use

solvents that might damage drive leg seals. If damage is found, replace the entire leg.

2. Inspect the drive leg oil seals. If the drive leg oil seals are worn, replace the entire drive leg.

3. Paint the leg and propellers with antifouling paint. Make sure that the leg and propeller are clean and

primer has been used.

4. Cover the drive shaft and the stainless steel oil seal cover with silicone grease before fitting the

propeller(s) to prevent calcium build‑up. This should be done on an annual basis after cleaning the

outside of the leg.

Installation

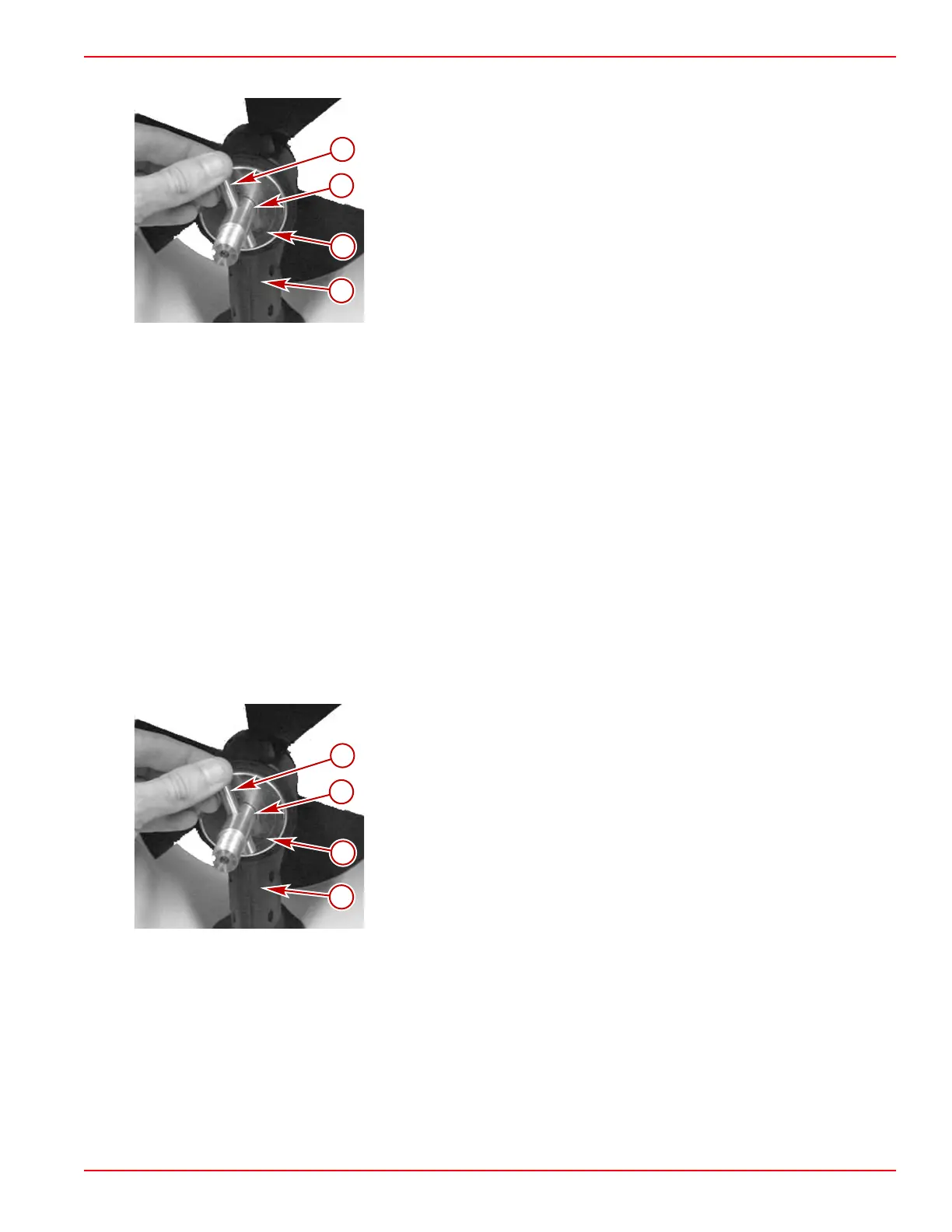

1. Liberally coat the propeller shaft and seals with grease. Cover the stainless steel oil seal cover with

silicone grease, and install with the formed lip of the cover facing the drive leg.

2. Install the propeller pin or pins. Each pin should be centered on the propeller shaft.

a - Propeller pin

b - Propeller shaft

c - Stainless steel seal cover

d - Drive leg

Loading...

Loading...