Section 5 - Maintenance

90-899883179 OCTOBER 2007 Page 47

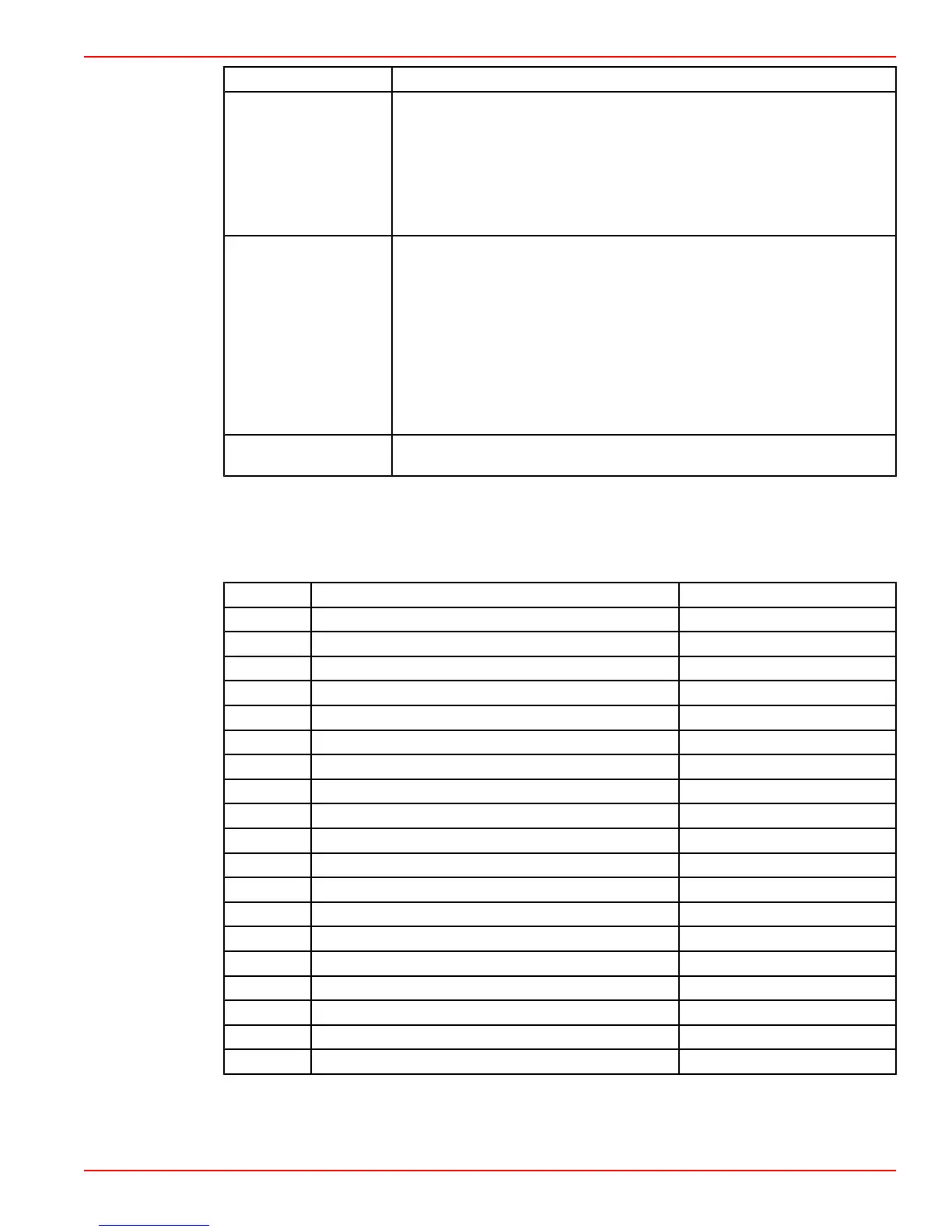

Task Interval Maintenance to Be Performed

Every 200 hours or 3

years

• Inspect the U‑joints, the splines, and the bellows. Check the clamps.

• Check the engine alignment.

• Lubricate the U‑joint splines and cross bearing, if equipped with grease

fittings.

• Lubricate the gimbal bearing and the engine coupler.

NOTE: Lubricate the engine coupler every 50 hours if operated at idle for

prolonged periods of time.

Every 300 hours or 3

years

• Check the engine mounts for tightness and tighten to specifications if

necessary.

• Check the electrical system for loose, damaged, or corroded fasteners.

• Check the cooling system and the exhaust system hose clamps for tightness.

Inspect both systems for damage or leaks.

• Disassemble and inspect the seawater pump and replace worn components.

• Clean the seawater section of the closed‑cooling system. Clean, inspect,

and test the pressure cap.

• Inspect the exhaust system components. If the package was equipped with

water shutters (flapper valves), verify that they are not missing or worn.

Every 5 years

• Replace the coolant/anitifreeze. Replace every two years if not using

extended‑life coolant/antifreeze.

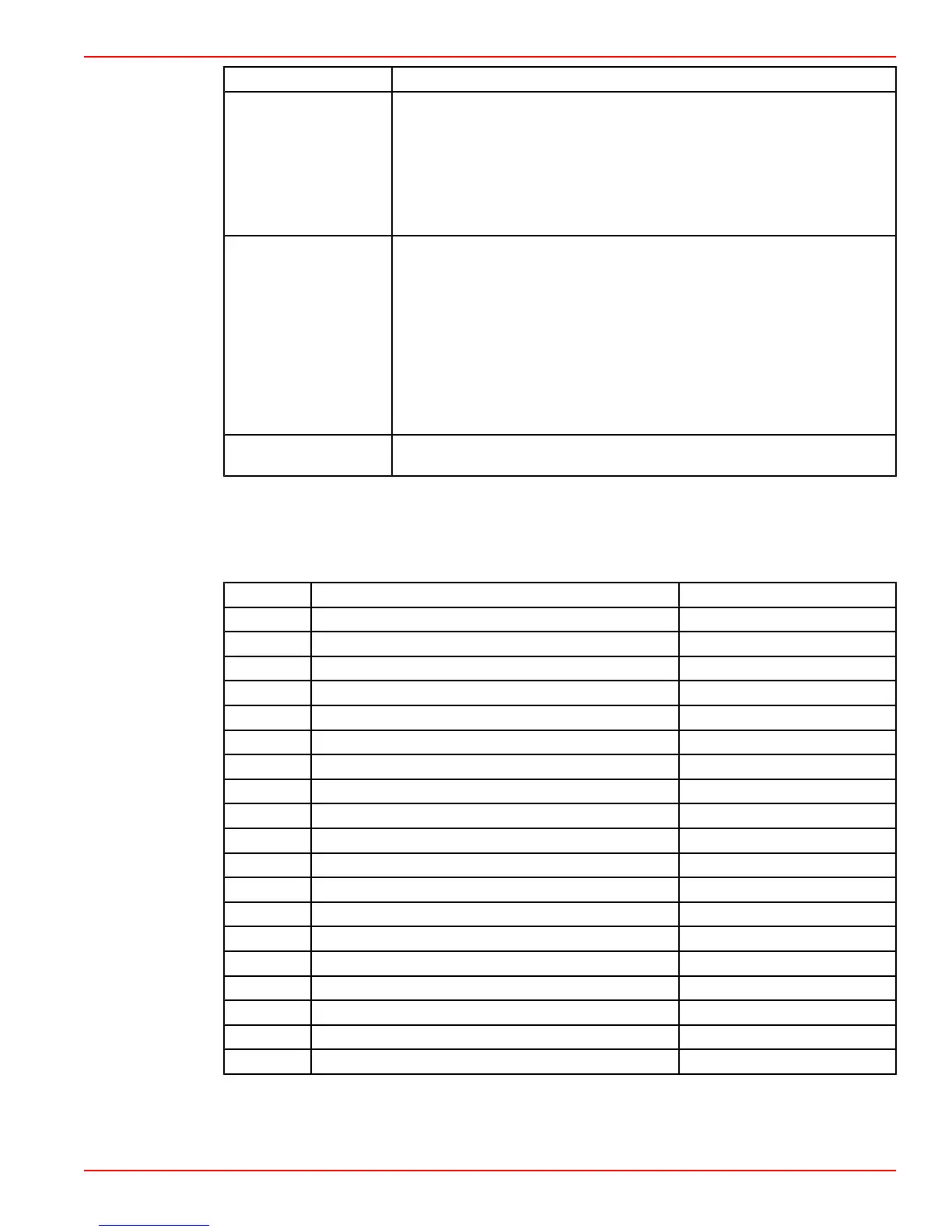

Maintenance Log

Record all maintenance performed on your power package here. Be sure to save all work

orders and receipts.

Date Maintenance Performed Engine Hours

Loading...

Loading...