14 Meritor Differential Carrier 17X

2 Maintenance

Introduction

In order to ensure reliable and efficient differential unit operation,

maintenance intervals, use of lubricants and correct procedures

specified by the manufacturer should be strictly observed (refer to

Lubrication Maintenance Manual no.1). For further information

contact the manufacturer’s engineering department or refer to the

Meritor Web site at www.meritor.com

Spare parts

Use original Meritor spare parts only.

Differential removal and installation

1. If the vehicle is loaded, unload the rear axle before removing

the differential.

2. Place the vehicle on level ground and chock the front wheels.

3. Rest the rear axle on two suitably strong axle stands.

4. Remove the drain plug from the rear axle bottom end and drain

lubricant.

5. Engage differential lock before air pressure falls below 2.8 bars

6. Remove axle shaft mounting screws and washers.

7. Remove axle shafts.

8. Remove propeller shaft.

9. Disconnect compressed air lines and differential lock sensor

switch coupling.

10.Remove differential carrier to rear axle housing fastening

screws (leave two screws in place to prevent the differential

from falling).

11.Safely support carrier assembly with suitable lifting tool to aid

removal. Remove plastic protective plugs fitted to the

extraction screw holes. Fit extractor screws. Remove final 2

carrier screws to withdraw carrier assembly. Mount the carrier

assembly in a suitable fixture and remove the differential lock

assembly as described in Section 5 Differential Lock

Removal.

Checking rear axle housing

Check rear axle alignment to prevent possible distortion from

causing abnormal stress, noise and pneumatic consumption.

Installation - Reassembly

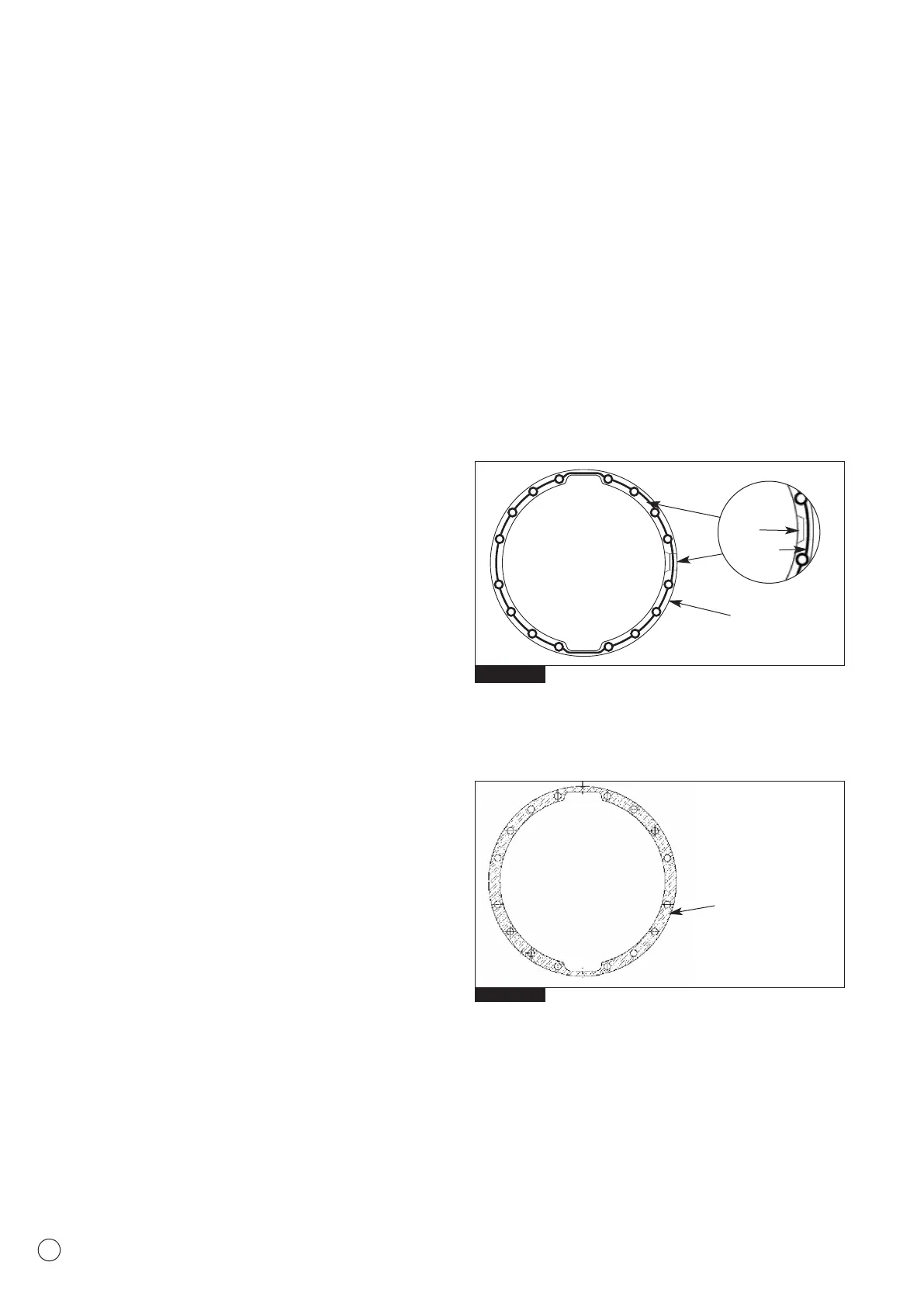

1. Clean mounting faces and threads thoroughly. Apply a

continuous bead of sealant DC 7091 to the rear axle mounting

face (Fig.2.1a) Ensure the continuous bead of sealant is applied

around the slots in the mounting face to achieve correct

sealing. DO NOT apply the sealant over the slots (Fig 2.1a).

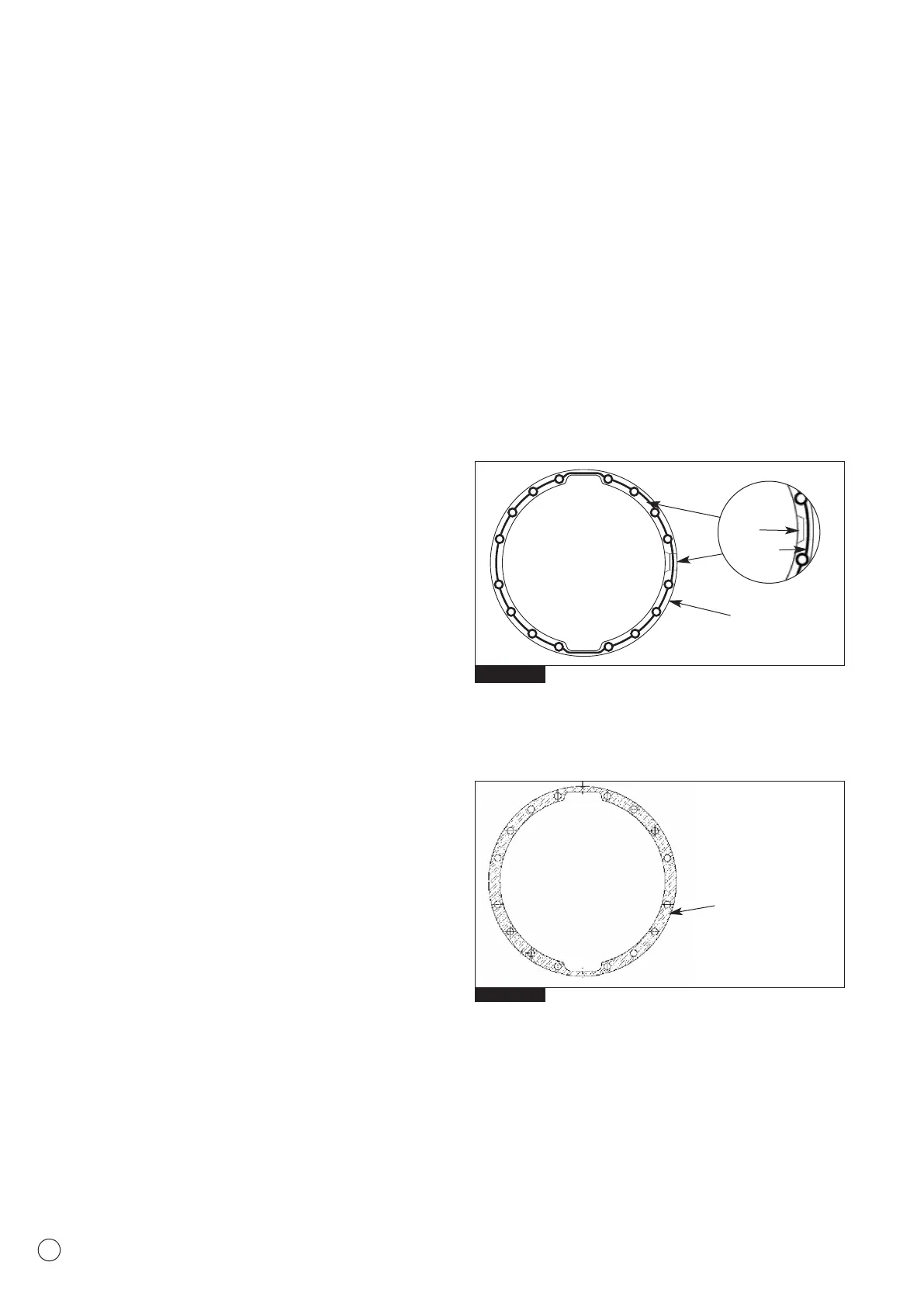

2. Apply sealant (Loctite 510 or 549) to the complete surface of

the joint gasket (Fig 2.1b.)

NOTE: The carrier to housing assembly must be completed within

15 minutes of applying the sealant to the mating surfaces.

Reverse the removal operation sequence and torque fastening

screws/nuts and drain plug to the specifications detailed in

Section 6 Tightening Torques & Lubrication.

Fig. 2.1a

Fig. 2.1b

Continuous bead

of sealant

DC7091

Apply sealant

(Loctite 510 or 549)

to the complete surface

Slot

Sealant

Loading...

Loading...