23

Meritor Differential Carrier 17X

2 Maintenance

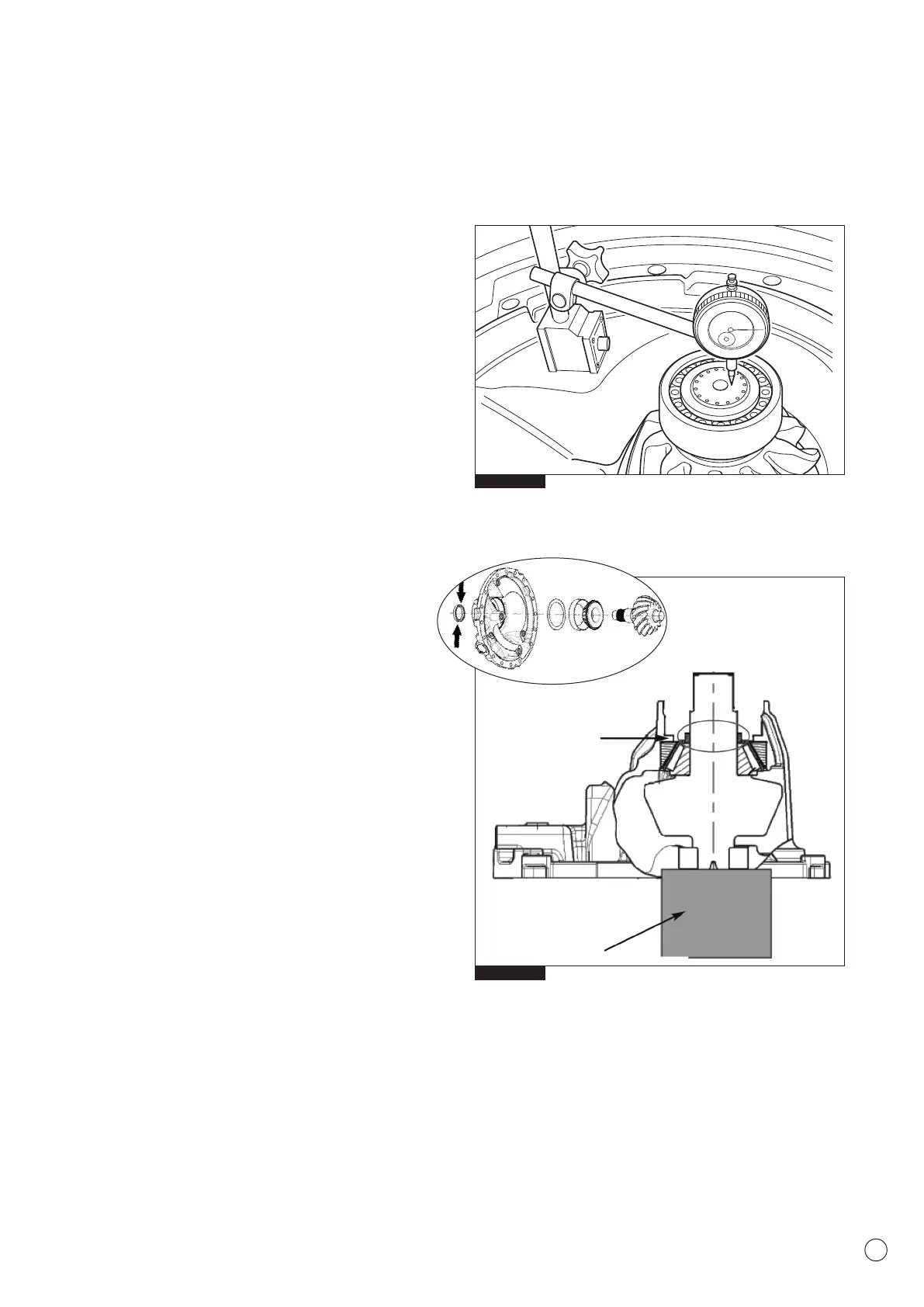

11. Set a DTI (Dial Test Indicator) against the head of the pinion

spigot nose and set to “0” (Fig.2.26).

12. Move the pinion shaft and measure the axial movement

recorded on the DTI. Record the measurement Y

13. Using the dimension of the master spacer X and the DTI

reading Y, calculate the correct spacer value required

following the calculation;

X - Y- 0.08mm (coefficient factor) = Spacer dimension

Example:

Master Spacer X = 15.155mm

Pinion Axial Movement Y = 0.55mm

Coefficient Factor = 0.08mm

15.155 - 0.55 - 0.08 = Calculated Spacer Value 14.525mm

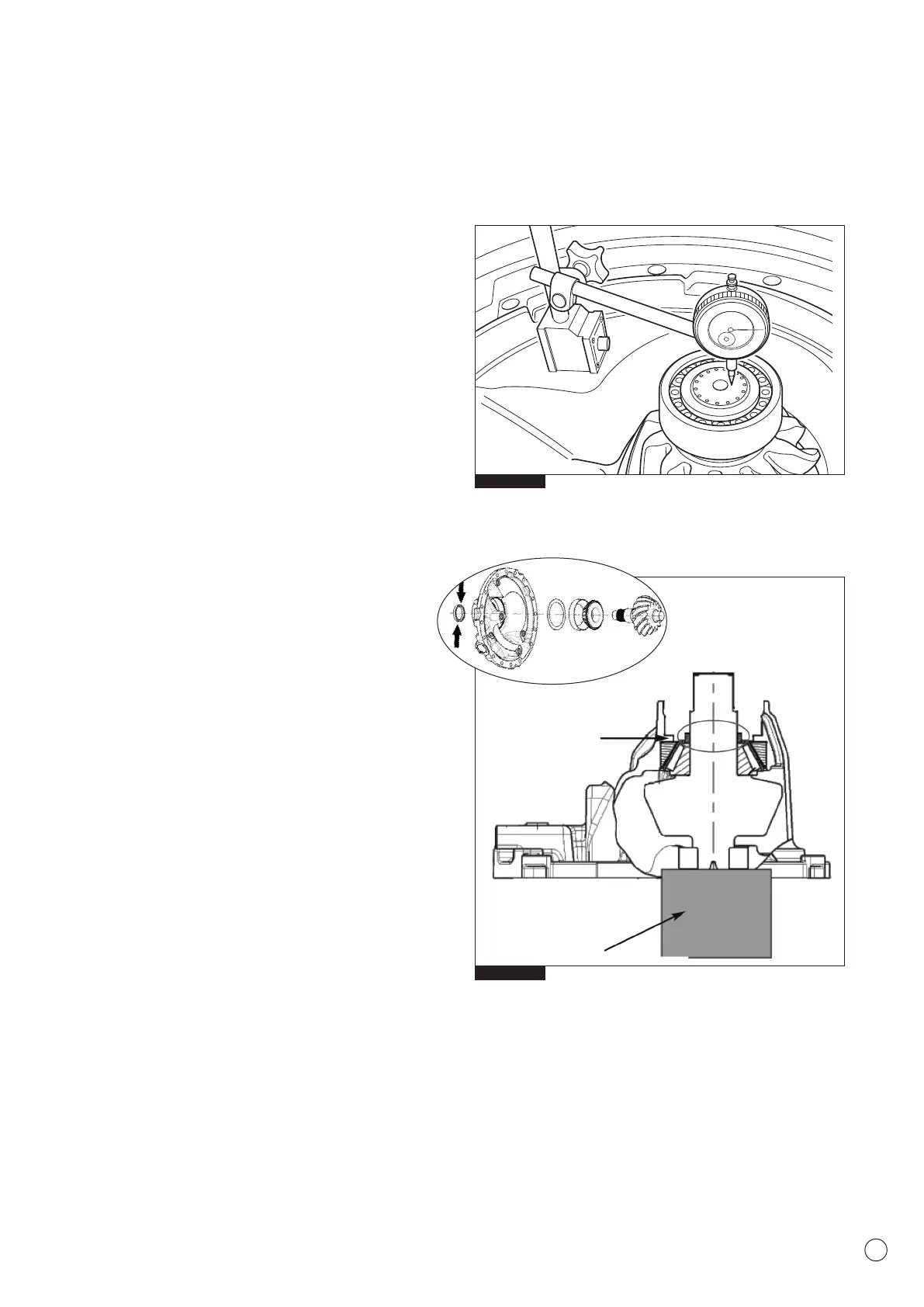

NOTE: The spacers control the preload adjustment of the drive

pinion bearings. Always select a spacer as close as possible to

the value calculated.

14. Remove the pinion nut and flange.

15. Remove the outer bearing cone and master spacer.

16. Position the calculated spacer identified above to provide the

correct bearing pinion preload (Fig.2.27) and continue

assembling the carrier.

17. Using a suitable service tool (CT45), firmly press the outer

bearing cone of the pinion shaft once more against the

spacer/s (Fig.2.28) using a press load of 6 - 8 ton. Rotate the

pinion by hand to seat the bearings.

Fig. 2.26

Fig. 2.27

Wooden Block

Pinion Head Support

Calculated

Spacer

Loading...

Loading...