51

Meritor Differential Carrier 17X

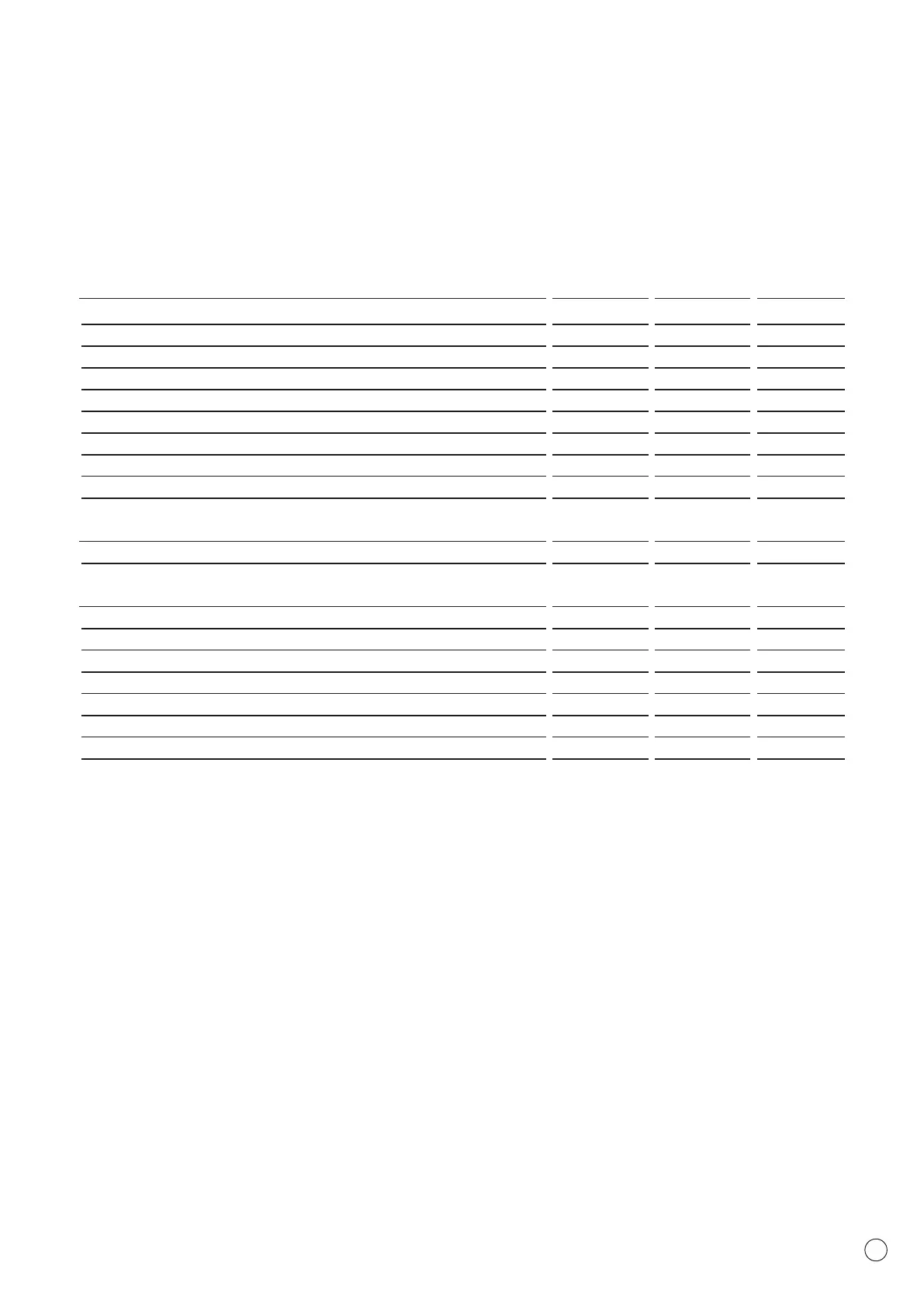

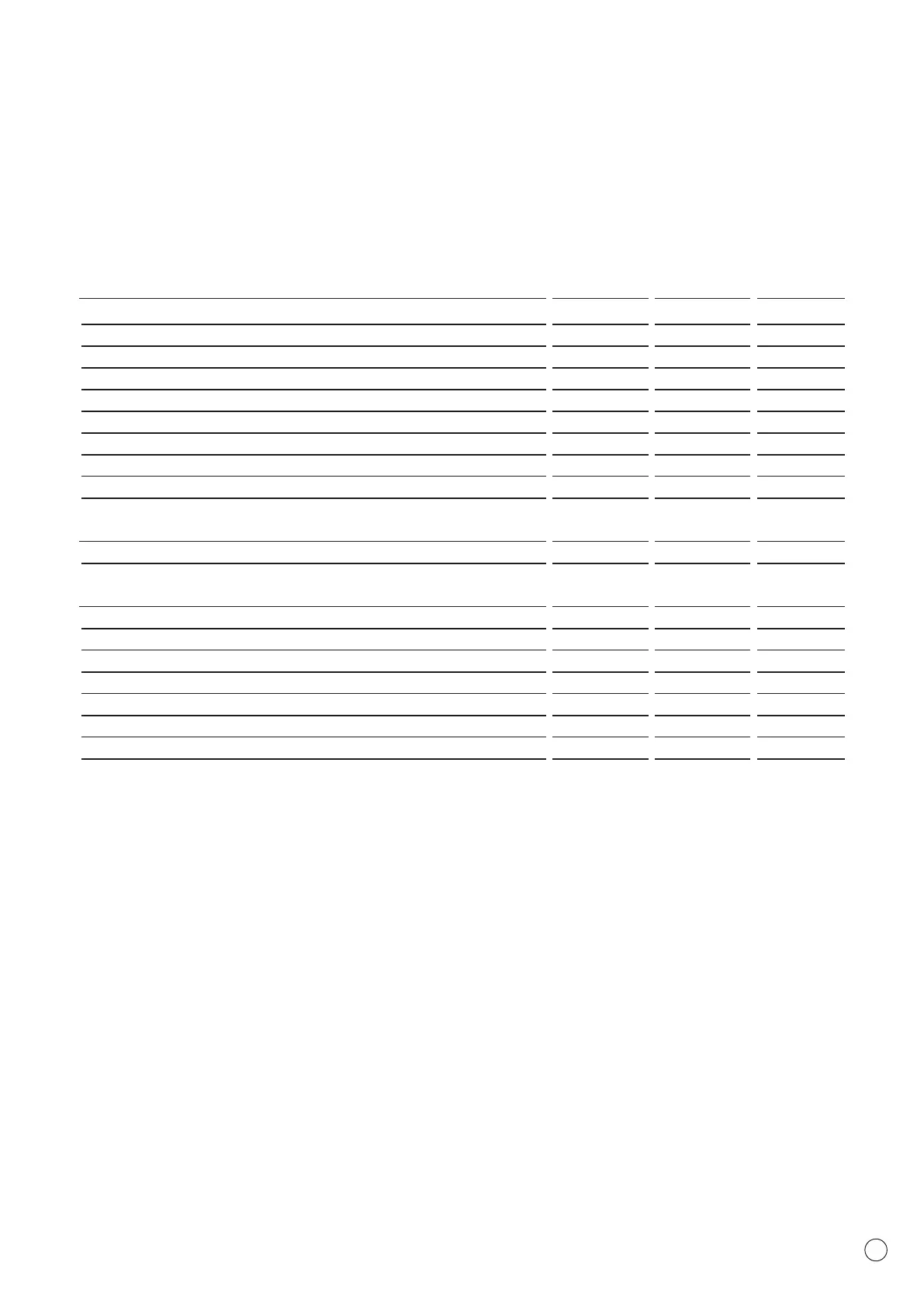

6 Tightening Torque Values & Lubrication

T

ightening Torque Table

Description

Nm Degrees Kgm

1 Drive pinion nut – M45X2 1350÷1670 135÷167

2 Lock nut sensor switch - M16X1 [**] 35÷45 3.5÷4.5

3 Sensor hole plug (if fitted) - M16X1 [**] 60÷75 6 ÷ 7,5

4 Cover capscrews - M6X1 10÷12 1.0÷1.2

5 Diff. bearing cap.capscrews M22X2.5 [*] (torque + angle procedure) 200 90°÷105° 20

(torque only) 650÷810 65÷81

6 Adjusting ring lock plate capscrew M6X1 10÷12 1÷1.2

7 Stud into cast housing M16x1.5 (if fitted) 63÷77 6.3 ÷ 7.7

Stud into fabricated housing M16x1.5 (if fitted) [***] 63÷77 6.3 ÷ 7.7

8 Carrier assembly to cast housing

screws/stud nut M16X1.5 [*] (torque + angle procedure) 100 105°÷115° 10

(torque only) 260÷280 26÷28

8 Carrier assembly to fabricated housing [***]

screws/stud nut M16X2 [*] (torque + angle procedure) 100 80°÷90° 10

(torque only) 250÷440 25÷44

9 Oil filler plug cast housing M24X1.5 [***] 80 ± 20 8 ± 2

Oil filler plug fabricated housing M24X1.5 [***] min.47 min 4.7

10 Oil drain plug cast housing M24X1.5 [***] 80 ± 20 8 ± 2

Oil drain plug fabricated housing M24X1.5 [***] min.47 min 4.7

11 Breather cast housing screw M12X1.5 25 ÷ 35 2.5÷3.5

Breather fabricated housing M12X1 15 ÷ 20 1.5÷2

* Preferred method: Torque + angle.

** Apply sealant Loctite 573 to the threads and carefully screw into the differential casing approx. 3 threads.

*** Apply sealant Loctite 573 to the threads if removed.

Torque Values

Lubrication

Oil Specification Oil Capacity

Hypoid Gear Oil MS 17X = 12.5 ± 0.5 Litres

• S.A.E. J2360 - GL5 - tested and approved (see also TP0460)

Loading...

Loading...