25

Meritor Differential Carrier 18X

2 Maintenance

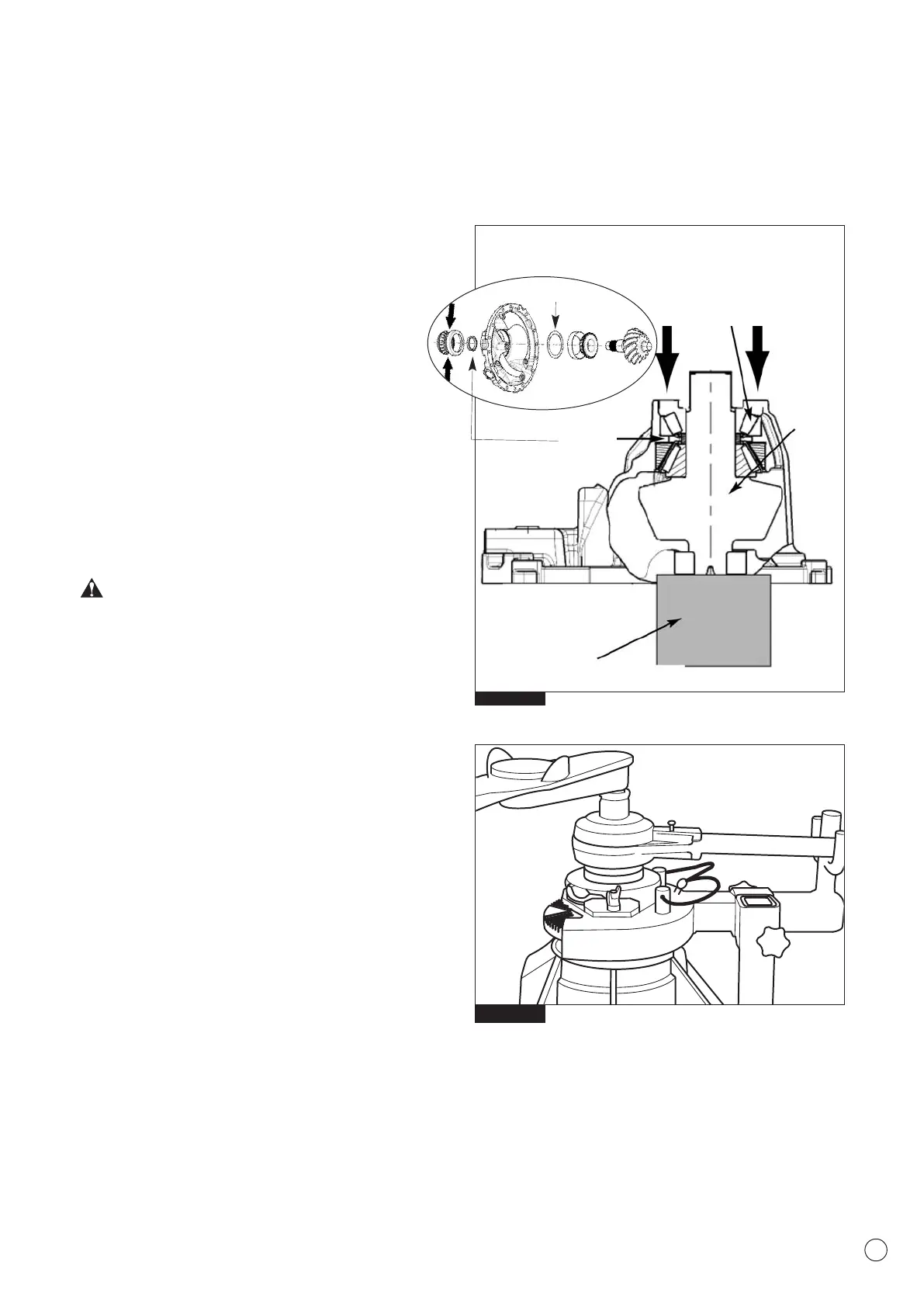

19. Using a suitable service tool (MST4804), firmly press the

outer bearing cone of the pinion shaft once more against the

spacer/s (Fig.2.32) using a press load of 6 - 8 ton. Rotate the

pinion by hand to seat the bearings.

NOTE: If a press is not available proceed to point 20 and fit the

flange.

CAUTION:

When using a press to fit the outer bearing cone on the

pinion always support the pinion head with a suitable block

of wood (Fig. 2.32). Failure to do this could result in damage

to the carrier casting or drive gear assembly.

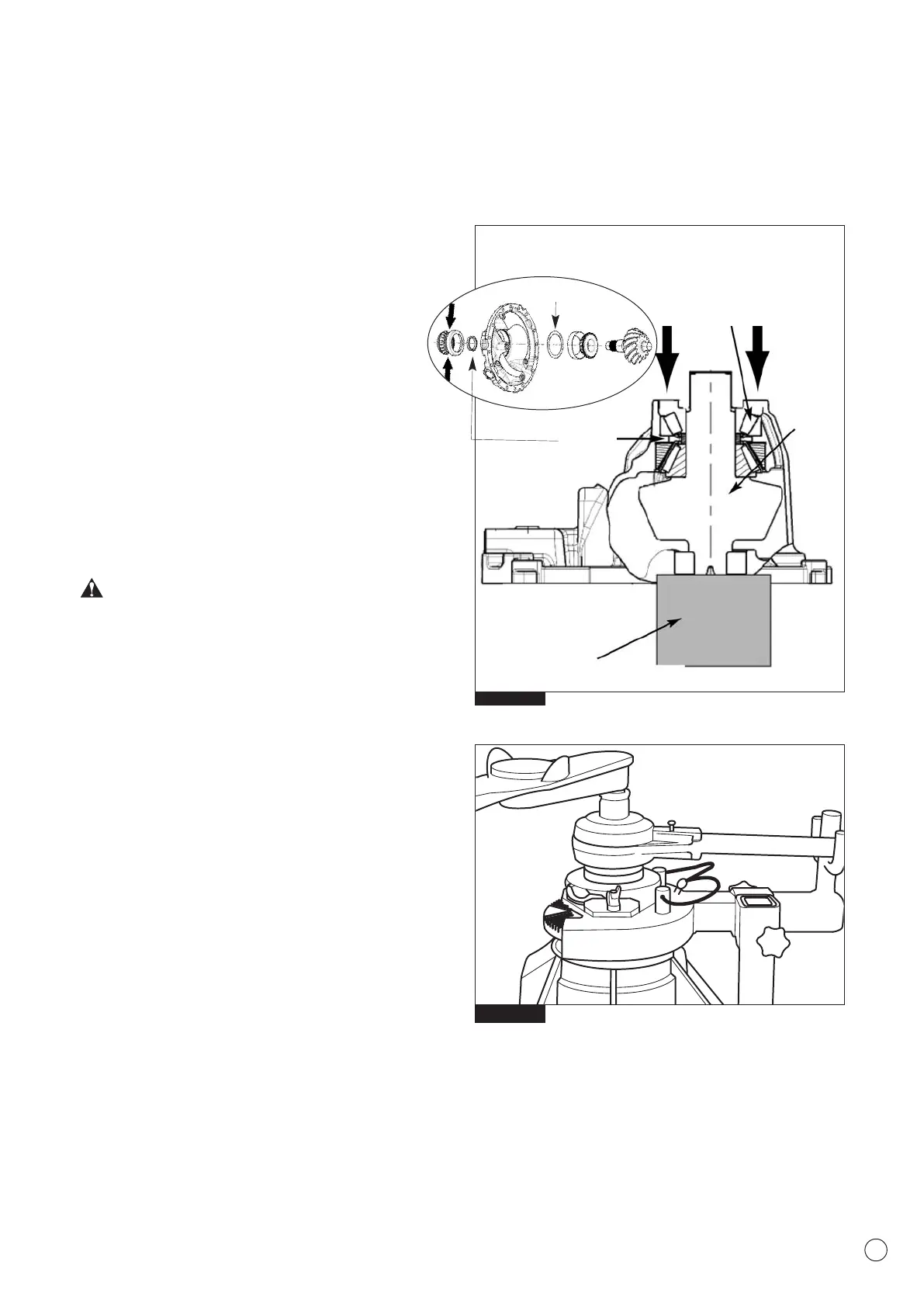

20. Fit the flange and tighten the pinion nut to a torque value of

2000 - 2500Nm.

NOTE: The flange must be fully seated against the outer pinion

bearing before the nut is tightened to the torque specification.

The flange must be held with a suitable tool (MST4400-CT13) to

tighten the nut and a torque multiplier will be required to achieve

the correct torque value of 2000 - 2500 Nm. (Fig.2.33)

Fig. 2.32

Spacer

Outer

Bearing Cone

Wooden Block

Pinion Head Support

Pinion

Fig. 2.33

Shims

Loading...

Loading...