20

ENGLISH

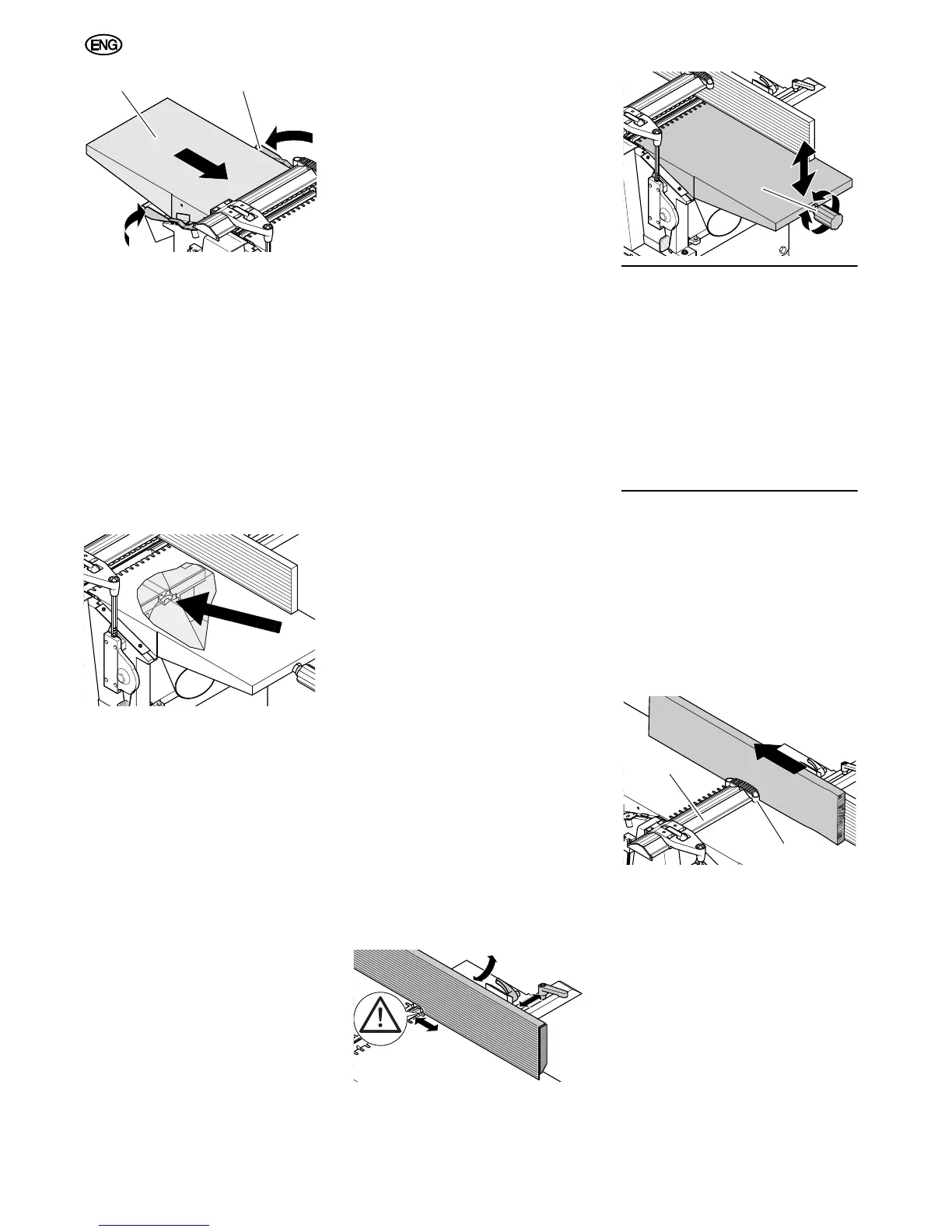

4. Secure outfeed table (54) with both

lock levers (55).

5. Crank thicknesser bed up to

120 mm height.

6. Place dust collector connector (this

is not the chip chute mentioned in

step 1!) below the infeed table into

the machine. Observe correct posi-

tion of the dust collector connector:

− suction port points outwards;

− slide dust collector connector in

until the point of intersection of

shaft and axis below the infeed

table (arrow) is exactly above the

matching seat of the dust collec-

tor connector.

7. Crank the thicknesser bed carefully

up to secure the dust collector con-

nector in position.

8. Connect a suitable dust collector to

the suction port of the dust collector

connector.

A

Danger!

Some types of wood dust (e.g. oack,

ash) may cause cancer when inhaled:

When working indoors work only with a

suitable dust collector connected to the

machine:

− Fitting the outer diameter of the

suction port (100 mm);

− air flow volume ≥ 550 m

3

/h;

− vacuum at suction port of

machine ≥740 Pa;

− air speed at suction port of

machine ≥20 m/s;

A

Caution!

Operation without a dust collector is only

possible:

− Outdoors;

− if only a minimum of chips is gen-

erated (with narrow stock and lit-

tle chip removal);

− with dust respirator.

6.2 Surface Planing and

Edge Jointing

A

Danger!

− Risk of serious personal injury by

rotating cutterblock! Always

cover the part of the cutterblock

that is not covered by the work

piece with the cutterblock guard

extrusion. Adjust the cutterblock

guard extrusion exactly to the

dimension of the work piece.

− Never reach with your hands

under the cutterblock cover when

guiding the work piece!

− Use a feeding aid (push block)

when planing small workpieces,

which can not be guided with a

sufficient safety distance to the

cutterblock.

− Use the jointer fence when edge

jointing to have safe lateral sup-

port and guiding. Use an auxiliary

fence when planing thin or nar-

row stock, to have your hands at

a sufficient safety distance to the

cutterblock.

− Use a stop block behind the work

piece for set-in work, to keep the

work piece from being thrown

back against the direction of feed.

− Use a work piece support (e.g.

roller stand) to keep long stock in

balance.

− Do not pull the work piece back

over the unguarded cutterblock!

− Use if necessary:

Dust collection device (optional

accessory);

sliding wax to enhance the glid-

ing of work pieces across the

infeed and outfeed table.

1. Assume proper operating position:

− on the switch side;

− head-on to the machine;

2. Set jointer fence as required.

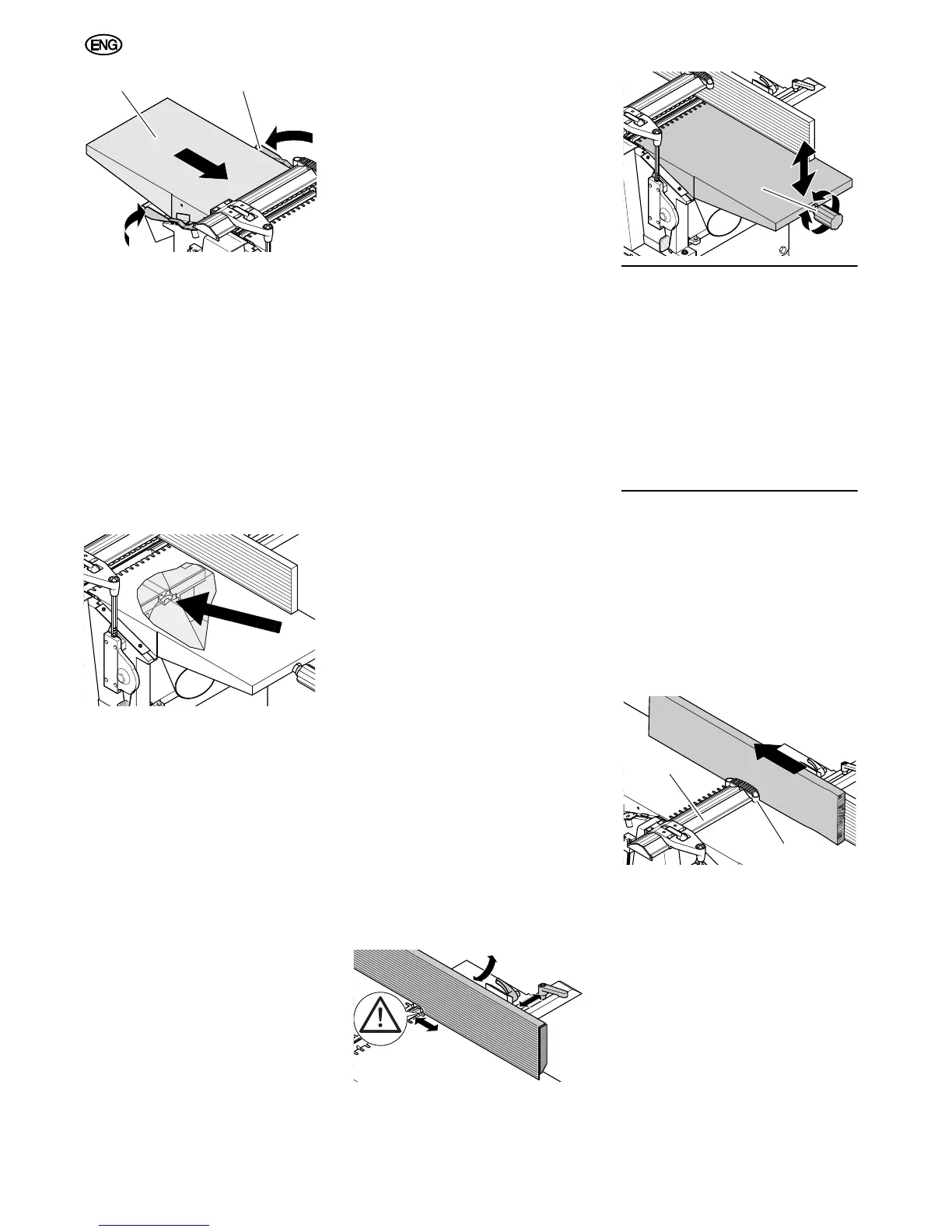

3. Set depth of cut with starknob screw

(56) on the infeed table.

3

Note:

The machine can remove 3 mm

maximum in a single pass. This meas-

ure, however, shall only be used:

− with very sharp planer knives;

− for soft woods;

− if the full planing width is not utilized.

Otherwise there is a risk of overloading

the machine.

It is best to make several passes to bring

the work piece down to the desired thick-

ness.

4. Place work piece against jointer

fence (if required, use auxiliary

fence).

5. Adjust cutterblock guard extrusion:

− Planing small edges (jointing):

Slide the cutterblock cover extru-

sion (57) from the side against

the work piece – the spring (58)

at the end of the cutterblock

cover extrusion should be slightly

depressed.

− Planing wide surfaces:

Lower the cutterblock cover

extrusion (59) from above onto

the work piece.

54

55

5656

57

58

Loading...

Loading...