20 7 ND91H 70 en

6.2.2 Installation

❑ Ensure that the gasket (174) is properly located

in the groove on the bottom of the spool valve

assembly. Mount the spool valve assembly on to

the housing and tighten the M3 and M4 screws

evenly. Ensure the O-ring (140) slots inside the

groove fully. Mount the prestage unit directly on

the spool valve unit as in 6.1.

6.3 Communication circuit board

6.3.1 Removal

❑ Loosen the M8 grub screw (110) off the position

indicator (109) and turn the position indicator

from the shaft. Remove the cover off the prestage

(43). Remove the cover of the circuit boards

attached with M3 screws (42, 4 pcs).

❑ Remove the M3 screws (217, 4 pcs.). Hold the

sides of the circuit board and lift it directly

upwards and outwards. Handle the board care-

fully, touching only the sides.

6.3.2 Installation

❑ Mount the new communication circuit board

carefully.

❑ Locate the pins with the matching connector on

the board. Tighten the M3 screws (217) evenly.

❑ Install the cover of the circuit boards and the

cover of the prestage (43).

❑ Mount the position indicator (109) on the shaft

and tighten the M8 screw (110) temporarily. The

final orientation and locking of the position indi-

cator should be done after installation of the

valve controller to the actuator.

7 ERROR MESSAGES

7.1 Failsafe errors

7.2 Alarms

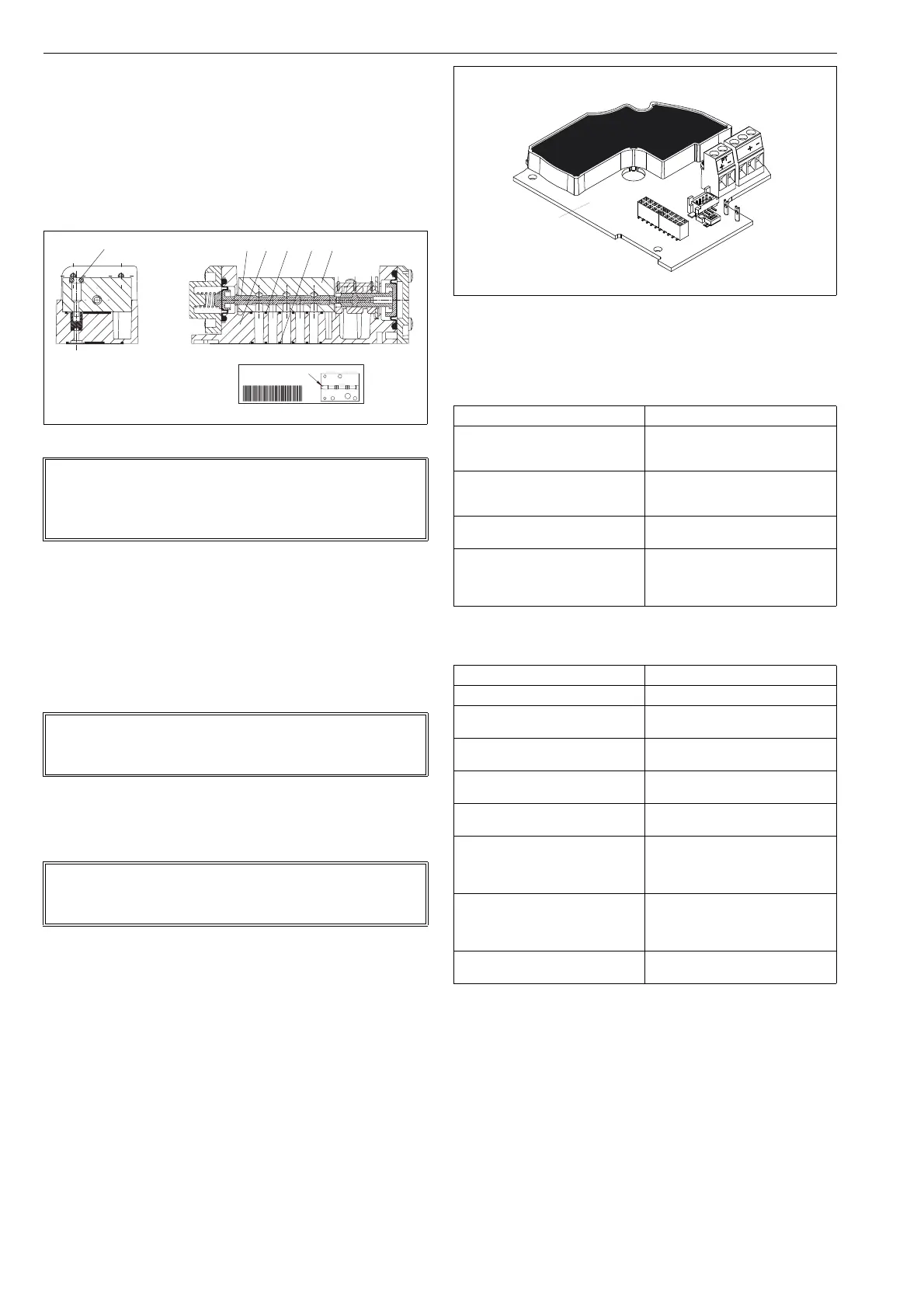

Fig. 22 Spool valve assembly

NOTE:

If the maintenance operations have been done for the

spool valve assembly, the device must always be cal-

ibrated and tuned.

NOTE:

Ground yourself on the body of the device before

touching the circuit board.

NOTE:

Do not remove the Valve Controller Board (210)!

Removing the board will void the warranty.

195 194140 160 174 175

0327000170

Assembly direction of spool

Sticker on fastener (160)

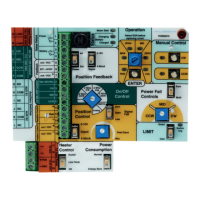

Fig. 23 Communication board

Display message Description

POSITION SENSOR FAILURE Position sensor measurement

failed. Change the ND9000

device to a new one.

SETPOINT SENSOR

FAILU RE

mA measurement failed.

Change the ND9000 device

to a new one.

PRESTAGE SHORTCUT

ERROR

Shortcut in the prestage unit.

FAE nnn Fatal malfunction in the device.

nnn is a number between 001 -

004. Change the ND9000

device to a new one.

Display message Description

DEVIATION ALARM Valve deviation out of limits.

STICTION LOW ALARM Stiction has exceeded the

low limit.

STICTION HIGH ALARM Stiction has exceeded the

high limit.

LOAD FOR OPENING LOW

ALARM

Load for opening has

exceeded the low limit.

LOAD FOR OPENING HIGH

ALARM

Load for opening has

exceeded the high limit.

SPOOL VALVE PROBLEM Spool valve problem in the

controller. Check the spool

valve unit and replace if

necessary.

PNEUMATICS PROBLEM Inconsistent actuator

pressures. Check pneumatic

connections and actuator

leakage.

FRICTION PROBLEM Valve is not moving correctly.

Check load factor.

215

Loading...

Loading...