ADJUSTMENTS

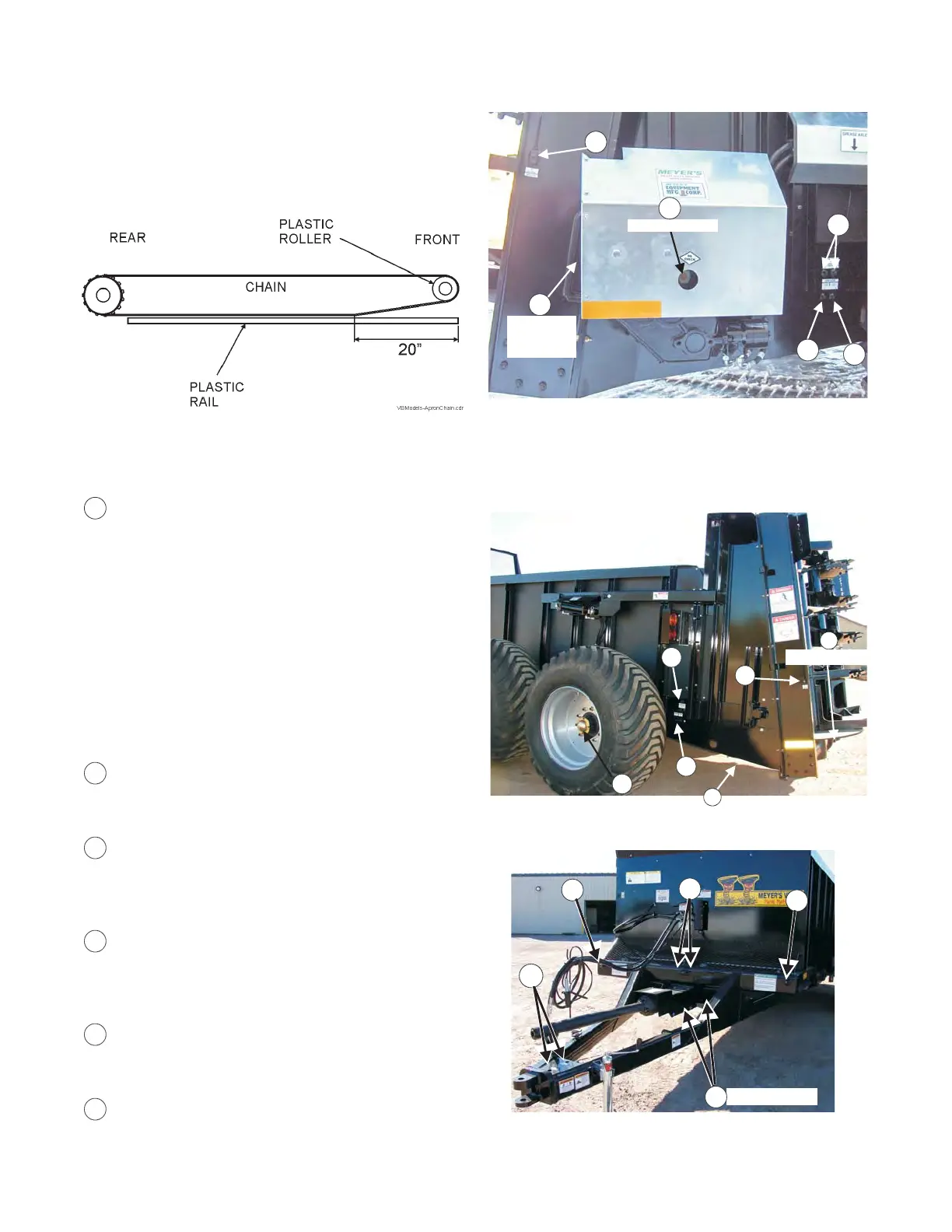

Apron Chain

The apron chain is adjusted by (4) adjuster bolts

located on the front of the box frame, figure 13. Adjust

the 1-1/8” bolts so the chain is elevated above the

plastic slide rails for 36” as illustrated on figure 10.

When there is no more adjustment left on the adjuster

screws, loosen the nuts on the bolts and push the

bolts in as far as they will go. Then remove a link from

each chain and readjust the apron chain

NOTICE! Chain must run centered on the front nylon

rollers.

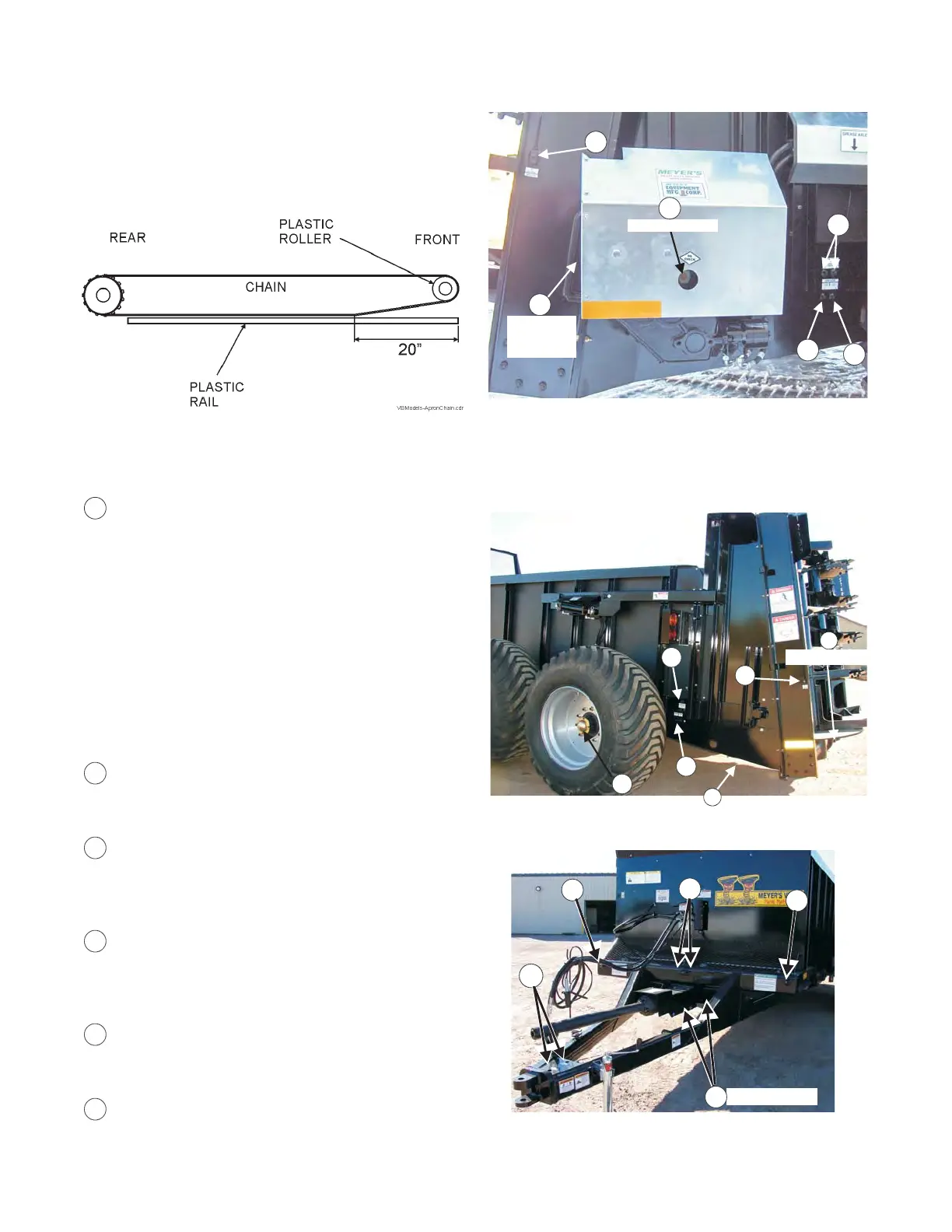

LUBRICATION

Grease bearings on top of Vertical Beater one pump

every 8 hours, both sides by grease lines. Figures 11 and

12.

Maintain oil level in apron drive reducer at check

level plug, accessible at right, rear side. It holds 6 Qts.

When required, refill with SAE 85-140 Moly Fortified

gear lube or Synthetic SAE 75-90 gear lube. Figure 11.

Grease 3 bearings on the drive shaft under spreader

box, one pump every 8 hours. These bearings are ac-

cessed by grease lines, 3 places on RH side of machine.

Figures 11 and 14.

There are two bearings at the front of the driveline

connecting to the PTO shaft. Grease these bearings

one pump every 8 hours. Figure 13.

Grease Pivot Hitch 2 pumps every 8 hours, each

grease zerk. Figure 13.

MODEL: VB750 Page 20

FIGURE 10. ADJUST APRON CHAIN

FIGURE 11.

SIGHT GLASS

REMOVE

SHIELD

FIGURE 12.

SIGHT GLASS

FIGURE 13.

UNDERNEATH

Loading...

Loading...