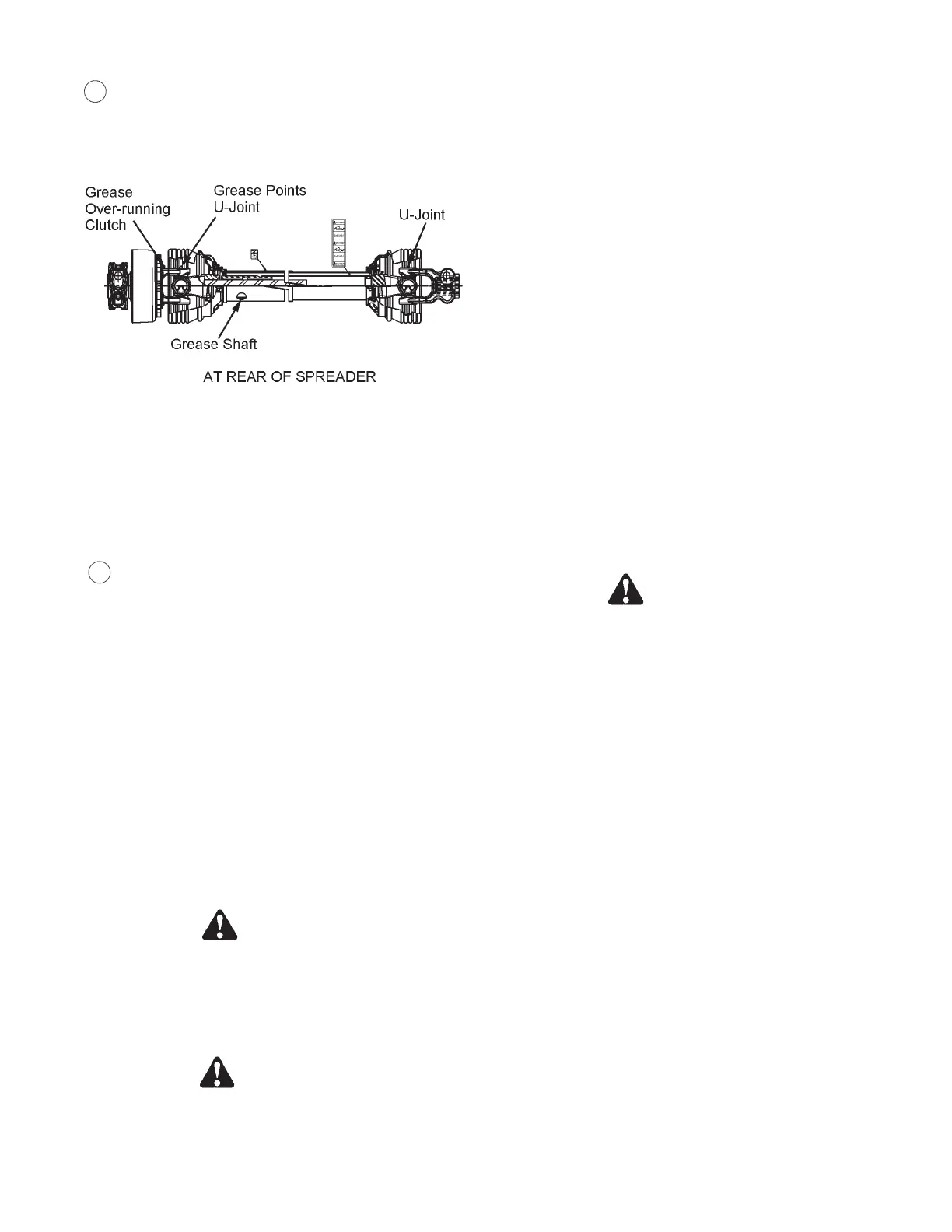

Grease the over running clutch 3-4 pumps every

8 hours. Figure 16. Located at rear of spreader.

Grease cross bearings on yoke (both ends of connect-

ing driveline to vertical beater). 1 pump every 8 hrs. This

is accessible below spreader box, 1 zerk on overrunning

clutch. See figure 16.

Remove the wheels and hubs annually. Figure

12. Clean out old grease and repack bearing cones

with quality EP grease. Put a ¼” film of grease on the

bearing cups and reassemble. If your hubs have

grease zerks, do not lube them. Grease builds up in

the hub and eventually will damage the seal when ex-

pansion from heat occurs. Figure 12.

NOTICE! RE-LUBRICATE AT REGULAR INTERVALS

TO PREVENT DAMAGE TO THE BEARINGS.

RE-LUBRICATION INTERVALS ARE VERY DIFFI-

CULT TO DETERMINE, DEPENDING ON USAGE.

THE GEARBOX HOUSINGS SHOULD BE KEPT AP-

PROXIMATELY 1/3 TO ½ FULL WHICH CORRE-

SPONDS WITH THE CHECK PLUG OR GAUGE.

CLEANING AND STORAGE

WARNING

DISCONNECT PTO DRIVE SHAFT AND HYDRAULIC

HOSES BEFORE CLEANING, ADJUSTING OR SER-

VICING THIS MACHINE. FAILURE TO HEED MAY

RESULT IN SERIOUS PERSONAL INJURY OR

DEATH.

WARNING

APRON STARTS AUTOMATICALLY WHEN GATE

OPENS.

Before storing this spreader for an extended period of

time, perform the following:

1. Allow the spreader to completely clean out the last load.

2. Thoroughly hose off all manure from the outside of

the spreader and the inside of the box, particularly get-

ting the end gate mechanism clean. The water can be

drained into your manure storage pit or if the gate is left

closed, the water can be taken to the field and spread.

3. If pressure washing spreader, be careful not to

wash directly on or too close to any bearing seals. The

high pressure can destroy the seal and force water

into the bearing causing it to rust and fail. Avoid pres-

sure washing painted areas of the spreader too close

with the washer as the pressure can strip paint on

scratched areas caused from scraping clean.

4. Manure is very acidic and should not be left on

painted areas for a long period of time because it will

lift paint from the metal. Unpainted metal will corrode

causing holes to rust through metal guards or even fall

off the machine. If this should happen, guards must be

replaced immediately.

WARNING

DO NOT OPERATE SPREADER WITH ANY GUARD

OPEN OR MISSING. ROTATING PARTS CAN DIS-

MEMBER OR KILL.

5. After cleaning, lube the spreader to exclude mois-

ture from bearings and prevent condensation from

forming during storage. Apply oil to roller chain drives.

6. This is a good time to inspect all adjustments and

check for parts that need repair or replacement. Per-

forming these tasks now will guarantee that the

spreader is ready for use at the beginning of the next

season.

MODEL: VB750 Page 22

FIGURE 16.

Loading...

Loading...