ELECTRO LIFT

®

UNIT COMPONENTS

MOTORS ( 3”) E-46, E-46H and E-47, E-47H

The 12-volt DC high torque motor used on the Electro

Lift

®

units are interchangeable among all four models.

Its function in all four applications is to drive the

hydraulic pump. The motor is only energized and

operating when pressurized hydraulic fluid is required.

Two different brand motors were used. While they are

interchangeable and have nearly identical performance

characteristics, they have distinctive design differences.

American Bosch

The American Bosch motor is a four pole, permanent

magnet motor which consists primarily of a 3" diameter

solid steel frame, armature, brushes and ceramic

permanent magnet fields. Because the fields are

permanent magnets, they do not require electrical

current to operate. Therefore, the motor requires lower

amperage to produce a given amount of power.

Electro Lift

®

units equipped with an American Bosch

motor cannot be used on vehicles with a positive

ground electrical system since the motor will rotate

backwards. Positive ground vehicles will require

modification of the brush assembly.

Prestolite - (obsolete)

MOTOR (4-1/2”) E-57, E-57H

Iskra - Single and Two terminal

The Iskra motor is a four pole, electromagnet motor

which consists primarily of a 4-1/2" diameter solid steel

frame, armature, brushes, field coils and pole pieces.

This motor can be used on vehicles with either the

common negative ground electrical system or the

positive ground electrical system.

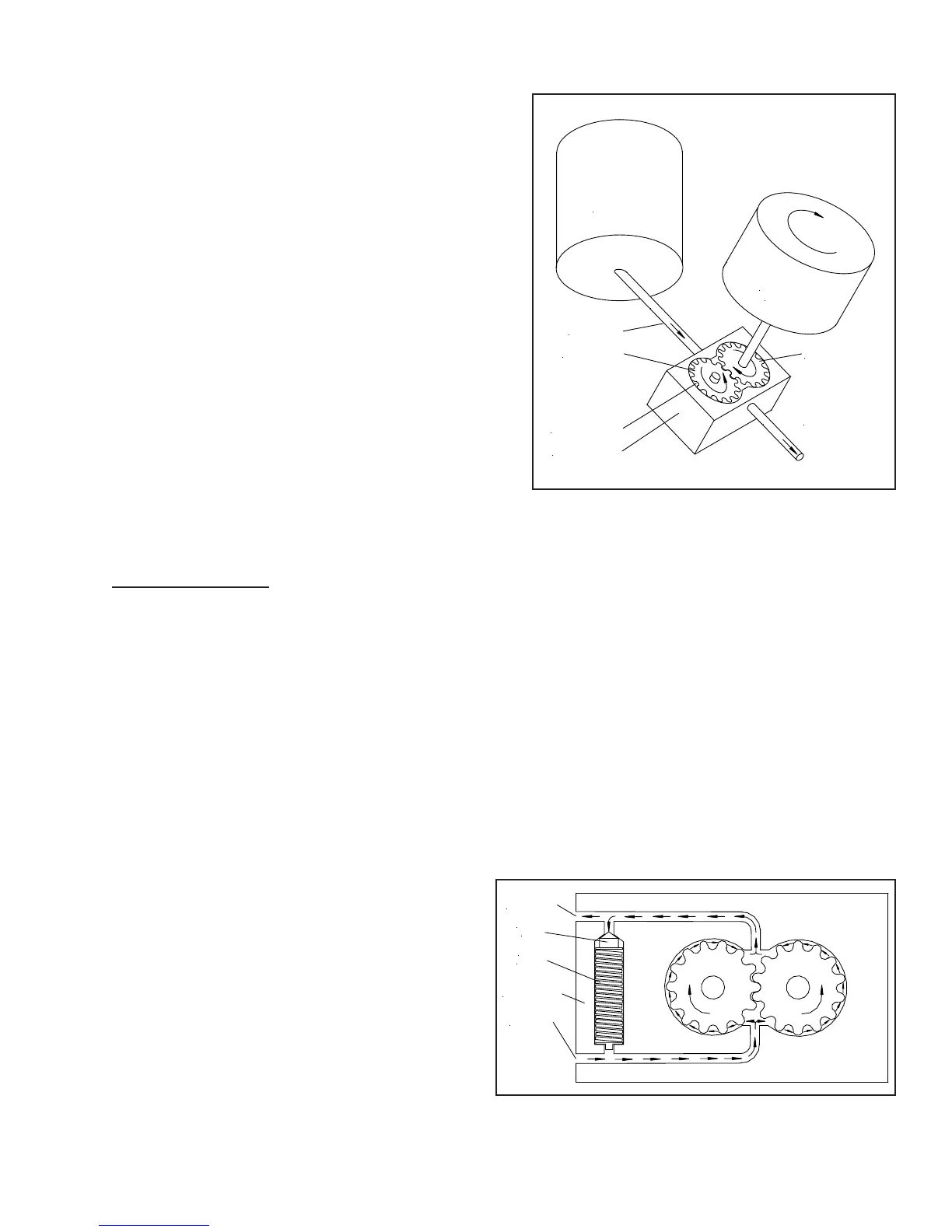

HYDRAULIC PUMP

The pump in a hydraulic system employs an external

source of power to apply a force to a liquid. A pump

develops no power of its own. It simply transfers power

from an external source (the electric motor on the

Electro Lift

®

unit) to the liquid in the hydraulic system.

The basic operating principles of the hydraulic pump

used in the Electro Lift

®

units are quite simple. Figure

1-7 illustrates the basic components of a positive

displacement gear type pump and their functions. The

pumping action takes place within the pump chamber

which is connected to the reservoir by the intake line.

The pump chamber has an outlet line in which the liquid

under motion and pressure leaves the pump to perform

work.

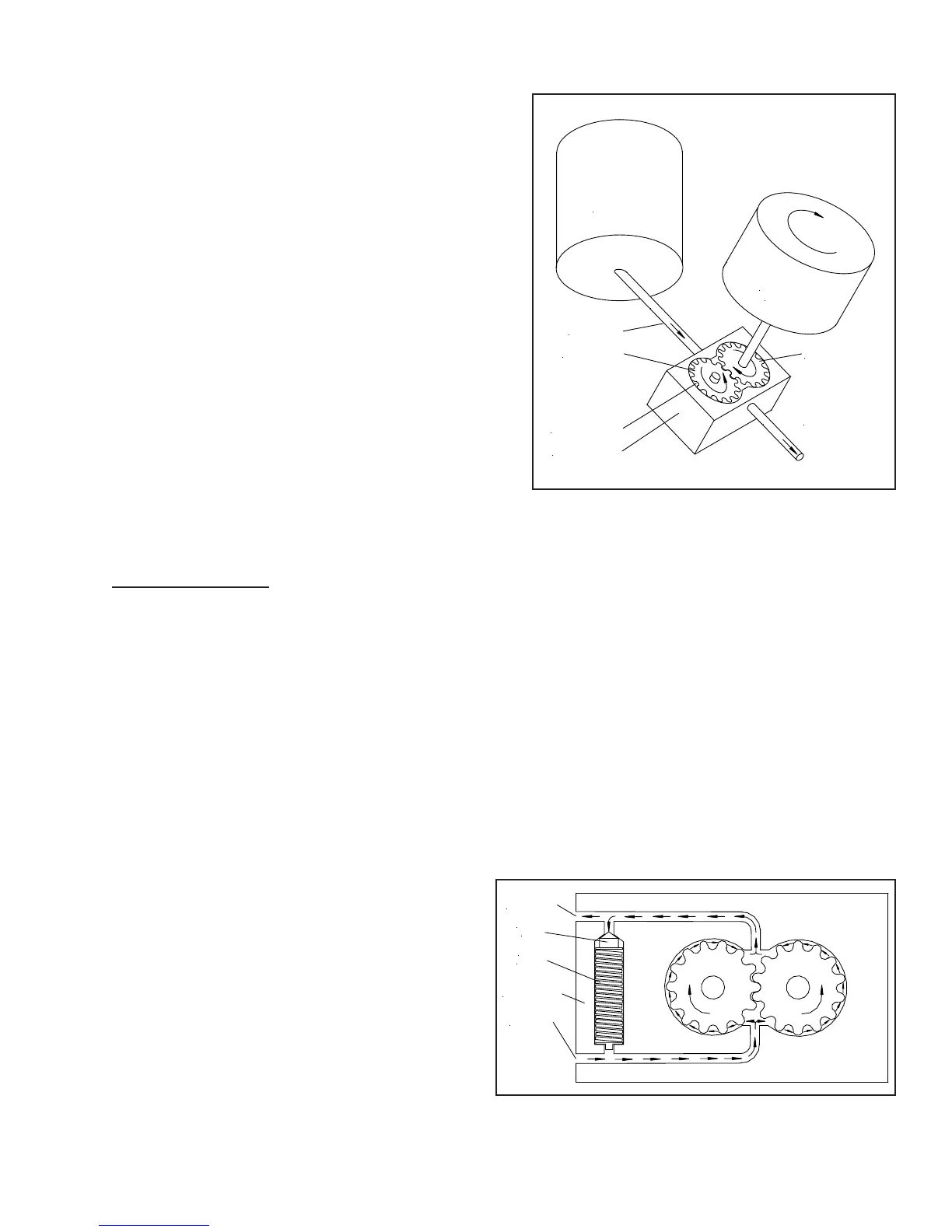

PRESSURE RELIEF VALVE

A basic pressure relief valve is shown in

Figure 1-8. It consists of a poppet valve and a valve

spring. Both are located in a passage which connects

the inlet passage to the outlet passage. The poppet

valve is normally held closed by the valve spring,

sealing the connecting passage from the pressurized

outlet passage. The poppet valve, being a piston, is

exposed to the pressurized hydraulic fluid in the outlet

passage. Whenever the hydraulic pressure against the

poppet valve becomes greater than the pressure being

exerted on the poppet valve from the opposite

direction by the valve spring, the poppet valve will

open. This allows some of the pressurized hydraulic

fluid to flow through the connecting passage to the

non pressurized inlet passage. The effect is to lower

the pressure in the outlet passage which will allow the

valve spring to close the poppet valve again.

FIGURE 1-7

ELECTRO LIFT® UNIT COMPONENTS

RESERVOIR

ELECTRIC

MOTOR

F

L

O

W

OUTLET LINE

INTAKE LINE

PUMP CHAMBER

PUMP HOUSING

DRIVE GEAR

DRIVEN GEAR

F

L

O

W

OUTLET PORT

POPPET

VALVE

VALVE

SPRING

PUMP HOUSING

INLET PORT

FIGURE 1-8

-19-

Loading...

Loading...