Under a condition, such as when a hydraulic cylinder

is extended to the end of its stroke, eliminating

additional space for the pressurized hydraulic oil to

be pumped into, the alternate opening and closing of

the poppet valve controls the pump’s pressure output

and provides an escape for the pressurized hydraulic

fluid.

The pressure relief valve used in the Electro Lift

®

pump,

while more sophisticated than the one described,

functions in the same manner. The pump pressure relief

valve may be adjusted on the E-46 & E-47 models to

the specified pressure of 1650 P.S.I. by adjusting the

set screw after installing a suitable pressure gauge of

2500 P.S.I. in the circuit. Note: The E-57 Model has a

nonadjustable pressure relief valve and is factory set

to 2000 P.S.I.

SOLENOID VALVES

Hydraulic valves are simple in concept and all have

the same basic function: Control the direction of oil

flow. One type of Solenoid Valve is used on the models

E-46 and E-46H and three types are used on models

that Power Angle.

Each Solenoid Valve consists of two components: the

Cartridge and the Coil.

Cartridge

The Cartridge consists of the hydraulic valve

mechanism and an armature which enables the

valve mechanism to be operated and controlled

electrically. The Cartridge is designed to screw in

and out of the Electro Lift

®

units much like the

typical “spark plug”.

Coil

The Coil is the electrical component which operates

the Cartridge’s valve mechanism by producing

magnetism which pulls the Cartridge’s armature

toward it. Since the armature is connected to the

valve mechanism’s only moving part, it is pulled

by the armature.

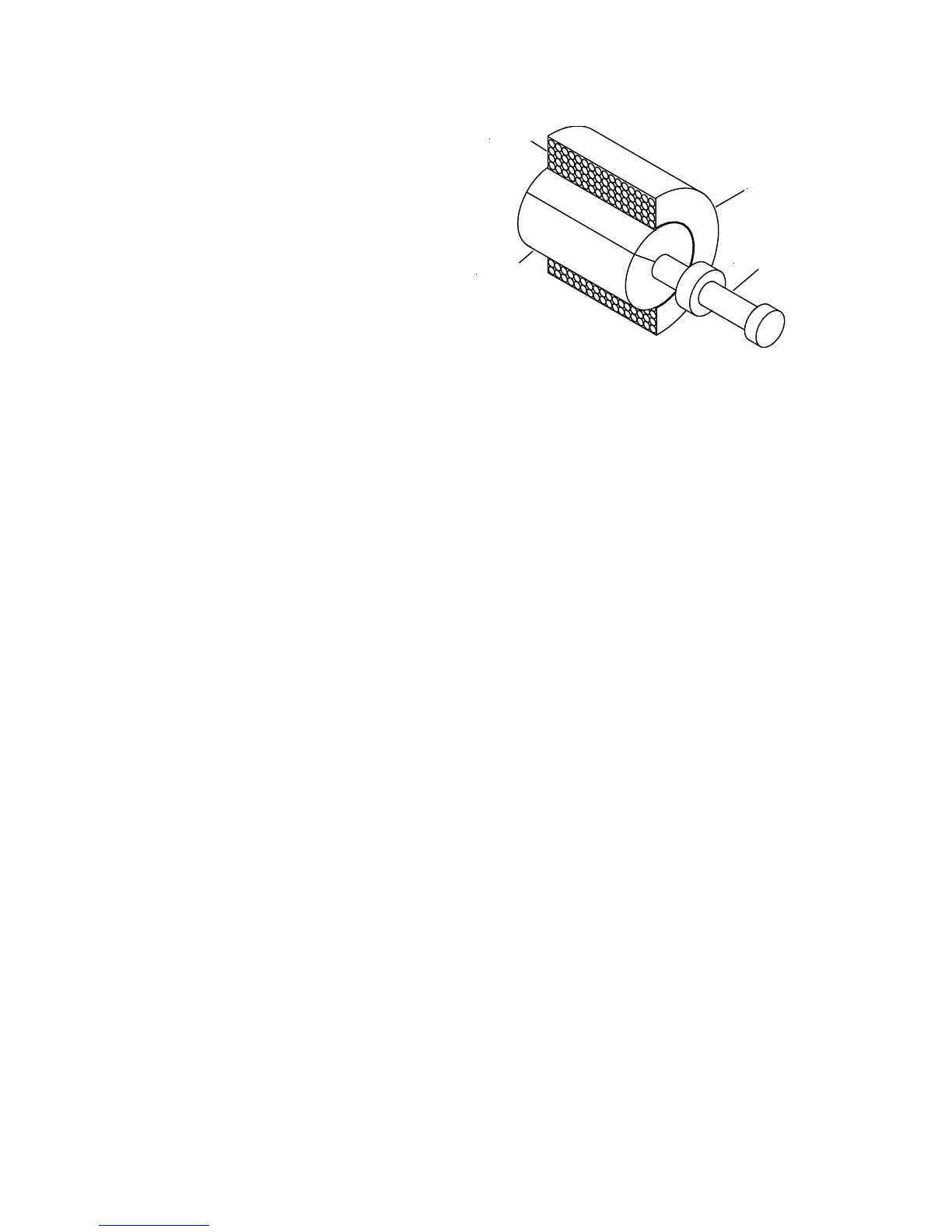

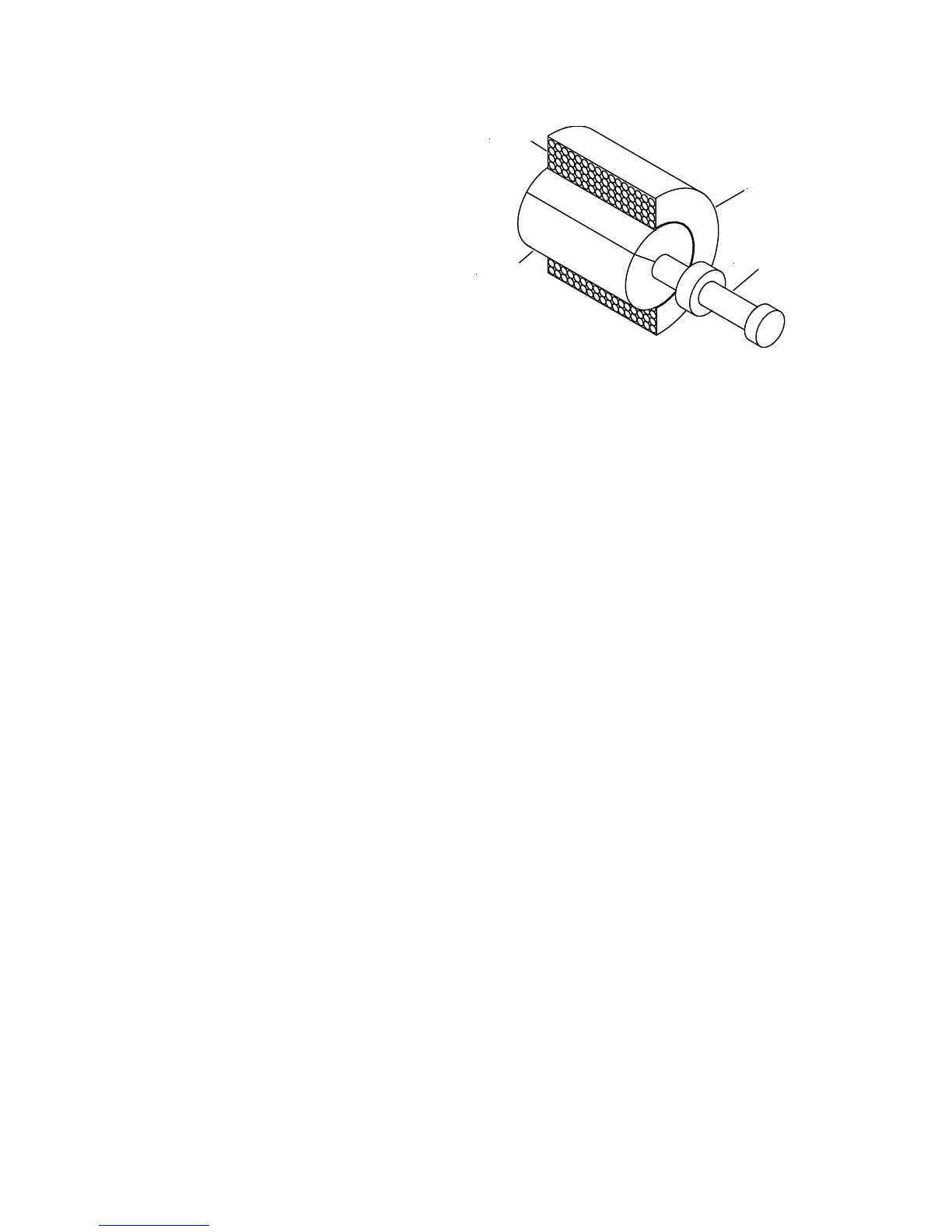

Figure 1-9 illustrates the typical Coil. Whenever

electrical current flows to the Coil, it flows through

the winding, which consists of numerous turns of

copper wire. The flow of current through the

winding produces a magnetic field which pulls the

soft iron armature further into the Coil.

The armature pulls the valve spool or poppet valve

into its alternate (energized) position. Not illustrated

is an integral coil spring, which is compressed

when the armature is pulled by the magnetism.

When the current flow ceases, the magnetic field

disappears and the compressed coil spring pushes

the armature back to its original (de-energized)

position.

FIGURE 1-9

COIL

VALVE SPOOL

WINDING

ARMATURE

“A” Solenoid Valve

The “A” Solenoid Valve is used in all Models. The “A”

Cartridge contains a poppet valve whose static or

de-energized position is closed. Its energized position

is open.

On all four models, the “A” Solenoid Valve retains

hydraulic fluid in the lift cylinder. It is energized

(opened) to allow the hydraulic fluid to flow from the

lift cylinder back to the reservoir, enabling the plow to

lower by gravity.

The “A” Solenoid Valve is designed to remain energized

(open) while the plow is lowered, plowing snow. This

is the “float” feature which insures that the plow

maintains contact with the ground contour.

“B” Solenoid Valve

The “B” Solenoid Valve is used on the Power Angle

Electro Lift

®

models. The “B” Cartridge contains a

spool valve whose static (de-energized) position allows

the pressurized hydraulic fluid to flow to the

“C” Solenoid Valve. In the energized position, the

pressurized hydraulic fluid is diverted to the lift cylinder,

raising the plow.

“C” Solenoid Valve

The “C” Solenoid valve is used on the Power Angle

Electro Lift

®

models. The “C” Cartridge contains a

spool valve whose static (de-energized) position allows

the pressurized hydraulic fluid to flow to the right power

angling cylinder which angles the plow to the left. At

the same time, it allows the hydraulic fluid being forced

from the retracting left power angling cylinder to flow

through the “C” Cartridge back to the reservoir.

In the energized position, the pressurized hydraulic

fluid is diverted to the left power angling cylinder,

angling the plow to the right. Also, the hydraulic fluid

being forced from the retracting right power angling

cylinder flows through the “C” Cartridge back to the

reservoir.

-20-

ELECTRO LIFT® UNIT COMPONENTS CONT.

Loading...

Loading...