Meyer Manufacturing Corporation - 28 - PB-MIXER-TR-MECH

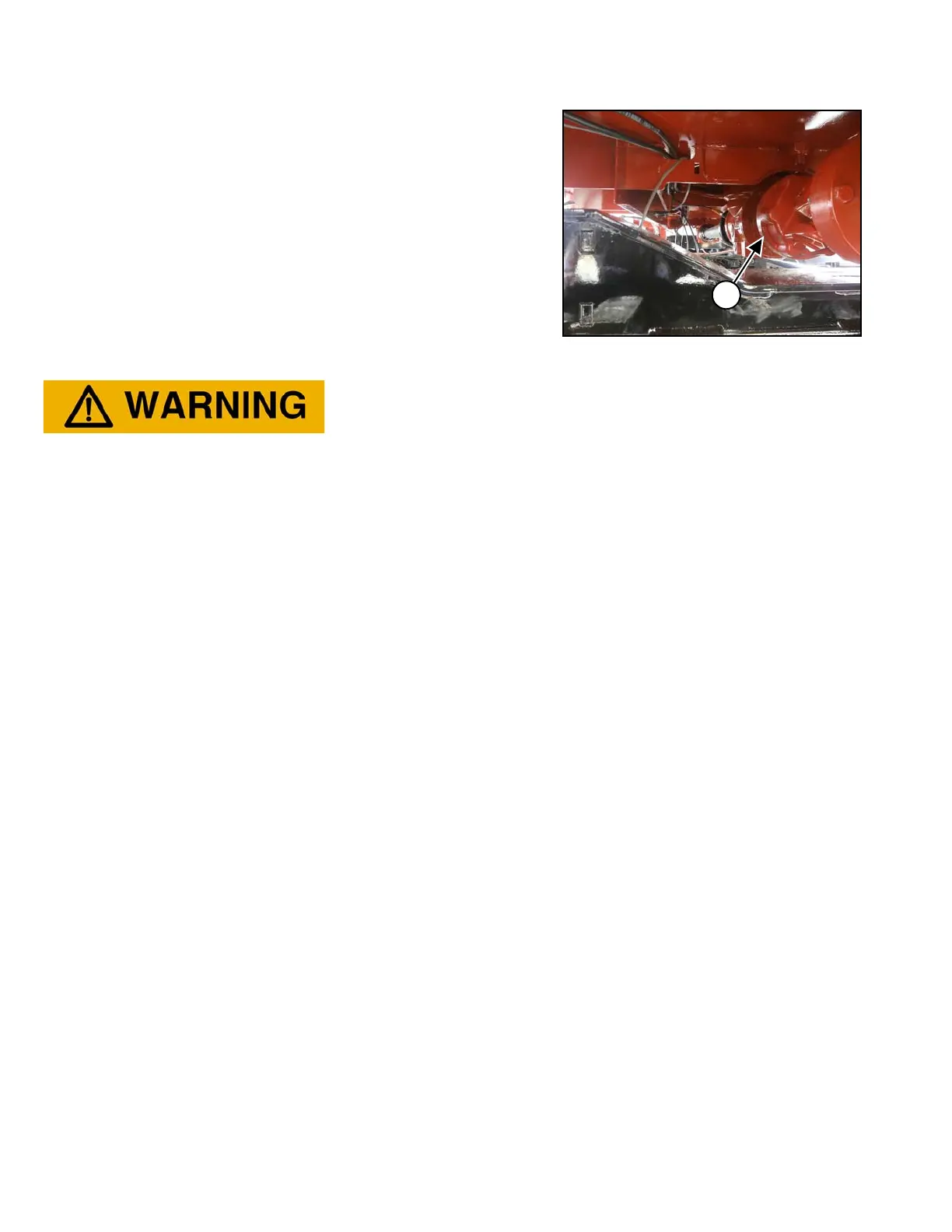

7.1.1 Cutout Clutch

The clutch is designed to limit the amount of torque transferred to the

machine through the driveline. If excessive torque is developed the clutch

will disengage. A loud ratcheting sound will be heard and the transfer of

power to the machine will be disrupted. This may occur when mixing or

unloading a heavy mix or if an obstruction has lodged within the mixer.

This is to protect the driveline from damage. Remove obstruction or

reduce load weight. To re-engage the machine, simply shut down the PTO

and allow the driveline to come to a stop. The PTO can then be re-

engaged to restart the mixer. The cutout clutch will either re-engage upon

shut down of the PTO or just before it comes to a complete stop.

7.1.2 Material

Some feed materials will need to be processed alone in the mixer before they can be efficiently mixed with other feed

materials.

• Large square or round bales of alfalfa

• Large square or round bales of high moisture content

• Large square or round bales of long mixed grasses, wheat or oat hay and crop residue bales (straw or soybean

stubble)

• Very light and bulky feed material

NOTE: Always remove any twine, net, or plastic wrap from bales before loading into mixer.

NOTE: It is highly recommended that after loading the mixer, the process continues until the material is fully

unloaded.

Never hand feed material into mixer while it is running. Augers may

cut or grab hands, clothing, or material being loaded, causing severe

injury. Always stop the engine before hand loading materials.

Loading...

Loading...