21

never force them over the side of the pulley. Always loosen the motor

to install them. Over tensioning of belts may cause premature failure.

5. When one or more of the belts is worn out, put on a COMPLETE set

of new belts.

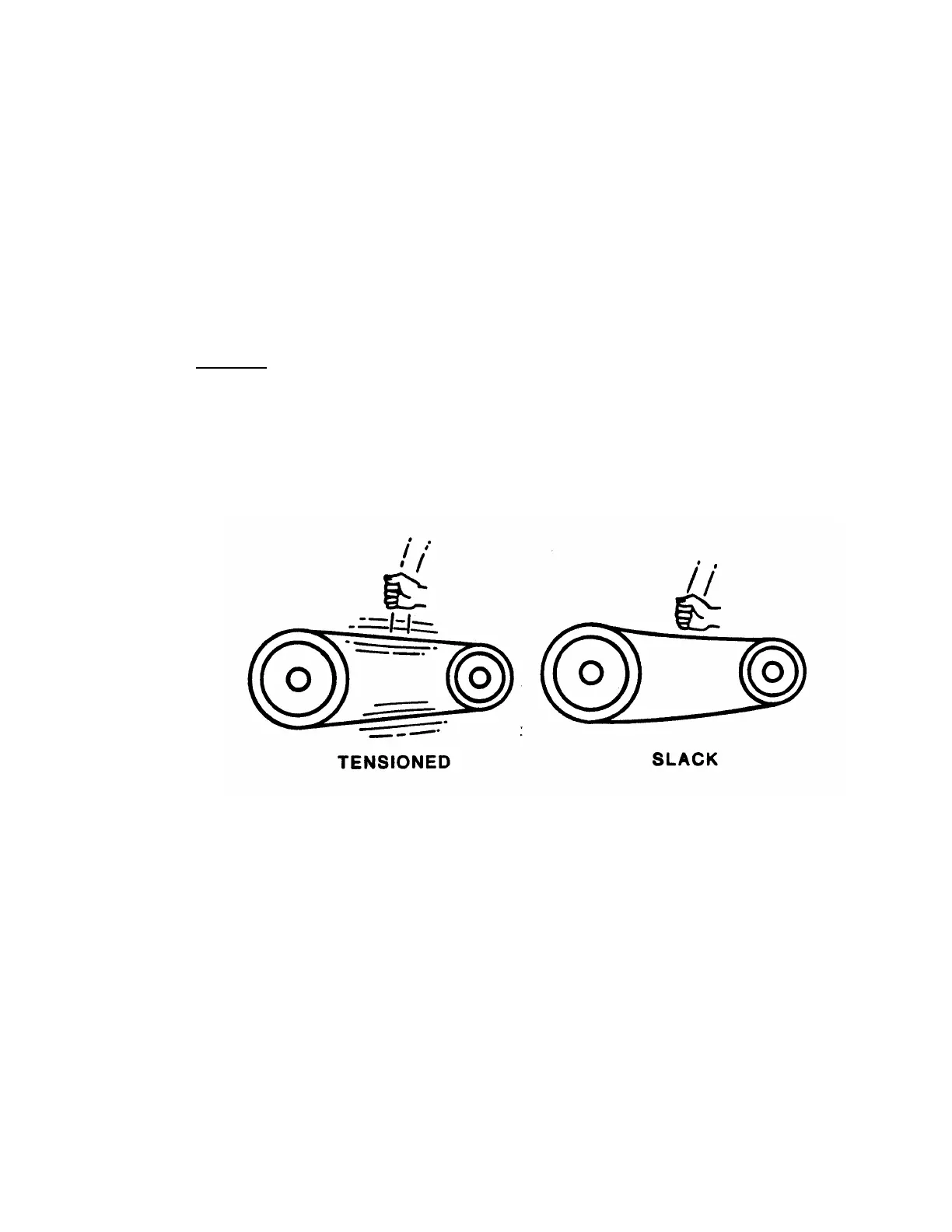

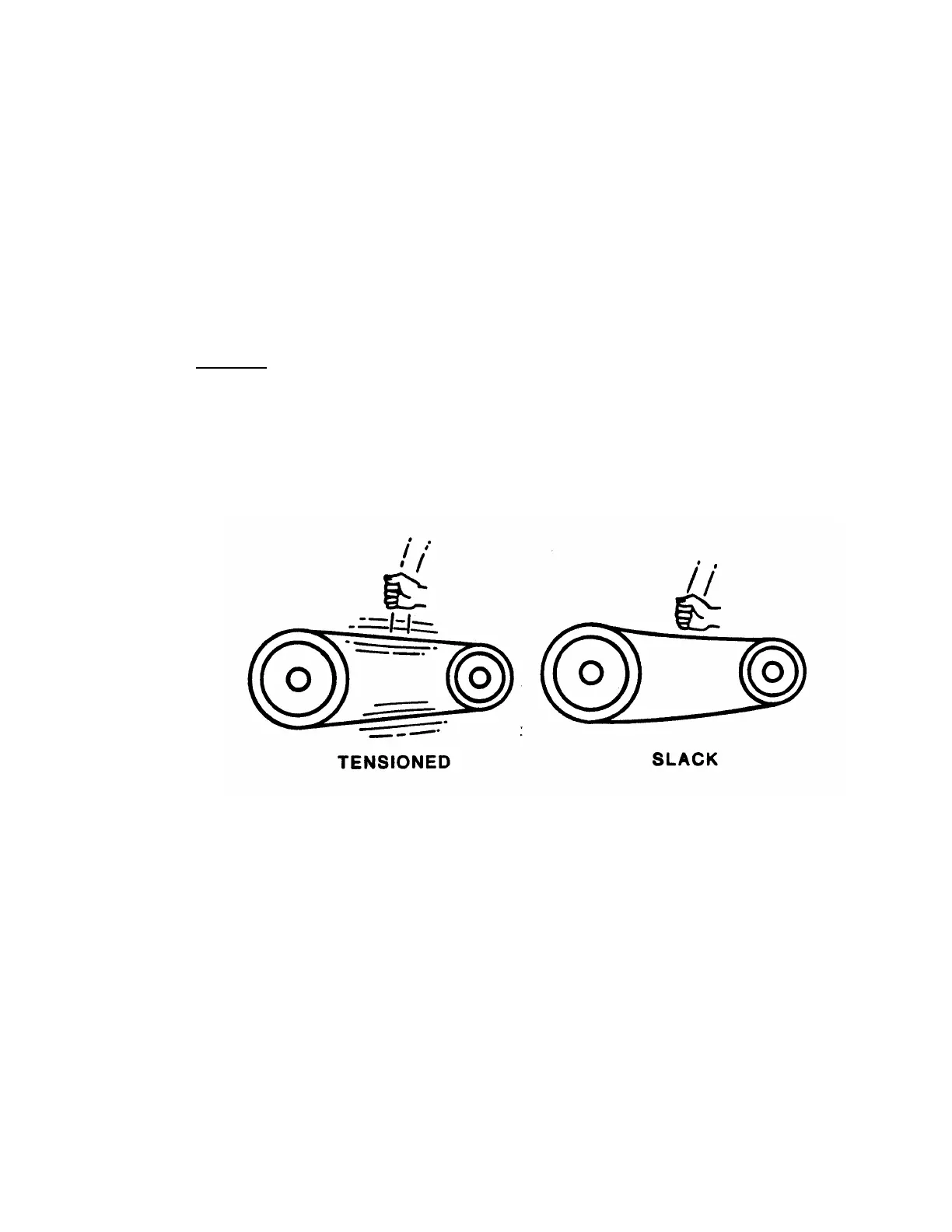

6. A good way to check belt tension is to strike the belts with a clench

fist. A slack belt will feel dead under this test, whereas a properly

tensioned belt will vibrate and feel alive. Check the belt tension from

time to time. See Figure 11

Warning: Never run unit with belt guard removed and never check belt tension while

unit is running. Such unsafe practices can result in injury or death.

The working life and proper functioning of the belts depend to a high degree on how

they are cared for. Oil and grease will soon ruin them. Oily or greasy belts can be

cleaned with a good solvent.

3.6 G.S. Coupling

Solids overloading can cause excessive torque between the bowl and conveyor. This

torque could damage the gearbox if the overload became too severe.

Loading...

Loading...