39

1. Remove screws (58). Remove the tapered lock ring (57).

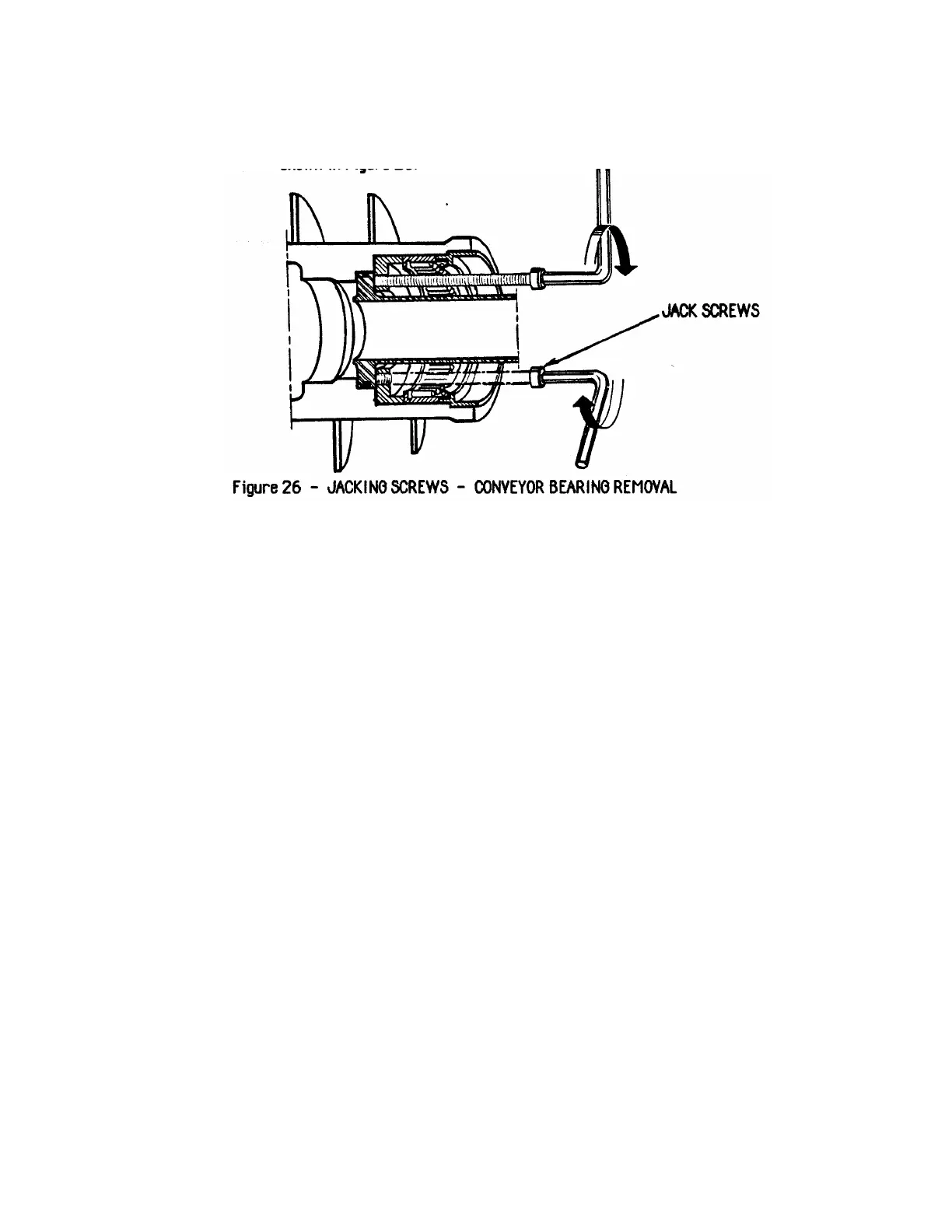

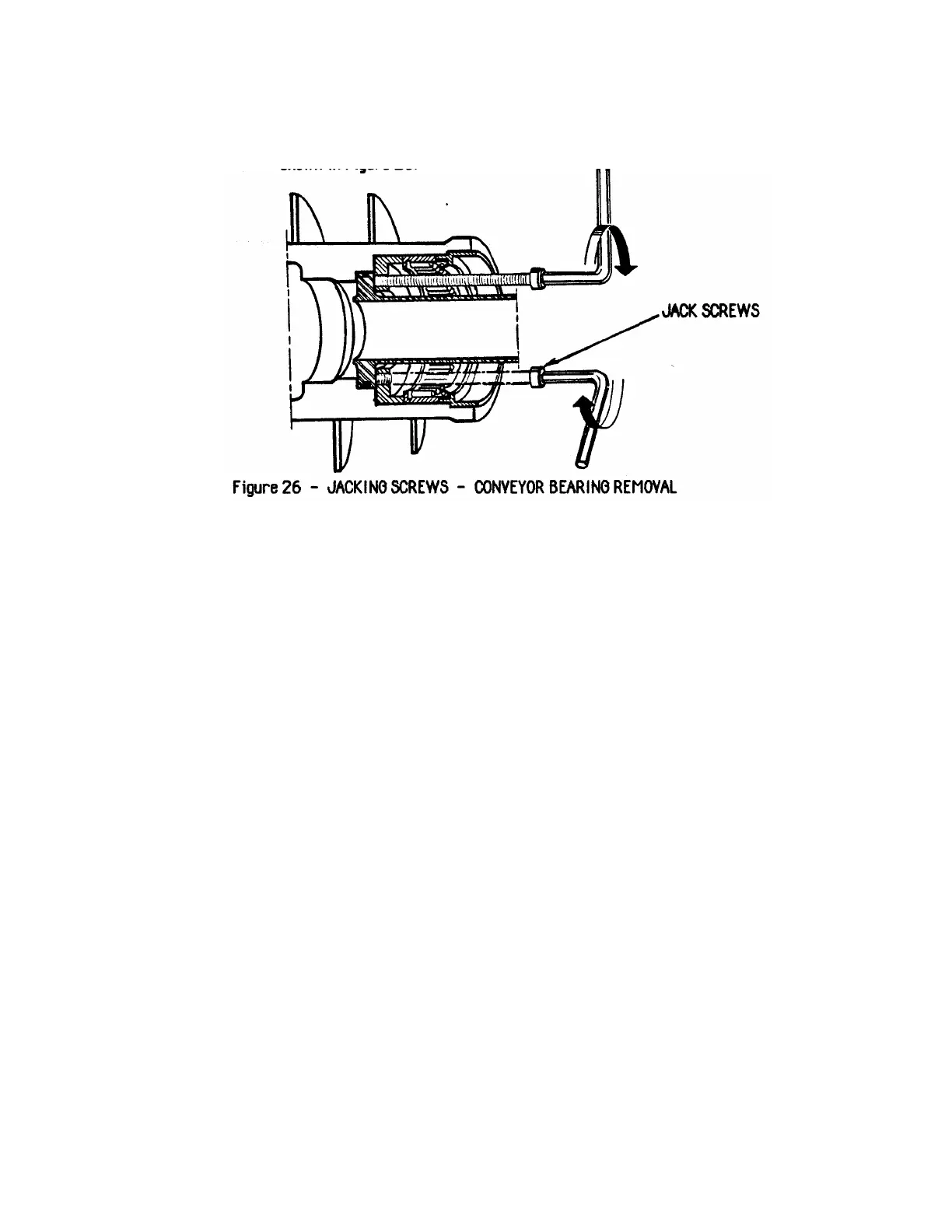

2. Using the jack screws (P/N: 96-01-011) ease out the ejector disc (52).

3. If necessary the protecting tube (50) can be removed. Inspect parts

carefully and replace if necessary.

5.2.11 Assembly Small Conveyor Bearing

The procedure for assembling the small conveyor bearing is as follows.

Refer to Figure 22.

1. If the protecting tube (50) was removed, a new o-ring (49) should be

installed. Apply grease on the o-ring before installation.

2. Install the ejector disc (52) observing alignment of pin on flange of

protected tube (50).

3. Install shims (53) the number and thickness as those removed.

4. Install the bearing outer race (54).

5. Apply grease on o-ring (33). Install o-ring in the groove of the bearing

cavity of the conveyor.

6. Install a new lip seal ring (35) in the seal lining (56). Check that

sealing lip is turned the correct way.

7. Install the seal lining (56) by pressing it evenly into its seat. The seal

lining should be pressed in straight to prevent damage to the o-ring.

Use drift tool (P/N: 96-01-027) to press seal lining into conveyor. See

Figure 27.

Loading...

Loading...